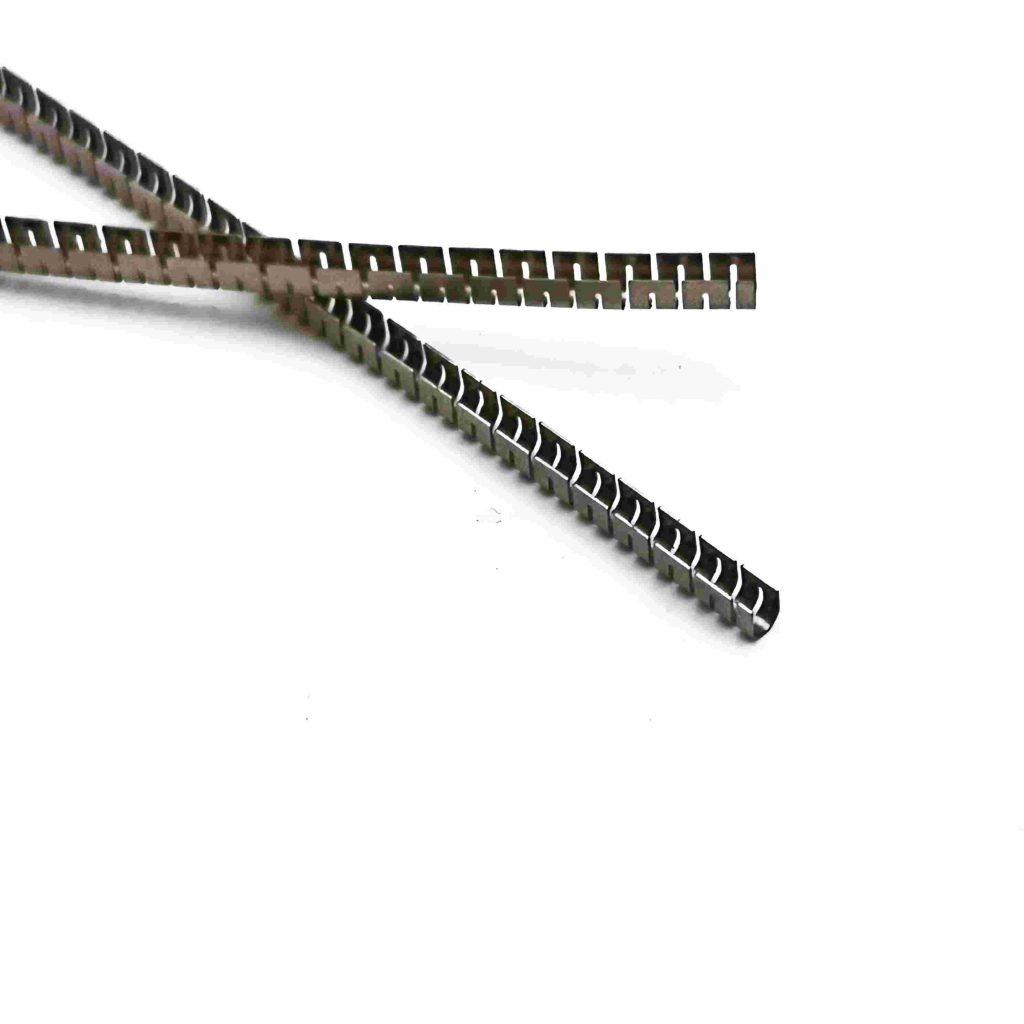

Cantilever U springs are a critical component in numerous mechanical systems, known for their versatility and adaptability in providing both mechanical force and flexibility in various applications. These springs are widely used across many industries due to their unique structure, which allows them to provide controlled deflection, tension, and support.

Cantilever U springs-Zhuoyue Spring

Cantilever U springs, also referred to as U-shaped cantilever springs, are a type of mechanical spring that typically features a U-shaped design. The structure allows them to deflect under load, offering both support and flexibility to the system they are used in. These springs are typically characterized by their ability to absorb shocks, resist vibrations, and return to their original shape after deflection.

The unique cantilevered design ensures that these springs can handle lateral forces while providing uniform distribution of force along their length. Cantilever U springs are used in various industries, including automotive, aerospace, electronics, and industrial machinery.

One of the primary features of cantilever U springs is their ability to provide controlled deflection under load. The U-shape helps distribute forces evenly across the spring, ensuring consistent performance even in challenging conditions.

Cantilever U springs offer high elasticity, meaning they can absorb significant energy and return to their original shape after being deformed. This feature makes them particularly useful in applications where shock absorption and vibration dampening are crucial.

