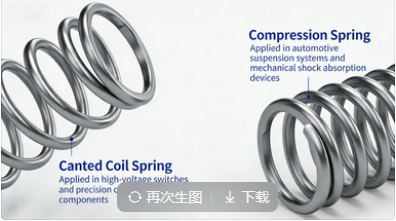

構造、荷重挙動、疲労寿命、EMIシールド性能、アプリケーションを網羅したカンテッドコイルスプリングと圧縮スプリングの比較は、エンジニアが適切なスプリングソリューションを選択するのに役立ちます。.

精密機械や電気用途のスプリングを選択する際、エンジニアは頻繁に比較します。 コイルスプリングと圧縮スプリングの比較 を設計する。どちらのスプリングタイプも機械的エネルギーを蓄え、力を提供する役割を果たしますが、カントコイルスプリングは、従来の圧縮スプリングと比較して、根本的に異なる性能特性を提供します。.

A コイルスプリング は、安定した力、長い疲労寿命、優れた電気伝導性を提供するために特別に設計されています。対照的に、圧縮スプリングは一般的な機械用途に広く使用されていますが、高サイクル、高信頼性の環境では限界があります。圧縮スプリングの違いを理解する コイルスプリング 圧縮スプリングは、最適なシステム性能を達成するために不可欠である。.

A コイルスプリング は、スプリング軸に対して意図的に角度をつけたコイルに形成された連続ワイヤから作られる精密スプリングです。この角度のついた形状により、スプリングの各コイルは コイルスプリング 圧縮時に独立して作用する。.

のユニークな構造である。 コイルスプリング にはいくつかの機械的な利点がある:

この設計のおかげで コイルスプリング は、広い使用たわみ範囲にわたってほぼ一定の力を維持することができる。.

適切に設計された コイルスプリング を提供している:

これらの特徴により コイルスプリング 精密で信頼性の高いアプリケーションに最適です。.

圧縮スプリングは、軸方向の圧縮に耐えるように設計された従来の機械的スプリングである。圧縮ばねは コイルスプリング, 圧縮スプリングは、負荷がかかった状態で互いに積み重なる平行コイルに依存している。.

一方で コイルスプリング 圧縮スプリングは、コイルが接触するにつれて応力が増加する。この構造上の違いが コイルスプリング ハイサイクル用途でより優れた性能を発揮する。.

| 特徴 | 傾斜コイルスプリング | 圧縮スプリング |

|---|---|---|

| コイル形状 | アングル | パラレル |

| 応力分布 | 偶数 | 濃縮 |

| コイルの相互作用 | 独立系 | コイルスタッキング |

| 摩擦 | 低い | 高い |

の構造的な利点 コイルスプリング 直接的に優れた機械的・電気的性能をもたらす。.

の最も重要な利点のひとつは、そのようなサービスを提供することである。 コイルスプリング は、圧縮の間中、一貫した力を維持する能力である。これにより コイルスプリング 安定した接触圧力を必要とする用途に最適。.

圧縮スプリングは、たわみが大きくなるにつれて力が大きくなる。一方 コイルスプリング 過度な負荷の蓄積を避け、相手部品を保護し、システムの寿命を延ばします。.

の各コイルは コイルスプリング は独立してたわみ、疲労応力は著しく減少する。A コイルスプリング は、大幅な性能低下なしに数百万サイクルに耐えることができる。.

圧縮スプリングは、繰り返し荷重の下で、コイル摩擦と永久変形を経験する。長寿命が重要な用途では コイルスプリング の方がはるかに信頼できるソリューションだ。.

A コイルスプリング は、効果的なEMIシールドに不可欠な連続的な導電接触と均一な圧力を提供する。このため コイルスプリング は、RFエンクロージャー、コネクター、電子ハウジングに広く使用されている。.

圧縮スプリングは一貫した電気的接触がなく、EMIシールド用に設計されていない。これに対して コイルスプリング 振動下でも電気的導通を維持。.

A コイルスプリング は、長方形、アリ溝、円形など、さまざまな溝デザインに取り付けることができる。この柔軟性により コイルスプリング 圧縮スプリングよりも、ミスアライメントや表面の不規則性に対応できる。.

一般的なアプリケーション コイルスプリング を含む:

いずれの場合も コイルスプリング 信頼性と寿命において、従来の圧縮スプリングを凌ぐ。.

しかし コイルスプリング は、初期コストは高いが、耐用年数が長く、メンテナンスの手間が省けるため、長期的には費用対効果の高いソリューションとなる。高信頼性システムには コイルスプリング は、優れた総所有コストを提供する。.

私たちの コイルスプリング 製品は、安定した力、耐久性、導電性が不可欠な用途向けに設計されています。.

キャント・コイル・スプリングの主な特徴:

それぞれ コイルスプリング は、再現性と信頼性の高い性能を保証するために、厳格な品質基準に従って製造されています。.

を比較した。 コイルスプリングと圧縮スプリングの比較 であることを明確に示している。 コイルスプリング は、負荷の安定性、疲労寿命、EMI シールド能力において優れた性能を発揮します。重要なシステムを設計するエンジニアにとって コイルスプリング 長期的な信頼性と最適なパフォーマンスを保証します。.

詳しくは sale01@handaspring.com まで。