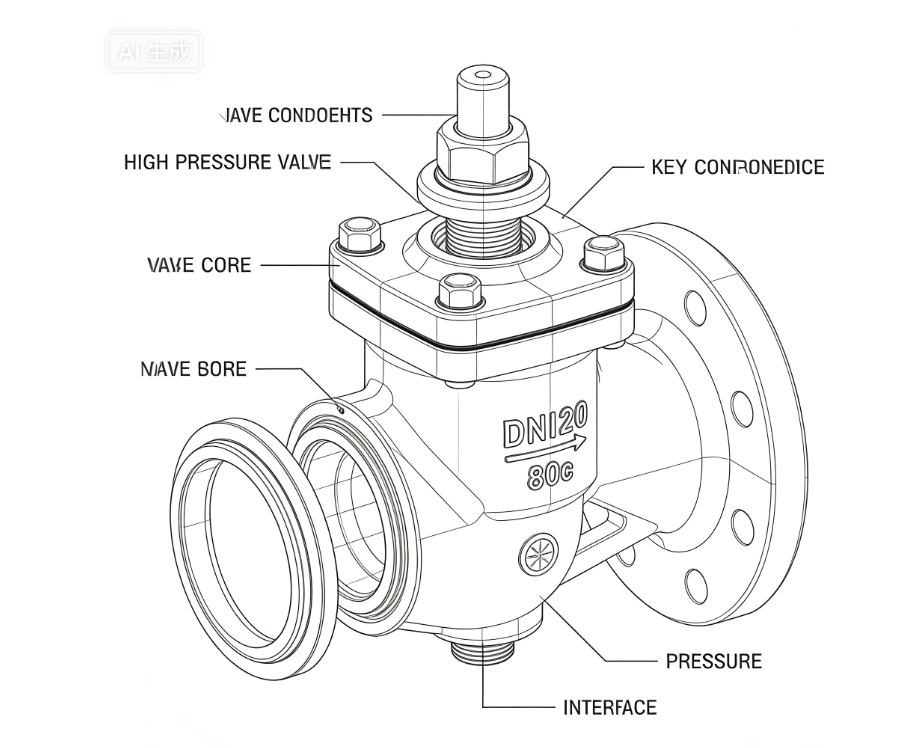

キャントコイルスプリングシールの概要

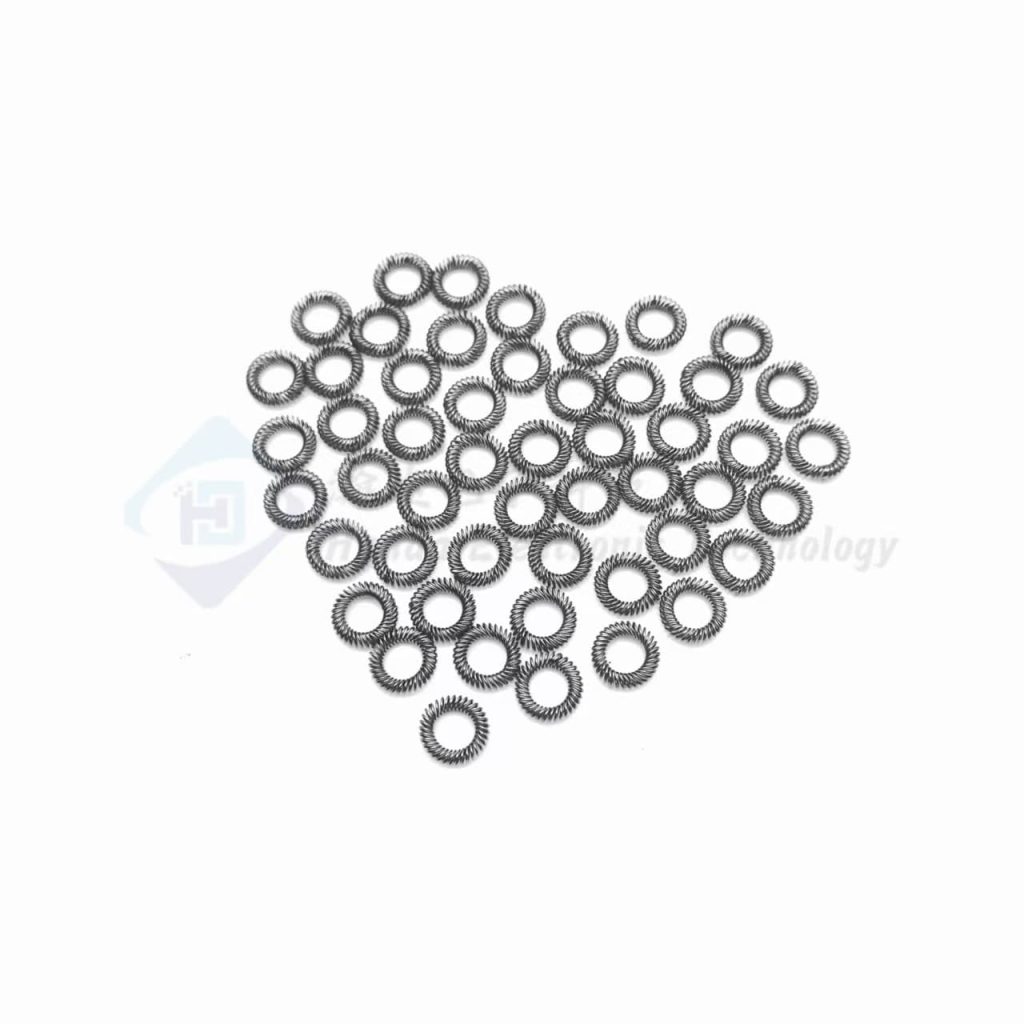

コイルスプリング also known as: Slant Coil Spring, Wire Wound Spring, Wound Spring, Slant Coil.

