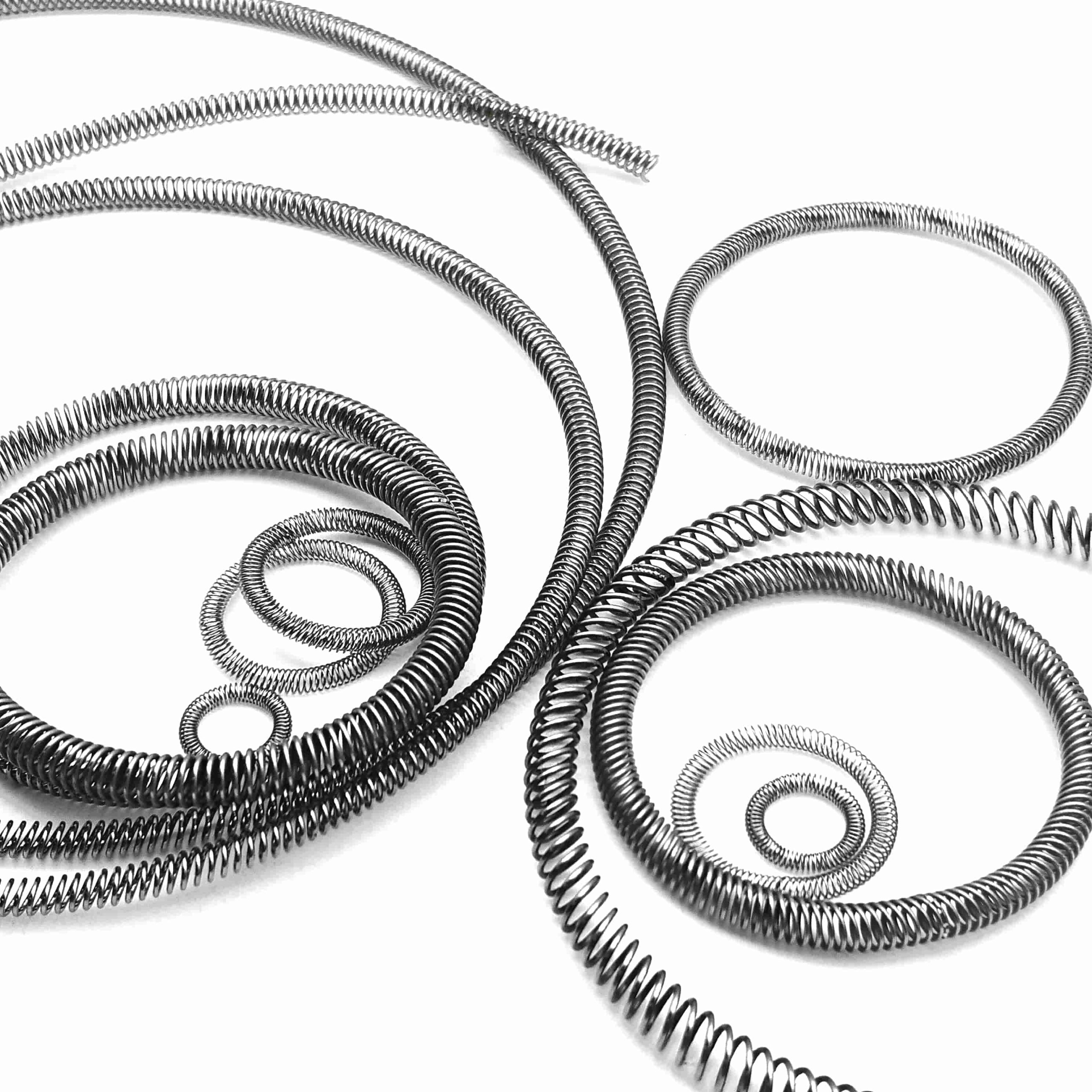

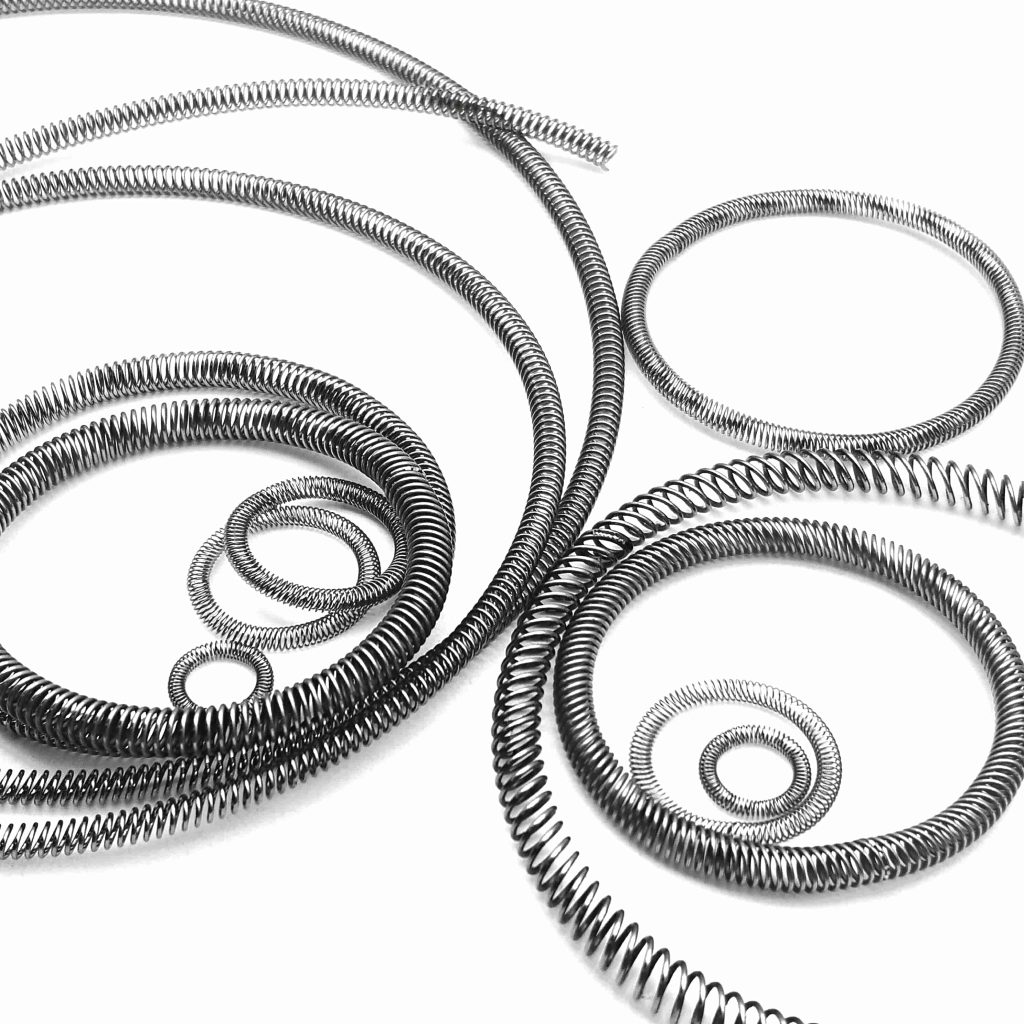

Canted coil seal springs

Canted coil seal springs, known for their unique design and exceptional sealing performance, are widely used in high-performance sealing applications. These springs, with their slanted coil arrangement, offer a reliable and stable sealing effect under various operating conditions. This article provides a detailed overview of canted coil seal springs in different diameters, covering their basic characteristics, features based on diameter size, material choices, installation methods, and application scenarios. By understanding the various diameter sizes and their specific uses, users can better select and apply the appropriate canted coil seal springs for diverse industrial needs.

