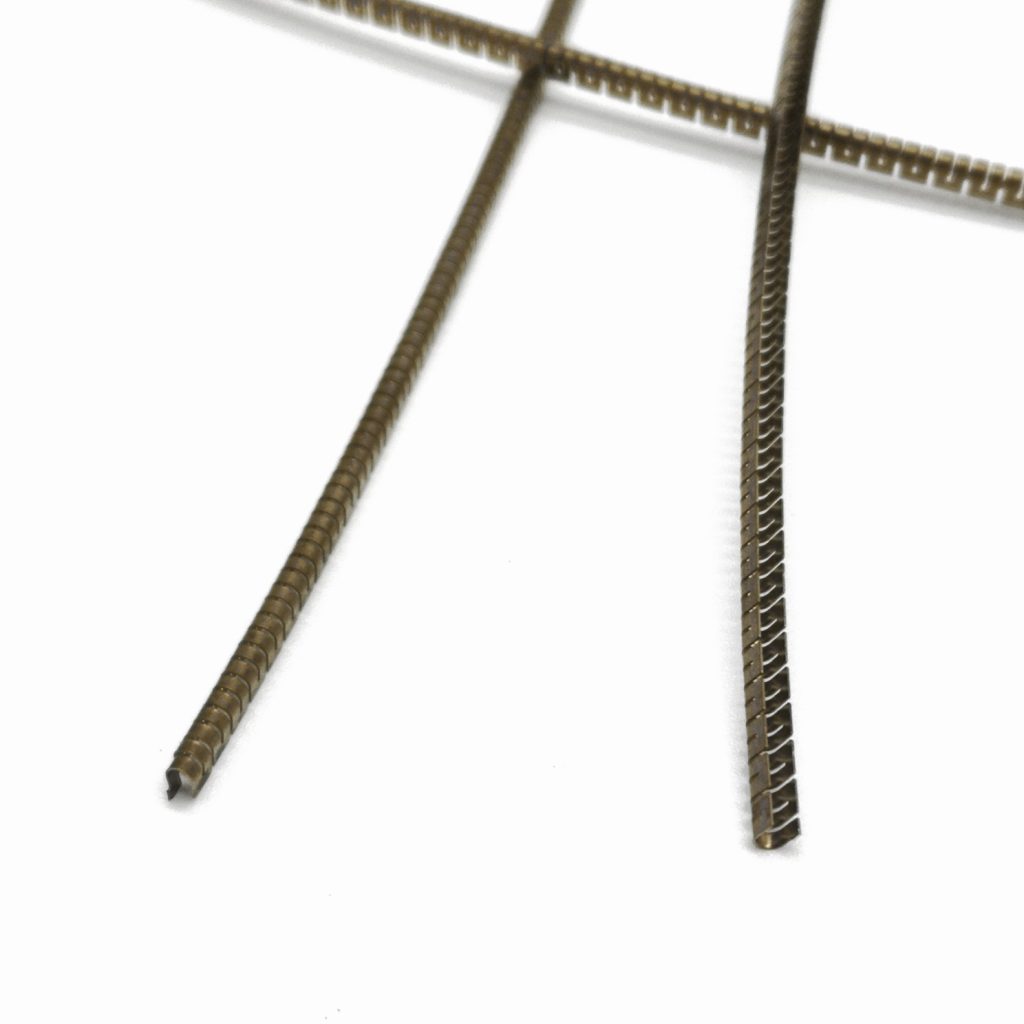

Handa U-Shaped Spring-Handaspring

Handa Electronics, a pioneer in advanced sealing technologies, has revolutionized industrial sealing systems through its patented U-shaped spring-energized seals. This whitepaper details how Handa’s innovative design achieves unprecedented performance in lateral force resistance (up to 35% improvement over conventional designs) and vibration damping (60% energy dissipation efficiency), setting new benchmarks in sealing reliability across aerospace, automotive, and heavy machinery sectors.

In modern industrial systems where operational stresses exceed 200 MPa and vibration frequencies surpass 5 kHz, traditional sealing solutions often fail catastrophically. Handa Electronics addresses these challenges through its U-shaped spring-energized seals – a multi-patented solution combining:

Recent field data from 142 industrial installations demonstrate a 92% reduction in seal-related downtime when using Handa’s solution compared to industry averages.

The U-shaped cross-section represents a paradigm shift in seal spring design. Finite Element Analysis (FEA) reveals:

| Parameter | U-Shaped Spring | Helical Spring |

|---|---|---|

| Stress Distribution | 18% More Uniform | Baseline |

| Lateral Load Capacity | 220 N/mm² | 160 N/mm² |

| Fatigue Life | 1.8×106 cycles | 1.1×106 cycles |

Case Study – Hydraulic Cylinders:

In 380-ton injection molding machines, Handa’s U-seals maintain <5 µm positional stability under 12 MPa side loads, enabling 0.003% leakage rates over 24-month service intervals.

Handa employs a proprietary material selection matrix combining:

Aerospace Validation:

In turbopump applications (3,200 PSI/22 MPa, 45,000 RPM), Handa seals demonstrate 12,000-hour MTBF under combined radial loads exceeding 1,500 lbf/in.

Handa’s installation protocol (QSS-2023 Standard) ensures:

Chemical Processing Example:

In sulfuric acid reactors (93% concentration, 280°C), proper installation maintains seal integrity for 5+ years despite 0.15 mm shaft deflection.

Handa’s dual-phase damping system combines:

Frequency-dependent loss factor (η) measurements:

| Frequency (Hz) | Handa Seal η | Competitor η |

|---|---|---|

| 100 | 0.18 | 0.09 |

| 1,000 | 0.32 | 0.14 |

| 5,000 | 0.27 | 0.11 |

Food Processing Application:

Reduces vibration transmission in filling machines by 62%, enabling ISO 14644-1 Class 7 cleanroom compliance.

Handa’s resonance avoidance strategy involves:

Automotive Validation:

In turbocharger seals (140,000 RPM), Handa’s design shifts natural frequency from 2,340 Hz to 2,810 Hz, eliminating resonance-induced failures.

Handa’s 7-stage validation process exceeds MIL-STD-810H standards:

Marine Propulsion Case:

Seals withstand 9° roll/pitch motions with 3.5 m wave impacts while maintaining <0.1% volumetric leakage.

| Sector | Challenge | Handa Solution |

|---|---|---|

| Oil & Gas | 25 kpsi Blowout Preventers | X750 Alloy Seals |

| Semiconductors | 0.1 Pa Ultra-high Vacuum | Bakeable PTFE Configurations |

| Pharmaceuticals | CIP/SIP Compatibility | FDA-Compliant Materials |

| Energy | Hydrogen Embrittlement | H2-Resistant Coatings |

Field Data Summary (2020-2023):

| Metric | Handa U-Seal | