Canted Coil Springs for Spring Energized Seals

Canted coil springs, also known as slat coil springs, play a crucial role in various sealing applications, offering unique design advantages and outstanding performance characteristics. These springs are integral to ensuring effective sealing, particularly in dynamic environments where reliability is paramount. This article will delve into the intricate details of canted coil springs, covering their design, materials, performance features, applications, installation guidelines, manufacturing processes, and overall advantages.

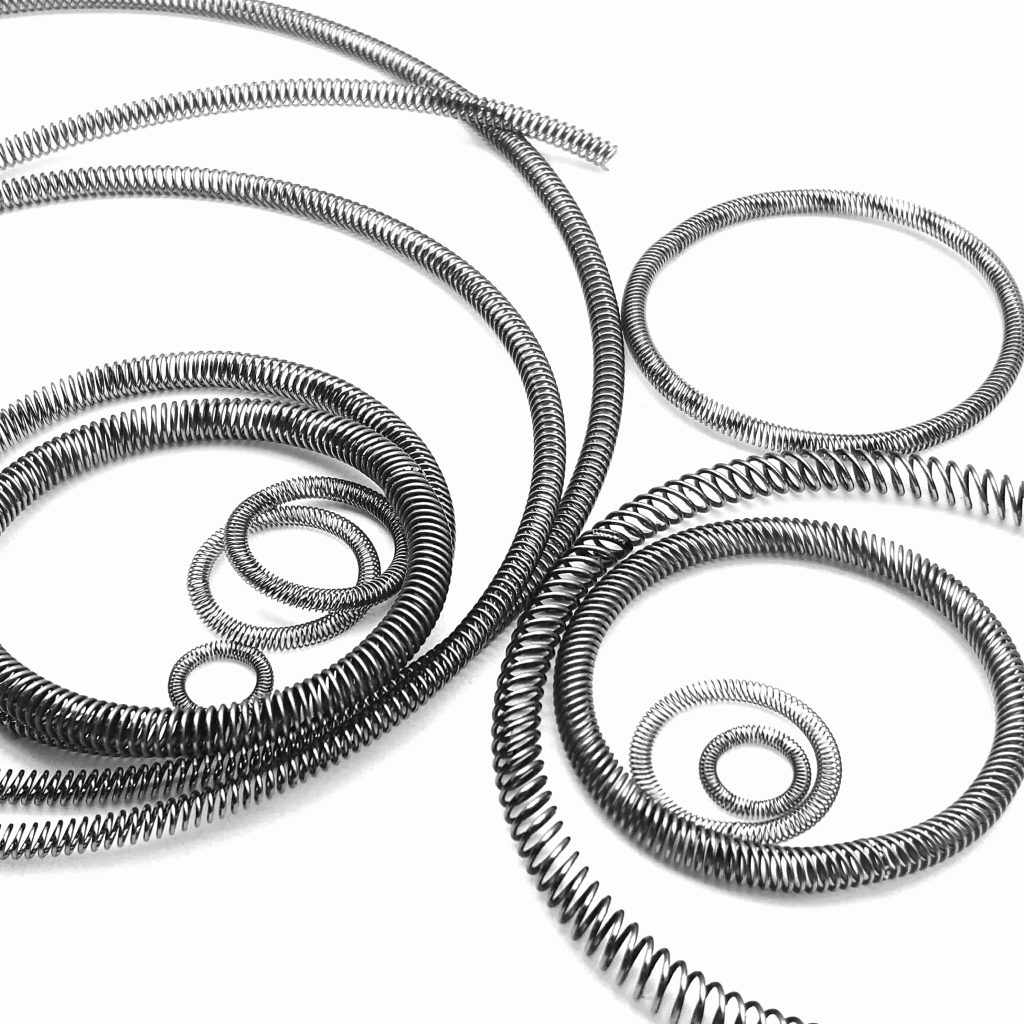

The defining characteristic of canted coil springs is their inclined coil configuration. This unique design enables the spring to provide uniform elastic deformation under load, effectively filling gaps between sealing surfaces. The inclined arrangement of the coils allows for a consistent force output, which is crucial in maintaining a reliable seal.

Canted coil springs are typically constructed from high-performance metals, such as:

To enhance performance, canted coil springs can be coated with various metals such as gold or silver. These coatings improve electrical conductivity and corrosion resistance, making the springs suitable for specialized applications.

Canted coil springs possess several key performance features that make them highly effective in various applications:

Canted coil springs find widespread use in various industries due to their versatility and performance:

Canted coil springs are commonly used in fluid seals, particularly in light to medium-pressure dynamic applications. They ensure effective sealing against liquids and gases, preventing leakage.

These springs serve as efficient electrical components, especially in applications requiring strong current transmission in confined spaces, such as electronic interconnect designs.

Canted coil springs provide excellent electromagnetic interference (EMI) shielding, reducing RF interference in military and high-performance applications.

They can function as mechanical connectors, enabling locking, latching, and holding mechanisms in various systems.

When designing canted coil springs for specific applications, several factors should be considered:

Choosing the appropriate spring diameter is crucial to ensure both elasticity and sealing effectiveness in the given application.

Selecting the right wire diameter balances the spring’s strength and flexibility, impacting its performance under load.

The height of the coils affects the spring’s deformation range and load capacity, making it an important design consideration.

The angle of inclination influences the contact area and force distribution, critical for effective sealing.

The number of turns in the spring affects its elasticity and load-bearing capacity, necessitating careful design analysis.

Proper installation is essential to maximize the performance of canted coil springs. Here are some key considerations:

Care should be taken during installation to prevent damage to the sealing lip, as this can lead to oil or gas leaks.

Routine checks on the sealing condition are important to prevent sealing failures due to aging or wear. Timely replacement of worn springs can help maintain performance.

Ensure that the replacement springs match the specifications of the original equipment to guarantee effective sealing.

Canted coil springs are typically manufactured using precision turning and forming techniques. This process ensures accuracy and consistency in the final product.

Although turning and forming can be less efficient than other manufacturing methods, it yields high-quality springs essential for reliable sealing performance.

Canted coil springs offer several advantages that contribute to their widespread use across various industries:

These springs maintain performance under challenging conditions, including vibration, shock loading, and angular deviations, providing dependable sealing and electrical connections.

Canted coil springs serve not only as sealing elements but also as conductive components and EMI shielding solutions, making them suitable for diverse applications.

Canted coil springs meet space, weight, and power (SWaP) requirements, enabling higher contact density in smaller spaces and reducing overall system complexity.

The smooth surface of canted coil springs simplifies cleaning and sterilization, making them ideal for use in the medical, pharmaceutical, food, and beverage industries.

Canted coil springs, with their unique design and superior performance, are indispensable in a multitude of applications across various industries. When selecting and installing these springs, it is essential to consider the specific requirements of the application and environmental conditions to ensure optimal sealing effectiveness and device performance. Engaging with professional spring manufacturers or suppliers can provide valuable insights and customized solutions tailored to your needs, ensuring the best possible outcomes for your applications.