Spring-energized seals are advanced sealing solutions that combine the benefits of spring-loaded technology with elastomeric or polymeric sealing elements. These seals are designed to provide consistent and reliable sealing under extreme conditions, such as high pressure, temperature fluctuations, and exposure to aggressive chemicals or harsh environments. In this article, we will explore the detailed features, advantages, and applications of spring-energized seals, while also addressing the key considerations for their use.

This in-depth guide serves as an essential resource for industries that rely on sealing technologies to ensure optimal performance and safety.

Spring-energized seals are designed to maintain their sealing integrity even in demanding environments. The seals consist of a flexible sealing element, typically made from materials such as rubber, PTFE (polytetrafluoroethylene), or other advanced polymers. This sealing element is supported by a spring, which is usually made from stainless steel, Inconel, or another corrosion-resistant material. The spring helps apply consistent pressure to the sealing lip, ensuring that it remains in contact with the mating surface, regardless of fluctuations in pressure, temperature, or other environmental factors.

The combination of a flexible sealing material and a spring component allows the seal to respond dynamically to changes in its environment. This ensures that the seal can withstand extreme conditions without losing its integrity.

Spring-energized seals come in different configurations, depending on the type of spring used. The most common types include:

Each spring type offers unique characteristics, making it important to choose the right configuration based on the specific application requirements.

Spring-energized seals offer several unique characteristics that distinguish them from conventional seals:

The spring inside the seal ensures that it maintains constant contact with the mating surface, compensating for any wear or thermal expansion that occurs during operation. This self-adjusting feature prolongs the seal’s life and ensures consistent performance even in harsh environments.

Unlike traditional elastomeric seals, spring-energized seals can withstand much higher pressures. The spring-loaded mechanism enhances the sealing element’s ability to stay in contact with the surface under extreme pressure, providing reliable sealing even in high-pressure environments.

The materials used in spring-energized seals are chosen for their resistance to a wide range of chemicals and temperature extremes. Polymers such as PTFE offer excellent chemical resistance, while the metallic spring component can withstand corrosion and harsh chemicals. This makes spring-energized seals ideal for applications involving aggressive media or exposure to high and low temperatures.

Thanks to their self-adjusting nature, spring-energized seals tend to last longer than conventional seals. The continuous force applied by the spring helps the seal maintain its shape and functionality over an extended period, reducing the need for frequent maintenance or replacements.

Spring seals are suitable for both static and dynamic applications. Whether the equipment requires stationary sealing or involves motion, these seals provide a reliable solution.

Spring-energized seals are used across a wide variety of industries due to their ability to perform under extreme conditions. Some key applications include:

