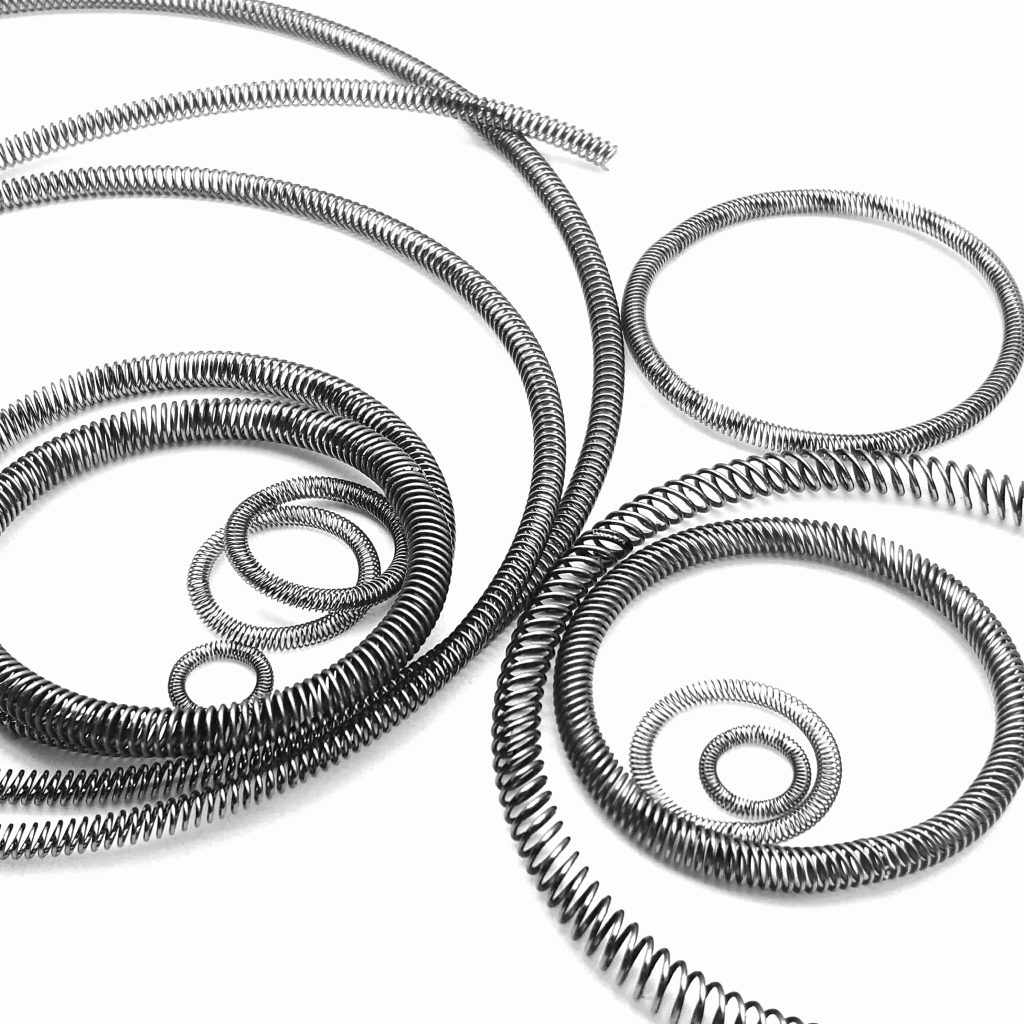

Пружины со скошенными витками для уплотнений с пружинным приводом

Пружины со скошенными виткамиПружины, также известные как пластинчатые пружины, играют важнейшую роль в различных областях применения уплотнений, предлагая уникальные конструктивные преимущества и выдающиеся эксплуатационные характеристики. Эти пружины являются неотъемлемой частью обеспечения эффективного уплотнения, особенно в динамичных средах, где надежность имеет первостепенное значение. В этой статье мы рассмотрим все тонкости пружин со скошенными витками, их конструкцию, материалы, рабочие характеристики, области применения, рекомендации по установке, производственные процессы и общие преимущества.

Определяющей характеристикой пружин с коническими витками является их наклонная конфигурация витков. Эта уникальная конструкция позволяет пружине обеспечивать равномерную упругую деформацию под нагрузкой, эффективно заполняя зазоры между уплотнительными поверхностями. Наклонное расположение витков обеспечивает постоянное усилие на выходе, что очень важно для обеспечения надежного уплотнения.

