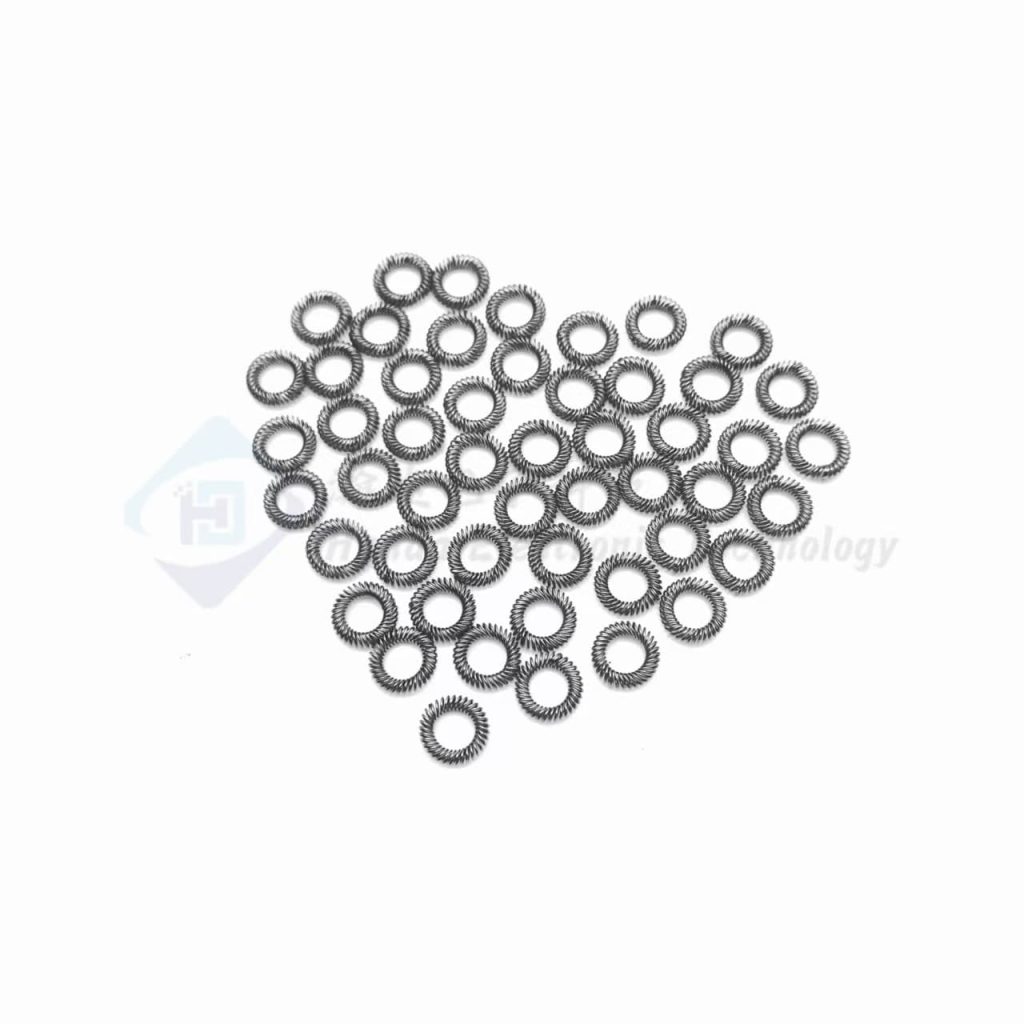

Canted Coil Spring Seals Übersicht

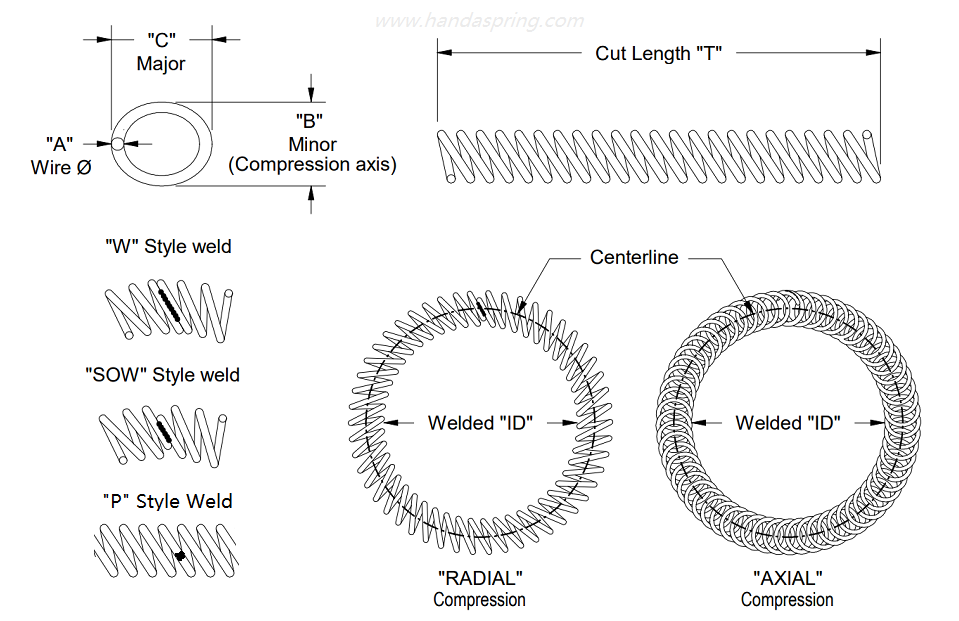

Kantige Spiralfedern auch bekannt als: Schrägspiralfeder, Drahtwickelfeder, gewickelte Feder, Schrägspirale.

