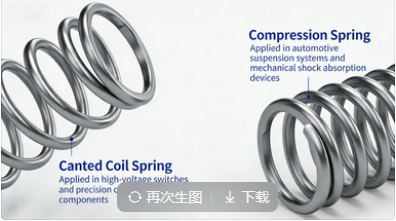

Canted coil spring vs compression spring comparison covering structure, load behavior, fatigue life, EMI shielding performance, and applications to help engineers select the right spring solution.

When selecting a spring for precision mechanical or electrical applications, engineers frequently compare canted coil spring vs compression spring designs. Although both spring types serve to store mechanical energy and provide force, the canted coil spring offers fundamentally different performance characteristics compared to a traditional compression spring.

A скошенная спиральная пружина is specifically engineered to deliver consistent force, long fatigue life, and excellent electrical conductivity. In contrast, compression springs are widely used for general mechanical purposes but are limited in high-cycle and high-reliability environments. Understanding the difference between a скошенная спиральная пружина and a compression spring is essential for achieving optimal system performance.

A скошенная спиральная пружина is a precision spring made from a continuous wire formed into coils that are intentionally angled relative to the spring axis. This angled geometry allows each coil of the скошенная спиральная пружина to act independently during compression.

The unique structure of a скошенная спиральная пружина provides several mechanical advantages:

Because of this design, a скошенная спиральная пружина can maintain a near-constant force over a wide working deflection range.

A properly designed скошенная спиральная пружина offers:

These features make the скошенная спиральная пружина ideal for precision and high-reliability applications.

A compression spring is a conventional mechanical spring designed to resist axial compression. Unlike a скошенная спиральная пружина, a compression spring relies on parallel coils that stack against each other under load.

While a скошенная спиральная пружина distributes stress evenly across angled coils, a compression spring experiences increasing stress as coils come into contact. This structural difference explains why a скошенная спиральная пружина performs better in high-cycle applications.

| Характеристика | Уплотнения со скошенными спиральными пружинами | Compression Spring |

|---|---|---|

| Геометрия катушки | Angled | Parallel |

| Распределение напряжений | Even | Concentrated |

| Coil Interaction | Independent | Coil stacking |

| Friction | Low | Высокий |

The structural advantages of a скошенная спиральная пружина directly result in superior mechanical and electrical performance.

One of the most important benefits of a скошенная спиральная пружина is its ability to maintain consistent force throughout compression. This makes the скошенная спиральная пружина ideal for applications requiring stable contact pressure.

Compression springs exhibit increasing force as deflection increases. In contrast, a скошенная спиральная пружина avoids excessive load buildup, protecting mating components and extending system life.

Because each coil in a скошенная спиральная пружина deflects independently, fatigue stress is significantly reduced. A скошенная спиральная пружина can withstand millions of cycles without significant performance degradation.

Compression springs experience coil friction and permanent deformation under repeated loads. In applications where long life is critical, a скошенная спиральная пружина is a far more reliable solution.

A скошенная спиральная пружина provides continuous conductive contact and uniform pressure, which is essential for effective EMI shielding. For this reason, the скошенная спиральная пружина is widely used in RF enclosures, connectors, and electronic housings.

Compression springs lack consistent electrical contact and are not designed for EMI shielding. In contrast, a скошенная спиральная пружина maintains electrical continuity even under vibration.

A скошенная спиральная пружина can be installed in various groove designs, including rectangular, dovetail, and circular grooves. This flexibility allows the скошенная спиральная пружина to accommodate misalignment and surface irregularities better than compression springs.

Common applications for a скошенная спиральная пружина включают:

In each case, the скошенная спиральная пружина outperforms traditional compression springs in reliability and service life.

Although a скошенная спиральная пружина has a higher initial cost, its long service life and reduced maintenance make it a cost-effective solution over time. For high-reliability systems, a скошенная спиральная пружина offers superior total cost of ownership.

Наш сайт скошенная спиральная пружина products are engineered for applications where consistent force, durability, and electrical conductivity are essential.

Key Features of Our Canted Coil Spring:

Each скошенная спиральная пружина is manufactured to strict quality standards to ensure repeatable and reliable performance.

The comparison of canted coil spring vs compression spring clearly demonstrates that a скошенная спиральная пружина delivers superior performance in load consistency, fatigue life, and EMI shielding capability. For engineers designing critical systems, selecting a скошенная спиральная пружина ensures long-term reliability and optimal performance.

FOR MORE INFO.,PLEASE EMAIL TO : sale01@handaspring.com