Vergleich zwischen Schraubenfedern und Druckfedern: Struktur, Belastungsverhalten, Ermüdungslebensdauer, EMI-Abschirmungsleistung und Anwendungen, um Ingenieuren die Auswahl der richtigen Federlösung zu erleichtern.

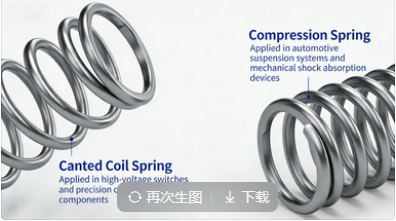

Bei der Auswahl einer Feder für feinmechanische oder elektrische Anwendungen vergleichen die Ingenieure häufig schräge Schraubenfeder vs. Druckfeder Ausführungen. Obwohl beide Federtypen dazu dienen, mechanische Energie zu speichern und Kraft bereitzustellen, bietet die geneigte Schraubenfeder im Vergleich zu einer herkömmlichen Druckfeder grundlegend andere Leistungsmerkmale.

A Schrägzugfeder wurde speziell entwickelt, um eine konstante Kraft, eine lange Ermüdungslebensdauer und eine hervorragende elektrische Leitfähigkeit zu gewährleisten. Im Gegensatz dazu werden Druckfedern häufig für allgemeine mechanische Zwecke verwendet, sind aber in Umgebungen mit hohen Zyklen und hoher Zuverlässigkeit eingeschränkt. Verstehen Sie den Unterschied zwischen einer Schrägzugfeder und eine Druckfeder sind für eine optimale Systemleistung unerlässlich.

A Schrägzugfeder ist eine Präzisionsfeder, die aus einem Endlosdraht besteht, der in Windungen geformt ist, die absichtlich im Verhältnis zur Federachse abgewinkelt sind. Diese abgewinkelte Geometrie ermöglicht jeder Windung der Schrägzugfeder bei der Kompression unabhängig voneinander zu agieren.

Die einzigartige Struktur eines Schrägzugfeder bietet mehrere mechanische Vorteile:

Aufgrund dieser Konstruktion kann ein Schrägzugfeder kann eine nahezu konstante Kraft über einen großen Arbeitsbereich aufrechterhalten.

Eine richtig konzipierte Schrägzugfeder Angebote:

Diese Merkmale machen die Schrägzugfeder ideal für Präzisions- und Hochzuverlässigkeitsanwendungen.

Eine Druckfeder ist eine herkömmliche mechanische Feder, die so konstruiert ist, dass sie einer axialen Kompression widersteht. Im Gegensatz zu einer Schrägzugfeder, Eine Druckfeder besteht aus parallelen Windungen, die sich unter Belastung gegeneinander stapeln.

Während ein Schrägzugfeder verteilt die Spannung gleichmäßig über die abgewinkelten Windungen, während bei einer Druckfeder die Spannung zunimmt, wenn die Windungen in Kontakt kommen. Dieser strukturelle Unterschied erklärt, warum eine Schrägzugfeder ist besser für Anwendungen mit hohen Zyklen geeignet.

| Merkmal | Canted Coil Feder | Druckfeder |

|---|---|---|

| Geometrie der Spule | Abgewinkelt | Parallel |

| Spannungsverteilung | Sogar | Konzentriert |

| Spule Interaktion | Unabhängig | Stapeln von Spulen |

| Reibung | Niedrig | Hoch |

Die strukturellen Vorteile eines Schrägzugfeder führen direkt zu einer überlegenen mechanischen und elektrischen Leistung.

Einer der wichtigsten Vorteile einer Schrägzugfeder ist seine Fähigkeit, die Kraft während der Kompression konstant zu halten. Dies macht die Schrägzugfeder ideal für Anwendungen, die einen stabilen Anpressdruck erfordern.

Bei Druckfedern nimmt die Kraft mit zunehmender Einfederung zu. Im Gegensatz dazu ist eine Schrägzugfeder vermeidet übermäßige Lastansammlungen, schützt die Gegenstücke und verlängert die Lebensdauer des Systems.

Da jede Spule in einer Schrägzugfeder selbständig durchbiegt, wird die Ermüdungsbelastung erheblich reduziert. A Schrägzugfeder kann Millionen von Zyklen ohne nennenswerte Leistungseinbußen überstehen.

Bei Druckfedern kommt es bei wiederholter Belastung zu Schraubenreibung und dauerhafter Verformung. Bei Anwendungen, bei denen eine lange Lebensdauer entscheidend ist, ist eine Schrägzugfeder ist eine weitaus zuverlässigere Lösung.

A Schrägzugfeder bietet einen kontinuierlichen leitenden Kontakt und gleichmäßigen Druck, was für eine wirksame EMI-Abschirmung unerlässlich ist. Aus diesem Grund ist die Schrägzugfeder wird häufig in HF-Gehäusen, Steckern und Elektronikgehäusen verwendet.

Druckfedern haben keinen gleichmäßigen elektrischen Kontakt und sind nicht für die EMI-Abschirmung ausgelegt. Im Gegensatz dazu ist eine Schrägzugfeder hält die elektrische Kontinuität auch bei Vibrationen aufrecht.

A Schrägzugfeder kann in verschiedenen Nutenformen installiert werden, darunter rechteckige, schwalbenschwanzförmige und runde Nuten. Diese Flexibilität ermöglicht die Schrägzugfeder Sie können Ausrichtungsfehler und Oberflächenunregelmäßigkeiten besser ausgleichen als Druckfedern.

Gemeinsame Anwendungen für eine Schrägzugfeder umfassen:

In jedem Fall ist die Schrägzugfeder übertrifft herkömmliche Druckfedern an Zuverlässigkeit und Lebensdauer.

Obwohl ein Schrägzugfeder Zwar sind die Anschaffungskosten höher, aber die lange Lebensdauer und der geringere Wartungsaufwand machen sie auf Dauer zu einer kostengünstigen Lösung. Für Systeme mit hoher Zuverlässigkeit ist eine Schrägzugfeder bietet hervorragende Gesamtbetriebskosten.

Unser Schrägzugfeder Produkte wurden für Anwendungen entwickelt, bei denen es auf gleichbleibende Kraft, Haltbarkeit und elektrische Leitfähigkeit ankommt.

Die wichtigsten Merkmale unserer kantigen Spiralfeder:

Jede Schrägzugfeder wird nach strengen Qualitätsstandards hergestellt, um eine wiederholbare und zuverlässige Leistung zu gewährleisten.

Der Vergleich von schräge Schraubenfeder vs. Druckfeder zeigt deutlich, dass ein Schrägzugfeder bietet eine überragende Leistung in Bezug auf Belastungsbeständigkeit, Ermüdungslebensdauer und EMI-Abschirmungsfähigkeit. Für Ingenieure, die kritische Systeme entwerfen, ist die Auswahl eines Schrägzugfeder gewährleistet langfristige Zuverlässigkeit und optimale Leistung.

FÜR WEITERE INFORMATIONEN, BITTE E-MAIL AN: sale01@handaspring.com