Cantilever V-seal springs, also referred to as Cantilever V-shaped springs or Cantilever V-ring seals, are a specialized type of spring commonly used in sealing applications. These springs feature a unique cantilevered, V-shaped design that allows them to maintain consistent sealing performance in dynamic and static applications. Cantilever V-seal springs are widely used in various industries due to their high adaptability, longevity, and superior sealing performance in harsh environments.

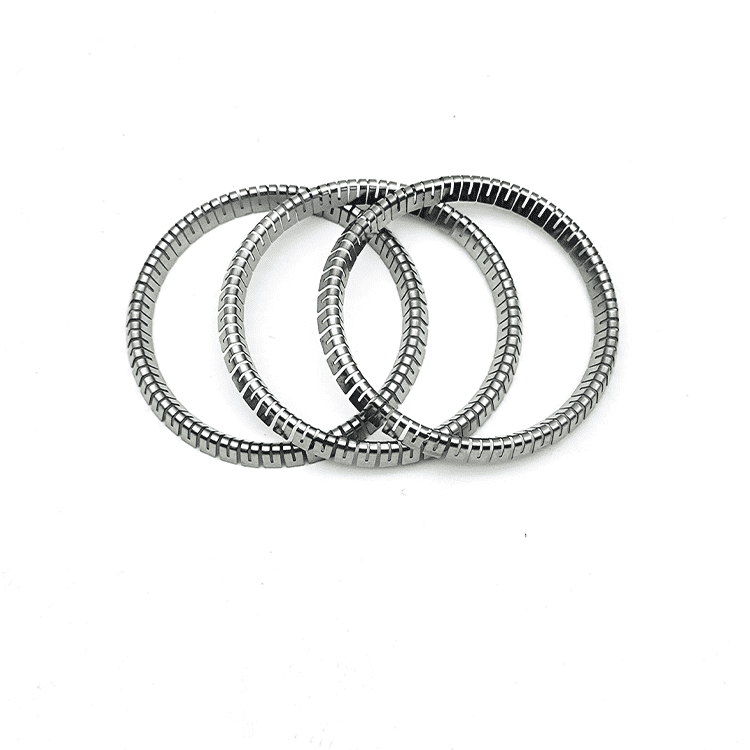

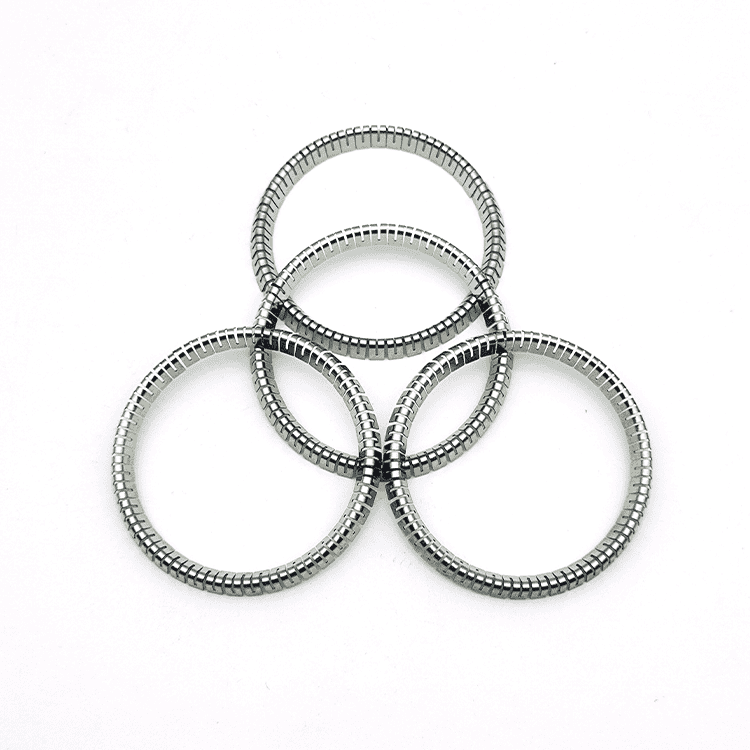

Cantilever V-seal springs

The distinctive feature of Cantilever V-seal springs lies in their “V” shape, which consists of a cantilevered spring with outward-facing arms that form the “V” configuration. These arms offer a high degree of flexibility and create an effective seal that conforms to mating surfaces. When pressure is applied to the spring, the arms compress, generating force that keeps the seal intact.

Cantilever V-seal springs function by maintaining a constant radial force against the sealing surface. As pressure or temperature fluctuates, the cantilevered arms compress or expand, creating an adaptive seal that can cope with varying environmental factors. The V-shaped arms provide flexibility to adjust to surface irregularities, ensuring a reliable seal without the need for frequent recalibration or maintenance.

Key factors include:

The material choice for Cantilever V-seal springs is critical for ensuring longevity and performance in specific operating conditions. Various metals and alloys are used depending on the requirements of the application.

Cantilever V-seal springs offer numerous advantages that make them preferable over traditional sealing methods in many industries:

Cantilever V-seal springs are used across a variety of industries due to their ability to maintain sealing effectiveness in both static and dynamic applications. These springs are particularly valuable in high-stakes environments where failure of the seal could lead to catastrophic outcomes.

Cantilever V-seal springs are used in aircraft engines, landing gear, and hydraulic systems where temperature, pressure, and vibration fluctuate constantly. Their ability to provide reliable sealing in such harsh environments makes them an essential component for ensuring aircraft safety and performance.

In the automotive sector, these springs are commonly used in fuel injection systems, transmission components, and exhaust systems. They help maintain a leak-proof seal in systems that experience rapid changes in pressure and temperature, improving vehicle efficiency and performance.

The oil and gas industry requires sealing solutions that can withstand corrosive chemicals, high pressures, and extreme temperatures. Cantilever V-seal springs are used in drilling equipment, pipelines, and valves to prevent leaks and protect equipment from environmental damage.

Medical devices such as pumps, valves, and diagnostic equipment rely on Cantilever V-seal springs for precision sealing in sterile environments. These springs are ideal for use in medical applications where reliability and longevity are paramount.

In renewable energy systems like wind turbines and solar power installations, Cantilever V-seal springs help to protect sensitive components from environmental contaminants such as dust, moisture, and salt spray, ensuring the long-term efficiency of the system.

In industrial manufacturing processes, these springs are used in machinery, robotics, and other automated systems to maintain efficient operation by preventing contamination and ensuring proper sealing of moving parts.

The installation of Cantilever V-seal springs requires precision to ensure that the spring performs effectively. Correct installation helps to maximize the life of the spring and the effectiveness of the seal.

Regular inspections of the spring and the sealing surface are crucial to ensuring long-term performance. Over time, springs can experience wear, particularly in dynamic applications. Checking for signs of fatigue, corrosion, or wear will help to identify potential issues before they lead to seal failure.

Manufacturers often offer custom design options to tailor Cantilever V-seal springs to specific applications. The design of the spring, including the material choice, size, and cross-sectional shape, can be modified to meet the unique requirements of different industries.

Cantilever V-seal springs represent a reliable and versatile solution for demanding sealing applications. Their unique V-shaped design and cantilevered arms provide exceptional sealing performance across a wide range of industries, from aerospace and automotive to medical and industrial manufacturing. With the ability to withstand extreme temperatures, high pressures, and harsh environmental conditions, Cantilever V-seal springs ensure long-lasting, efficient sealing in critical applications. As industries continue to advance and evolve, the adaptability and performance of Cantilever V-seal springs will make them an integral component in high-performance systems.