Canted coil seal springs are specialized sealing components widely used in various industries for their reliability and effectiveness. These springs are characterized by a unique slanted coil design that allows them to adapt to uneven surfaces and provide stable sealing performance even under fluctuating pressures and temperatures. The size of the coil diameter plays a crucial role in determining the spring’s ability to handle specific loads, its response time, and its application in various sealing environments.

This article explores the differences in canted coil seal springs based on diameter, focusing on their unique features, benefits, and applications in different industrial sectors. The varying diameters of these springs allow for customization to meet different sealing demands, from small precision instruments to large-scale industrial equipment.

Before delving into the differences based on diameter, it is essential to understand the fundamental characteristics of canted coil seal springs.

Canted coil springs feature a unique slanted coil arrangement, which distinguishes them from conventional spring designs. This slanted configuration allows for uniform pressure distribution and ensures effective sealing, even when the sealing surfaces are not perfectly flat. The angle of the coils contributes to the spring’s ability to create a reliable seal under a wide range of pressure and temperature conditions.

Canted coil seal springs offer a high degree of flexibility, allowing them to adapt to a wide range of operating conditions. They can be compressed or expanded to suit specific sealing needs, ensuring that the correct pre-load is applied for optimal sealing performance.

By adjusting the diameter, height, width, and spacing of the coils, canted coil springs can be tailored to provide different load capacities. This makes them suitable for various applications, from light-duty to high-load sealing requirements.

Canted coil seal springs exhibit excellent thermal stability, allowing them to maintain their sealing effectiveness even in environments with fluctuating or extreme temperatures. This characteristic makes them suitable for applications in industries that require reliable sealing in high-temperature environments.

Canted coil seal springs are available in a wide range of diameters to meet specific application needs. Below is an analysis of the characteristics and applications of canted coil seal springs based on their diameter sizes.

The performance of canted coil seal springs depends heavily on the materials used. Several materials are commonly employed to manufacture these springs, each offering unique advantages for specific applications.

Stainless steel is a popular material choice due to its excellent corrosion resistance and mechanical strength. It is suitable for a wide range of applications, including those in harsh environments.

Elgiloy® is a high-performance alloy known for its outstanding corrosion resistance and elasticity. It is ideal for applications that require seals to perform under extreme conditions, such as high temperature or corrosive environments.

Hastelloy® is a nickel-based alloy that excels in high-temperature and corrosive environments. It is often used in industries such as aerospace, petrochemical, and chemical processing where both high temperature and corrosion resistance are critical.

Inconel® is another nickel-based alloy that offers excellent resistance to high temperatures and pressure. It is often used in high-performance applications in extreme environments, such as aerospace and power generation.

HYNOX® is a high-performance alloy known for its resistance to corrosion and elasticity. It is suitable for specialized sealing applications where standard materials may not provide the necessary performance.

Proper installation and maintenance of canted coil seal springs are essential for ensuring their long-term effectiveness. Below are some key considerations for installing and maintaining these springs:

Before installing the canted coil seal spring, it is crucial to ensure that the shaft surface is clean and free of dust or debris. Contaminants can impair the sealing performance, leading to premature failure.

During installation, the seal should be aligned with the centerline of the shaft to prevent eccentric wear and extend the lifespan of the spring.

When installing the spring, it is important to apply uniform pressure to prevent damage to the spring or seal lip. This ensures that the spring operates optimally without compromising its sealing capabilities.

Using specialized tools during installation can help ensure the spring is placed correctly without damaging the components. These tools are designed to assist in maintaining the correct positioning and alignment.

Regular inspection of the seal is essential to detect wear, aging, or damage. Timely replacement of worn-out seals ensures continued sealing performance and prevents equipment failure.

Canted coil seal springs offer a versatile and reliable sealing solution for a wide range of industrial applications. By understanding the specific characteristics and applications of springs in different diameters, users can make informed decisions to ensure optimal performance in their sealing systems. The selection of appropriate materials and proper installation techniques further contribute to the longevity and reliability of these sealing components. Canted coil seal springs remain a crucial element in high-performance sealing systems, providing long-lasting, stable performance across various industries.