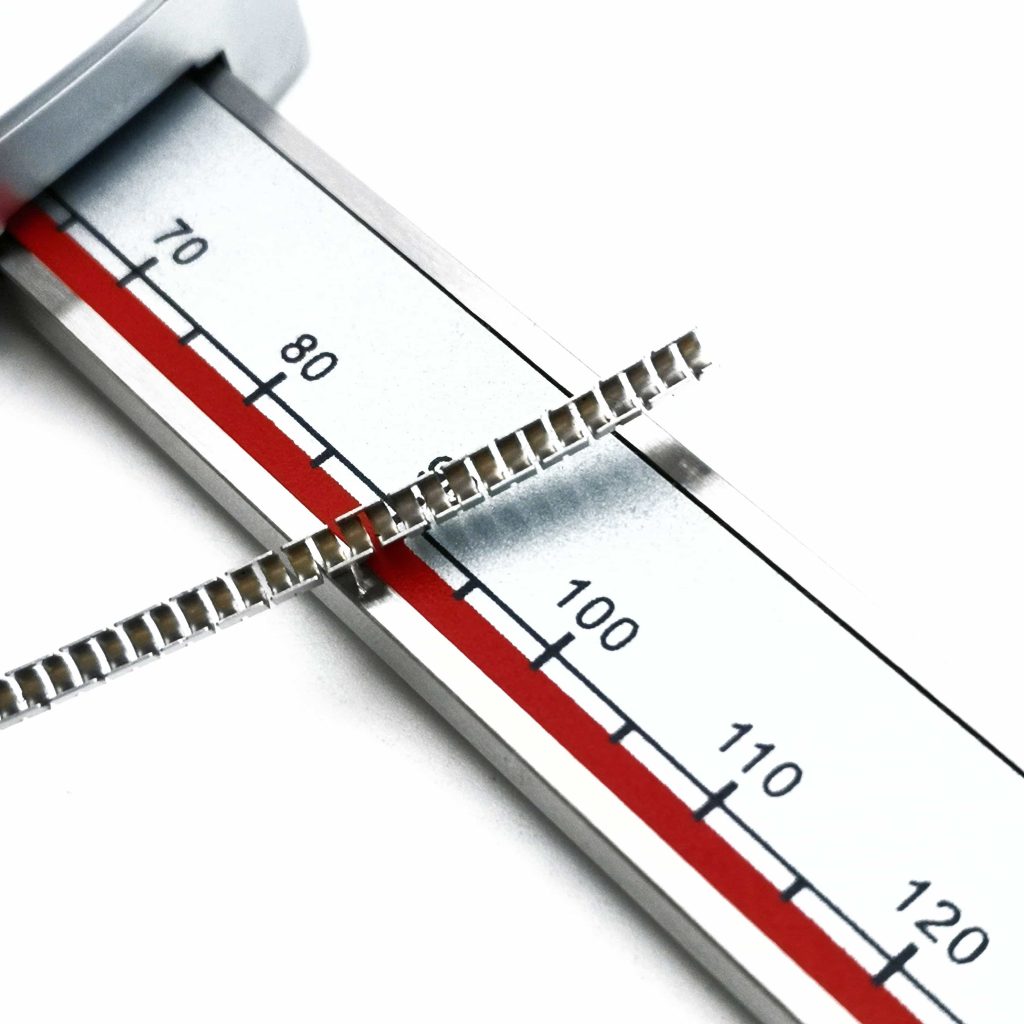

The compact and versatile design of cantilever U springs allows them to fit into tight spaces without sacrificing performance. This makes them ideal for applications where space is limited but reliable performance is essential.

Thanks to their robust construction and the use of high-quality materials, cantilever U springs can withstand continuous stress and fatigue, offering a long service life. Their ability to endure repeated cycles without failure is one of the reasons why they are a go-to solution for many industries.

Manufacturers can tailor cantilever U springs to specific customer needs. By adjusting the material, dimensions, and load characteristics, the spring can be optimized for different applications, making them highly versatile.

The standard U-shaped cantilever spring is the most common variation, offering a symmetrical structure that allows it to handle loads from both sides. This design is often used in applications where a balanced force distribution is needed.

This variation features a one-sided design, where the spring extends from a single fixed point. It is ideal for applications requiring unidirectional force or limited space.

Some cantilever U springs are designed with variable stiffness along their length, allowing for customized force distribution. This variation is used in systems where a gradual or uneven application of force is necessary.