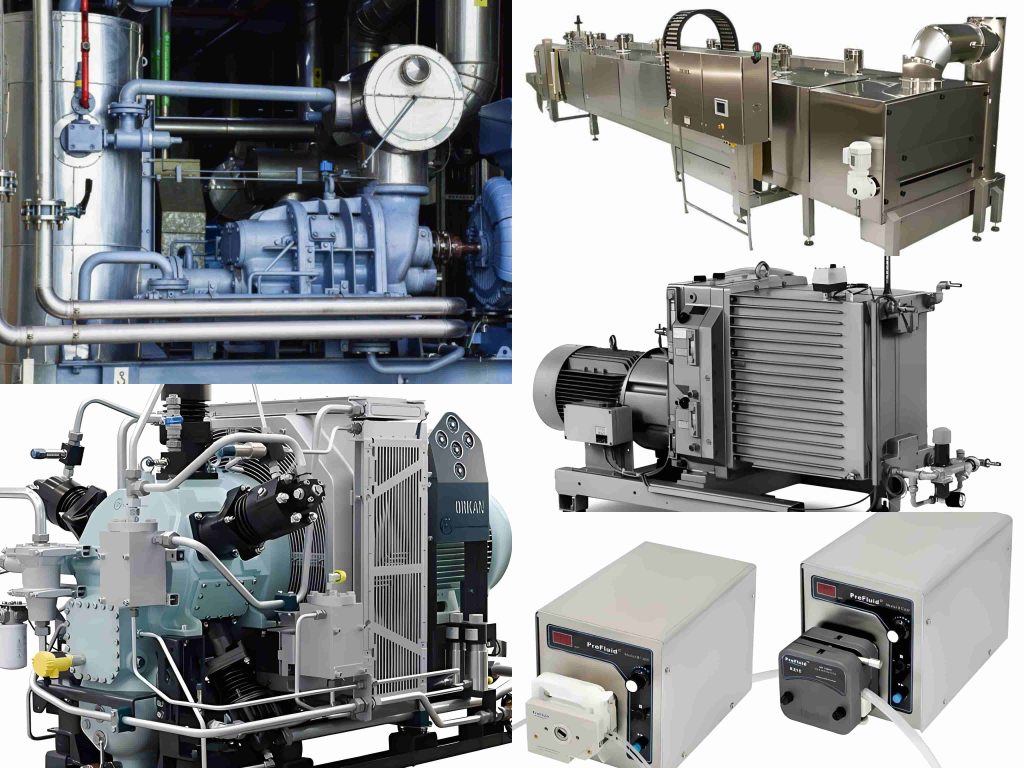

Spring-energized seals are extensively used in industrial machinery and equipment where performance and durability are critical. Common applications include:

In the medical and life sciences sectors, spring-energized seals are used in equipment that requires precision and cleanliness:

The aerospace and defense sectors demand seals that can operate in extreme environments, such as in high-altitude or space applications. Spring-energized seals provide reliable sealing solutions for:

In automotive applications, spring-energized seals provide solutions for critical systems such as:

The oil and gas industry relies on spring-energized seals for applications where exposure to extreme pressures, temperatures, and aggressive chemicals is common. These seals are used in:

Semiconductor manufacturing requires high levels of precision and cleanliness. Spring-energized seals are used in vacuum systems and cleanrooms to provide leak-free performance and maintain the integrity of manufacturing processes.

Spring-energized seals offer several advantages over conventional sealing solutions, making them a preferred choice for demanding applications:

Spring energized seals are designed to perform in extreme conditions where conventional seals might fail. Their ability to self-adjust and maintain consistent pressure on the sealing surface ensures reliability, even in the face of wear, temperature changes, or chemical exposure.

These seals are capable of operating in a broader range of conditions, including high-pressure, high-temperature, and low-temperature environments. This makes them ideal for applications that push beyond the limits of traditional elastomeric seals.

Due to their durable design and self-adjusting capability, spring-energized seals require less frequent maintenance. This reduces downtime and associated costs, making them a cost-effective solution in the long run, despite their higher initial cost.

The combination of advanced polymers and metallic springs allows these seals to withstand a wide variety of chemicals and extreme temperatures. This makes them particularly suitable for use in industries such as chemical processing, oil and gas, and pharmaceuticals, where exposure to aggressive chemicals and fluctuating temperatures is common.

Spring-energized seals are suitable for both static and dynamic applications. Whether used in stationary machinery or in equipment that requires motion, these seals provide consistent and reliable performance.

Spring-energized seals provide valuable solutions for industries that require superior sealing performance under challenging conditions. Some of the key industries include:

Despite their many advantages, there are several factors to consider when selecting and using spring-energized seals:

Compared to conventional seals, spring-energized seals are more expensive. However, the long-term benefits, such as reduced maintenance and extended lifespan, often offset the higher initial investment.

Spring energized seals require careful consideration of design parameters, such as the type of spring, the material of the sealing element, and the specific application conditions. Additionally, installation may require specialized tools or techniques to ensure proper alignment and functionality.

Not all applications require the advanced capabilities of spring-energized seals. It’s important to assess whether the specific requirements of the application justify the use of these seals.

Spring energized seals provide a superior sealing solution for applications that demand reliability, durability, and resistance to extreme conditions. While they come with a higher initial cost and complexity, their ability to perform under high pressure, temperature extremes, and exposure to aggressive chemicals makes them indispensable in critical industries such as aerospace, oil and gas, and medical devices. By choosing the right type of spring-energized seal for the application, companies can improve system reliability, reduce maintenance costs, and extend the lifespan of their equipment.

For industries requiring advanced sealing solutions, spring-energized seals offer unmatched performance and peace of mind in even the most challenging environments.