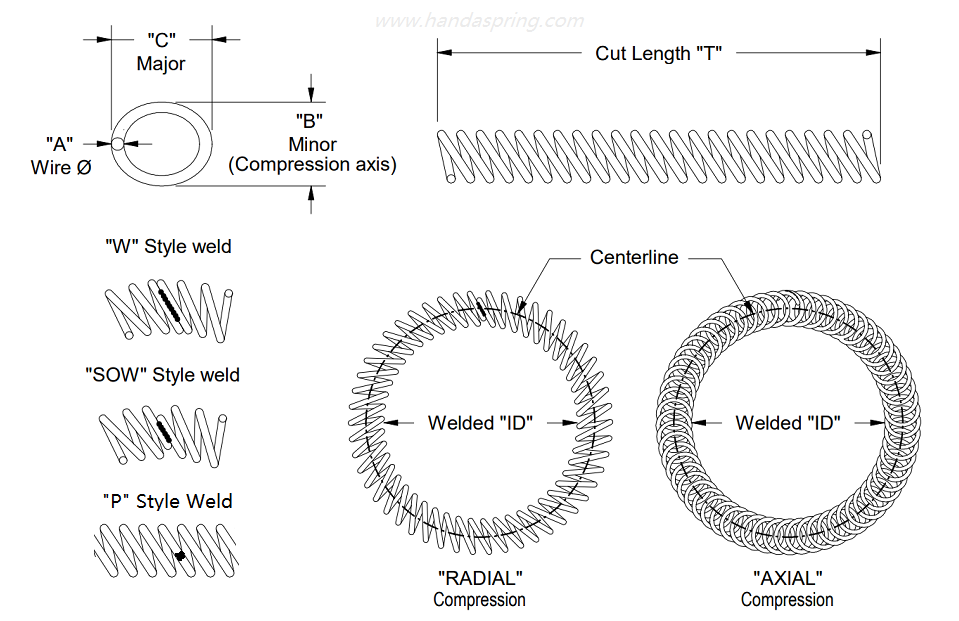

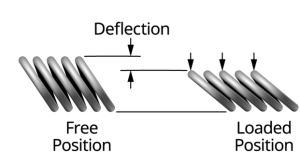

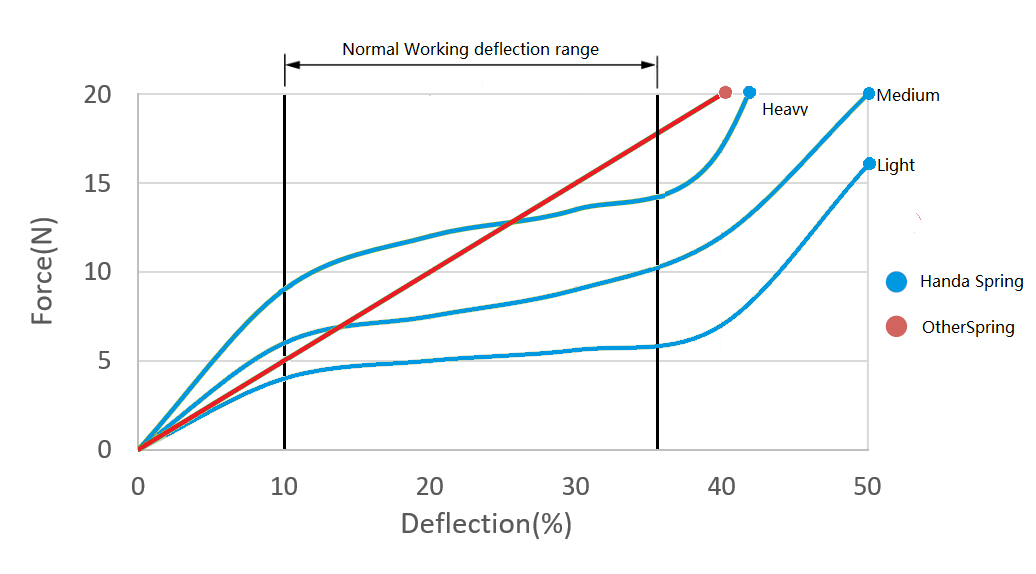

Handa energizers are Canted (or slanted) Coil springs that produce a very flat load curve when compressed. They are used to energize U-cup seals and other components providing constant predictable loads throughout their wide deflection range. The Slant Coil spring has a flat load to deflection curve which means that the force emitted stays constant over a wide deflection range. This feature makes it perfect for high-speed rotary systems or applications which require tight control of running friction or breakout. It may also be used within devices that require a quick disconnect where many engagement and disengagement cycles are necessary.

特注サイズ、特注素材も承ります。.

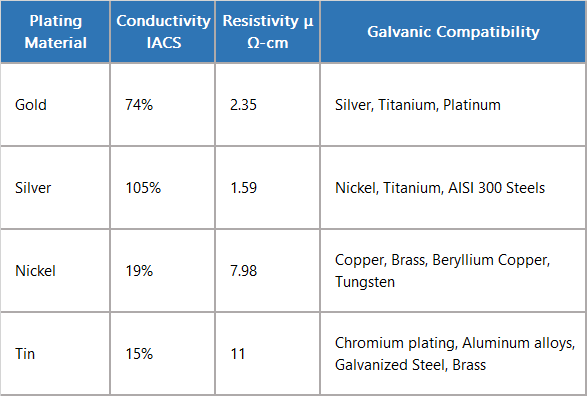

Materials And Plating available include:

Materials: Stainless steel (e.g., 302, 316), Platinum Iridium, MP35N, Elgiloy®, Beryllium copper, Inconel®, Hastelloy® etc.,

メッキ: Gold, Silver, Tin, and Nickel plating available.

For other custom meterials or plating options, click here to contact Handa Spring.