In high-load applications, multiple layers of cantilever U springs may be stacked together. This multi-layered design enhances the spring’s ability to handle increased loads while maintaining flexibility.

The choice of material plays a crucial role in determining the performance and durability of cantilever U springs. Different materials offer distinct advantages depending on the application requirements.

Stainless steel is one of the most commonly used materials for cantilever U springs due to its excellent corrosion resistance, durability, and strength. It is ideal for applications where the spring will be exposed to harsh environments, such as in marine or outdoor equipment.

Phosphor bronze is another popular material, especially in electronics and telecommunications. It offers excellent electrical conductivity while providing sufficient strength and flexibility.

For applications that require a balance between cost-efficiency and performance, carbon steel is often used. Although it is prone to corrosion if not properly treated, carbon steel springs are strong and can be coated with protective layers to enhance their resistance to environmental factors.

Copper beryllium springs are chosen for their electrical conductivity and fatigue resistance. These springs are commonly used in electronic contacts and signal transmission applications.

For applications that require resistance to extreme environments, Elgiloy, a nickel-cobalt-chromium alloy, is an ideal choice. It provides exceptional resistance to corrosion, fatigue, and high temperatures, making it suitable for aerospace and chemical processing industries.

Cantilever U springs are used in a wide range of industries due to their flexibility, durability, and adaptability. Here are some of the most common applications:

In the automotive sector, they are commonly used in suspension systems, brake systems, and clutch mechanisms. They help absorb shocks and reduce vibrations, providing a smoother ride and better vehicle control.

In aerospace applications, cantilever springs are used in landing gear systems, control surfaces, and actuators. These springs are valued for their ability to withstand extreme forces, vibrations, and high-stress environments.

In the medical industry, cantilever U springs are found in devices such as surgical instruments, catheters, and diagnostic equipment. Their ability to provide precise control, flexibility, and reliability makes them crucial in life-saving technologies.

In industrial machinery, cantilever U springs are utilized in valve actuators, robotic systems, and pneumatic devices. They provide the necessary force and flexibility to ensure the smooth operation of machines in manufacturing and production environments.

In electronics, cantilever springs are often used in battery contacts, switches, and connectors. They provide reliable electrical contact while maintaining mechanical flexibility, making them an essential component in consumer electronics and telecommunications equipment.

Cantilever U springs are widely used in construction equipment such as cranes, excavators, and loaders. Their ability to handle heavy loads and absorb shocks makes them ideal for demanding construction applications.

One of the biggest advantages of cantilever springs is their versatility. They can be customized to fit a wide range of applications, from automotive suspensions to medical devices. Their adaptability in terms of load-bearing capacity, deflection, and material makes them suitable for numerous industries.

Cantilever U springs are known for their high strength-to-weight ratio, which is especially beneficial in applications such as aerospace and automotive systems. They can provide the necessary force and flexibility without adding significant weight to the overall structure.

One of the primary roles of cantilever U springs is to absorb shocks and dampen vibrations. This feature is critical in automotive and industrial machinery, where constant vibrations and impacts can reduce the life span of equipment and cause malfunctions.

U springs offer a cost-effective solution for many applications. Their ability to be mass-produced using standard materials makes them an affordable option without sacrificing performance.

Made from high-quality materials such as stainless steel or phosphor bronze, these springs are built to last. They can endure extreme conditions, such as high temperatures, heavy loads, and continuous deflection, without losing their effectiveness.

When designing U springs, it’s essential to consider the load requirements. The spring’s dimensions, material, and coil design should be adjusted to provide the necessary force and deflection.

The environment in which the spring will be used should dictate the choice of materials. For example, stainless steel or Elgiloy should be used in corrosive environments, while phosphor bronze is better suited for applications requiring electrical conductivity.

The available space in the application must be taken into account when designing these springs. The spring should be compact enough to fit within the allocated area without compromising its performance.

Cantilever U springs may be exposed to extreme temperatures, particularly in aerospace or automotive applications. The materials used in the spring should be chosen based on their ability to withstand high or low temperatures without losing their mechanical properties.

Cantilever U springs play an integral role in numerous industries due to their flexibility, adaptability, and resilience. Their ability to provide controlled deflection, absorb shocks, and endure extreme environmental conditions makes them a valuable component in many mechanical systems. By understanding their design, materials, and applications, industries can optimize their use to enhance performance, safety, and durability.

Whether in automotive, aerospace, electronics, or industrial machinery, cantilever U springs offer a cost-effective, durable solution that can be tailored to meet the specific needs of each application. With proper customization and material selection, these springs can provide long-lasting performance in even the most demanding environments.