Пружины со скошенными витками обычно изготавливаются из высокоэффективных металлов, таких как:

Для улучшения характеристик пружины с коническими витками могут быть покрыты различными металлами, такими как золото или серебро. Такие покрытия улучшают электропроводность и коррозионную стойкость, делая пружины пригодными для специализированных применений.

Пружины со скошенными витками обладают несколькими ключевыми характеристиками, которые делают их очень эффективными в различных областях применения:

Конические пружины находят широкое применение в различных отраслях промышленности благодаря своей универсальности и производительности:

Пружины со скошенными витками широко используются в жидкостных уплотнениях, особенно в динамических системах с малым и средним давлением. Они обеспечивают эффективное уплотнение от жидкостей и газов, предотвращая утечку.

Эти пружины служат эффективными электрическими компонентами, особенно в приложениях, требующих сильной передачи тока в ограниченном пространстве, например, в электронных межсоединениях.

Пружины со скошенными витками обеспечивают превосходное экранирование электромагнитных помех (EMI), снижая уровень радиочастотных помех в военных и высокопроизводительных приложениях.

Они могут работать как механические соединители, обеспечивая блокировку, фиксацию и удержание механизмов в различных системах.

При разработке пружин со скошенными витками для конкретных применений следует учитывать несколько факторов:

Выбор подходящего диаметра пружины имеет решающее значение для обеспечения упругости и эффективности уплотнения в конкретной области применения.

Выбор правильного диаметра проволоки уравновешивает прочность и гибкость пружины, влияя на ее работу под нагрузкой.

Высота витков влияет на диапазон деформации пружины и ее грузоподъемность, что делает ее важным конструктивным параметром.

Угол наклона влияет на площадь контакта и распределение силы, что очень важно для эффективного уплотнения.

Количество витков в пружине влияет на ее упругость и несущую способность, что требует тщательного анализа конструкции.

Правильная установка очень важна для достижения максимальной эффективности пружин со скошенными витками. Вот некоторые ключевые моменты:

При установке необходимо соблюдать осторожность, чтобы не повредить уплотнительную кромку, так как это может привести к утечке масла или газа.

Регулярные проверки состояния уплотнений важны для предотвращения отказов уплотнений из-за старения или износа. Своевременная замена изношенных пружин поможет сохранить производительность.

Убедитесь, что сменные пружины соответствуют спецификациям оригинального оборудования, чтобы гарантировать эффективное уплотнение.

Пружины со скошенными витками обычно изготавливаются с использованием прецизионных технологий точения и формовки. Этот процесс обеспечивает точность и стабильность конечного продукта.

Хотя точение и формовка могут быть менее эффективными, чем другие методы производства, они позволяют получить высококачественные пружины, необходимые для надежного уплотнения.

Пружины со скошенными витками обладают рядом преимуществ, которые способствуют их широкому применению в различных отраслях промышленности:

Эти пружины сохраняют работоспособность в сложных условиях, включая вибрацию, ударные нагрузки и угловые отклонения, обеспечивая надежное уплотнение и электрические соединения.

Пружины со скошенными витками служат не только в качестве уплотнительных элементов, но и в качестве проводящих компонентов и решений для экранирования электромагнитных помех, что делает их пригодными для различных применений.

Пружины со скошенными витками отвечают требованиям к пространству, весу и мощности (SWaP), позволяя увеличить плотность контактов в меньшем пространстве и снизить общую сложность системы.

Гладкая поверхность пружин со скошенными витками упрощает очистку и стерилизацию, что делает их идеальными для использования в медицинской, фармацевтической, пищевой промышленности и производстве напитков.

Пружины со скошенными витками, обладающие уникальной конструкцией и превосходными эксплуатационными характеристиками, незаменимы во множестве приложений в различных отраслях промышленности. При выборе и установке этих пружин необходимо учитывать конкретные требования к применению и условия окружающей среды, чтобы обеспечить оптимальную эффективность уплотнения и работу устройства. Обращение к профессиональным производителям или поставщикам пружин может дать ценные сведения и индивидуальные решения, отвечающие вашим потребностям, обеспечивая наилучшие результаты для ваших приложений.