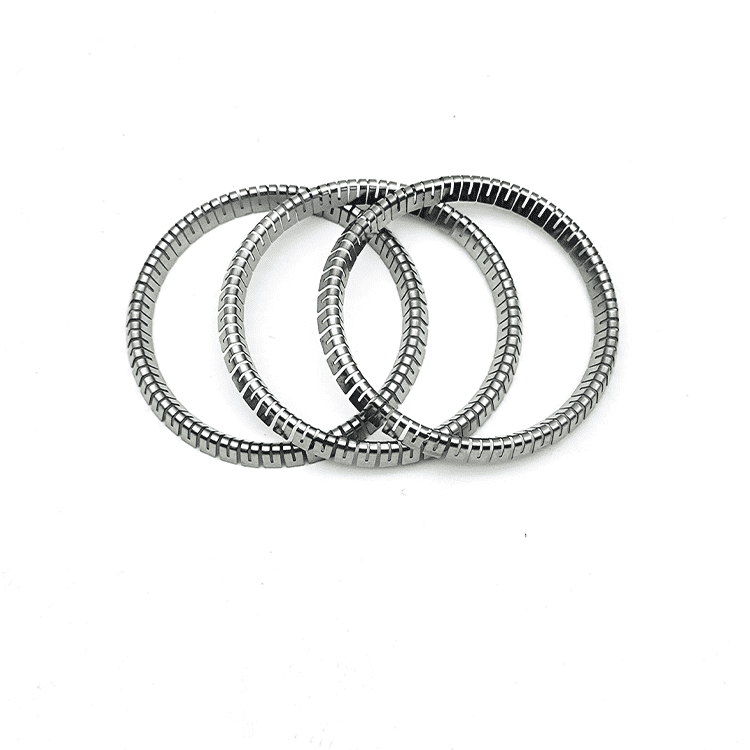

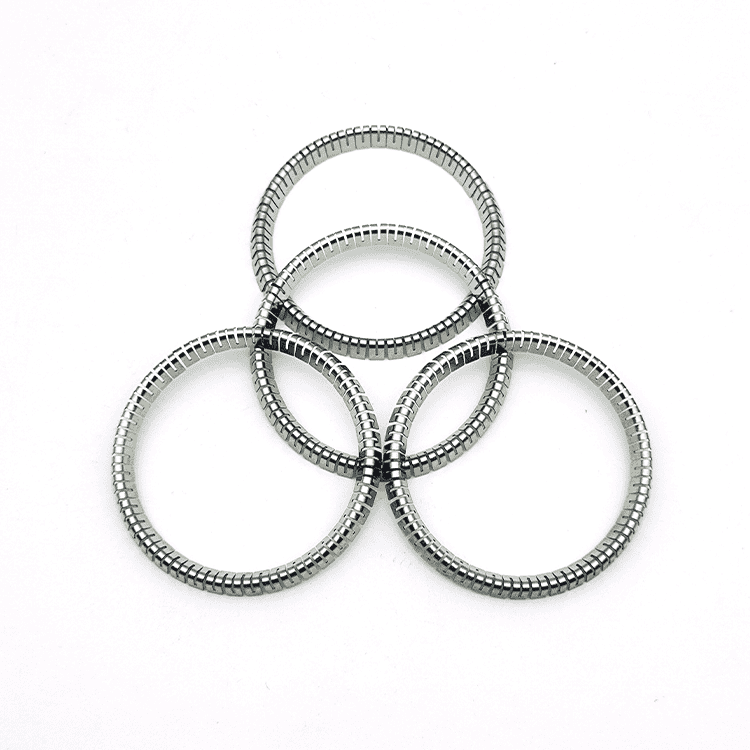

Cantilever V springs, also known as V-springs or finger springs, are a widely used solution in various sealing applications due to their unique construction, material versatility, and adaptability to harsh environments. These springs consist of a V-shaped metal spring embedded within a polymer jacket, which provides sealing energy through compression. This design offers numerous advantages over traditional sealing methods, making Cantilever V springs a preferred choice for dynamic and demanding applications.

Cantilever V Springs

Cantilever V springs stand out because of their excellent mechanical and sealing properties. Their key features provide significant performance advantages, especially in applications where traditional rubber seals and O-rings might fail.

The Cantilever V spring offers a linear load curve, meaning the load force increases steadily with deflection. This provides a controlled sealing response, which is beneficial in applications requiring precise force distribution. The spring’s deflection range allows it to accommodate misalignment and wear over time without losing its sealing integrity. This adaptability is a key advantage over more rigid seals that may degrade quickly in such conditions.

Unlike some sealing solutions where performance degrades rapidly as the material wears, Cantilever V springs are designed to reduce force as the seal wears down, helping maintain its functionality. This self-adjusting feature makes them ideal for dynamic applications where the seal is subjected to continuous motion, ensuring long-lasting performance.

