Cantilever springs, integral to many mechanical systems, come in various shapes and designs, each suited to specific applications. Among these, U-shaped and V-shaped cantilever springs stand out for their distinct characteristics and performance profiles. Understanding these differences is crucial for selecting the appropriate spring type for various applications, particularly in sealing environments where consistent pressure and reliability are essential.

Cantilever springs are mechanical devices that store energy and exert a force when deflected. They are widely used in applications ranging from automotive to aerospace and industrial machinery. The primary function of these springs is to provide support, absorb shock, and maintain tension, ensuring the proper functioning of various mechanical systems.

The design of a cantilever spring significantly influences its performance, including its load-bearing capacity, deflection characteristics, and fatigue life. Among the many designs, U-shaped and V-shaped cantilever springs are particularly noteworthy due to their unique structural properties.

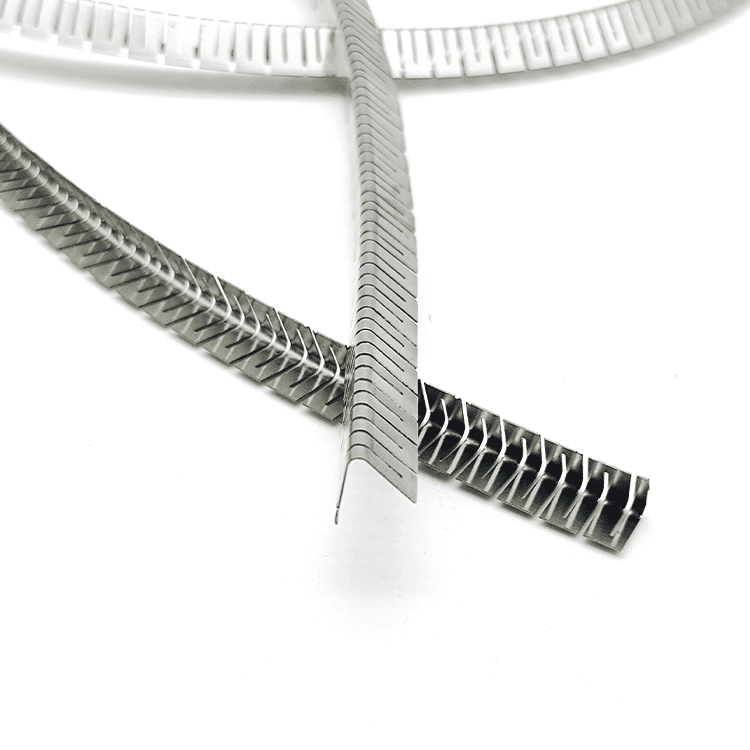

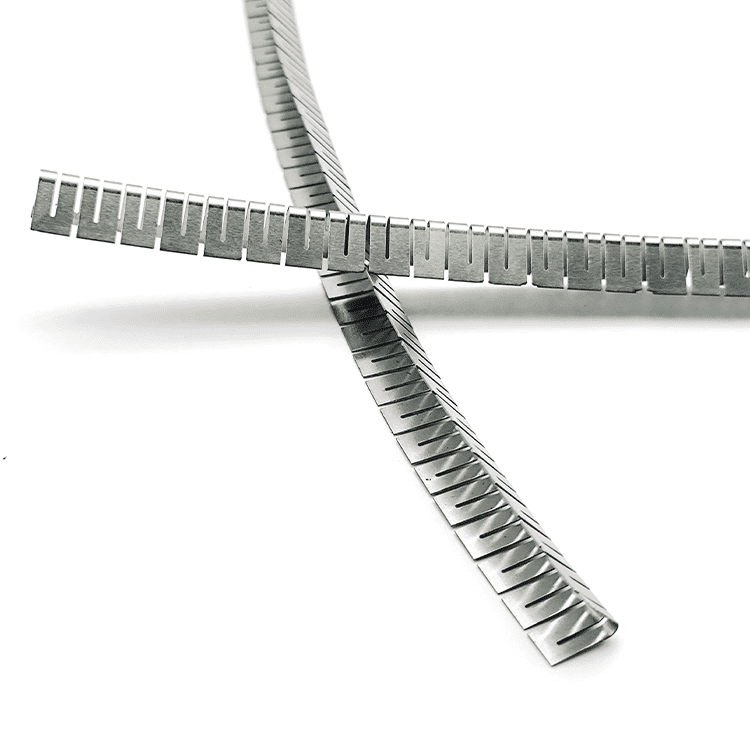

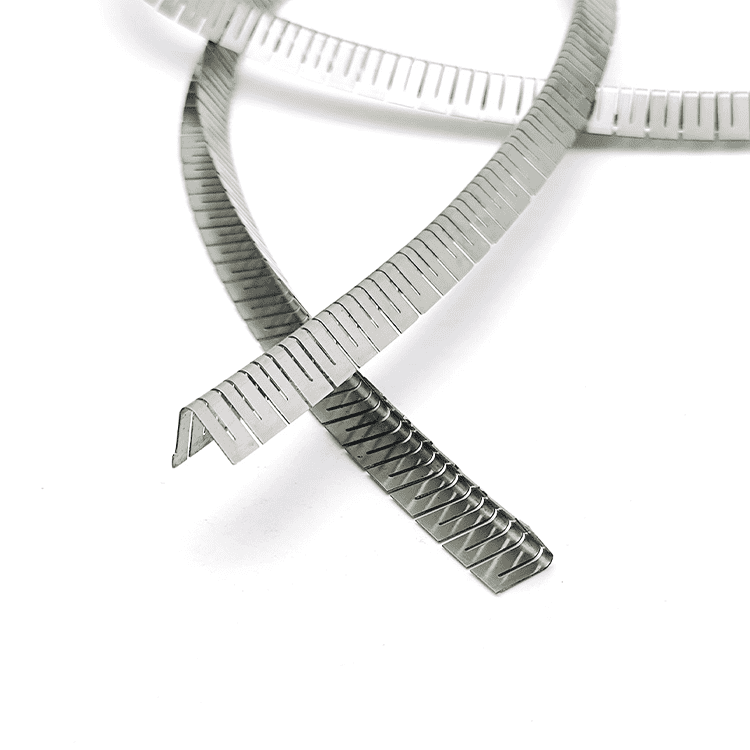

U-shaped cantilever springs are characterized by their open U-shape, which allows for even distribution of radial pressure. This design is specifically tailored to applications where stable contact pressure is essential. The uniform shape provides consistent force across the contact area, making it suitable for various sealing environments.

U-shaped cantilever springs find applications in environments where balanced pressure distribution is critical. Some typical use cases include:

V-shaped cantilever springs, named for their distinctive V shape, are designed to provide a significant initial force when compressed. This design makes them suitable for applications that require rapid response times or high starting pressures.

V-shaped cantilever springs excel in environments where quick sealing response and efficient operation are paramount. Typical applications include:

The choice between U-shaped and V-shaped cantilever springs largely depends on the specific requirements of the application. Here, we compare the two based on various factors:

The choice between U-shaped and V-shaped cantilever springs is determined by the specific requirements of the application, including pressure conditions, motion types, working environments, and sealing characteristics. U-shaped springs are preferable for stable, long-term sealing in high-pressure environments, while V-shaped springs excel in dynamic applications requiring rapid response and adaptability.

By understanding the unique features and advantages of each spring type, engineers and designers can optimize the performance of their systems, ensuring reliability and efficiency in various mechanical applications. The ongoing evolution in spring design and materials science promises further enhancements in performance, enabling even greater versatility in the use of cantilever springs across a broad spectrum of industries.

In summary, whether selecting a U-shaped or V-shaped cantilever spring, careful consideration of application-specific needs will lead to improved sealing performance and overall system reliability.