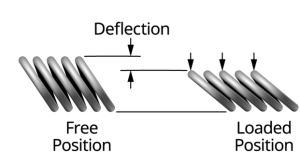

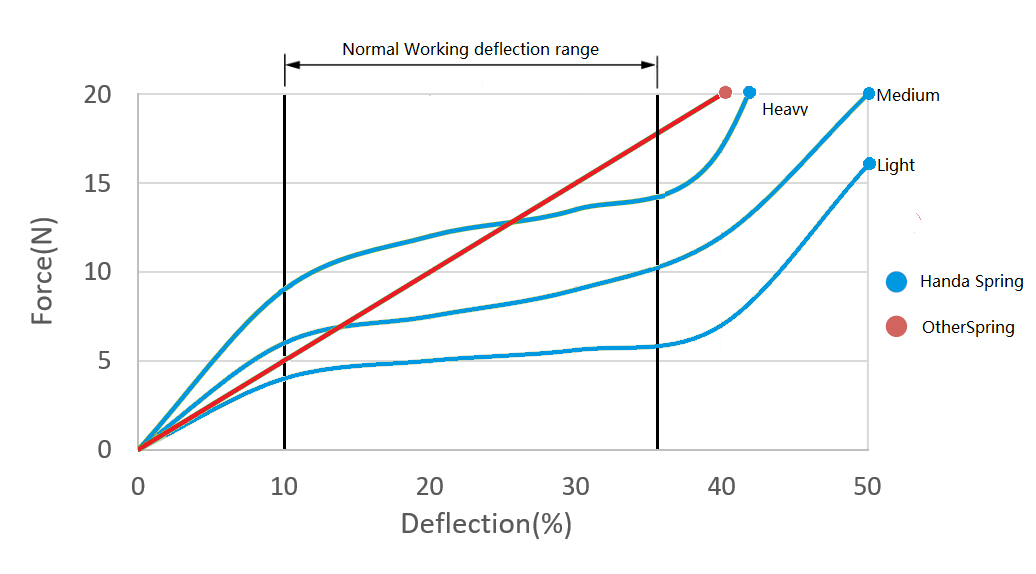

Handa-Energisatoren sind geneigte (oder schräge) Spiralfedern, die beim Zusammendrücken eine sehr flache Lastkurve erzeugen. Sie werden zur Erregung von Nutringdichtungen und anderen Bauteilen verwendet und bieten konstante, vorhersehbare Lasten über ihren großen Auslenkungsbereich. Die Slant Coil-Feder hat eine flache Kraft-Weg-Kurve, was bedeutet, dass die abgegebene Kraft über einen großen Wegbereich konstant bleibt. Diese Eigenschaft macht sie perfekt für Hochgeschwindigkeits-Drehsysteme oder Anwendungen, die eine genaue Kontrolle der Laufreibung oder des Ausbrechens erfordern. Sie kann auch in Geräten eingesetzt werden, die eine schnelle Trennung erfordern, wenn viele Einrast- und Ausrastzyklen erforderlich sind.

Kundenspezifische Größen und Materialien sind ebenfalls erhältlich.

Verfügbare Materialien und Beschichtungen sind:

Materialien: Rostfreier Stahl (z.B. 302, 316), Platin-Iridium, MP35N, Elgiloy®, Beryllium-Kupfer, Inconel®, Hastelloy® usw.,

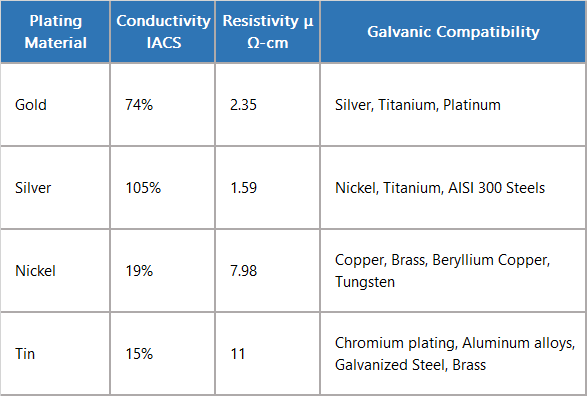

Beschichtung: Vergoldung, Versilberung, Verzinnung und Vernickelung möglich.

Für andere kundenspezifische Werkstoffe oder Beschichtungsoptionen, hier klicken Handa Spring zu kontaktieren.