Cantilever V springs are incredibly versatile and can be used in various applications where traditional seals, such as rubber U-cups or O-rings, might fail. They provide a superior alternative for industries requiring durable, wear-resistant sealing solutions.

The unique design of Cantilever V springs makes them perfect for reciprocating motions and environments involving mechanical shocks. The spring’s energy helps absorb movement and dampen vibrations, making it an excellent choice for applications like hydraulic cylinders and compressors.

Cantilever V springs are effective at acting as environmental excluders, preventing contaminants, dirt, and debris from entering the seal system. In addition, they are also capable of scraping viscous media, such as grease, oil, or slurry, ensuring that the seal remains clean and functional in harsh environments.

The success of Cantilever V springs in a range of demanding applications is due in part to their thoughtful construction and the high-performance materials used in their design.

The core of a Cantilever V spring is the V-shaped metal spring, which provides the mechanical force needed to energize the seal. This spring is embedded within a polymer jacket, which protects it from external factors such as chemicals, heat, or mechanical wear.

Cantilever V springs are available in a variety of spring materials, each suited to different operating conditions:

The polymer jacket that houses the V-shaped spring can also be customized with different materials based on the operating environment:

Cantilever V springs are highly versatile and find applications across various industries, thanks to their ability to maintain sealing performance under extreme conditions. Some of the most common applications include:

Cantilever V springs are commonly used in hydraulic cylinder applications, where they help maintain the integrity of the seal despite the high pressures and reciprocating motions involved. Their durability and flexibility make them an ideal choice for both mobile and stationary hydraulic systems.

These springs provide excellent sealing solutions for pumps and compressors, particularly in environments where viscous fluids are involved. Their ability to scrape media and exclude contaminants makes them valuable for maintaining equipment efficiency and longevity.

Cantilever V springs are specifically designed to handle reciprocating motions effectively. Their linear load curve and deflection range help them maintain a tight seal without excessive wear, making them suitable for applications involving reciprocating rods in industrial and mechanical systems.

For applications involving viscous fluids, such as in oil and gas industries, Cantilever V springs provide an effective sealing solution. Their ability to scrape viscous media while maintaining sealing integrity ensures that systems operate smoothly without leakage or contamination.

Cantilever V springs offer several key performance benefits that make them a superior sealing option for a range of demanding applications.

One of the primary advantages of Cantilever V springs is their wide temperature operating range. These springs can function in temperatures as low as -320°F (-195°C) and as high as 450°F (230°C), depending on the specific materials used in their construction. This makes them suitable for extreme environments, from cryogenic conditions to high-temperature industrial processes.

Cantilever V springs can handle a wide range of pressure ratings based on their design and material selection. Custom configurations can be created to meet specific pressure requirements for hydraulic, pneumatic, and other industrial systems.

Cantilever V springs are ideal for applications where wide tolerances or misaligned glands are present. Their flexible design allows them to adapt to these conditions without losing sealing effectiveness, making them suitable for applications with less precise manufacturing or assembly.

Zhuoyue Spring provides extensive manufacturing capabilities for Cantilever V springs. Our focus on quality and customization ensures that we can meet the diverse needs of our customers across various industries.

Cantilever V springs are available in continuous lengths from 100 ft. to annual quantities exceeding 100,000 ft. Whether you need short runs or large-scale production, our team can accommodate your requirements.

For specific projects, we offer pre-cut and welded Cantilever V springs. These are cut to the exact dimensions needed for your application, ensuring that installation is quick and easy. Additionally, our welded options ensure seamless splicing for continuous sealing performance.

If your project requires non-standard geometries, we offer custom tooling to create Cantilever V springs that perfectly fit your unique design. Our engineering team works closely with customers to develop tailored solutions that meet the most complex design requirements.

Cantilever V springs are an incredibly versatile and durable sealing solution for a wide range of industrial applications. Their unique construction—featuring a V-shaped metal spring embedded within a polymer jacket—gives them the ability to maintain high performance even under extreme conditions. They are ideal for hydraulic cylinders, pumps, compressors, and reciprocating rod applications, especially in environments involving high pressure, viscous fluids, and mechanical shocks.

With a wide temperature range, excellent deflection properties, and various material options, Cantilever V springs can be tailored to suit specific needs, from general-purpose sealing to specialized industrial applications. The availability of continuous lengths, pre-cut sizes, and custom geometries makes them highly adaptable to both small-scale and large-scale production environments.

When choosing a sealing solution that offers reliability, durability, and versatility, Cantilever V springs are an excellent choice. Whether you’re dealing with extreme temperatures, chemical exposure, or dynamic motion, Cantilever V springs provide the performance and longevity needed to keep your systems running smoothly.

For more information on how Cantilever V springs can improve your sealing solutions, please contact us. We are here to assist with custom orders, technical advice, and finding the right solution for your unique application.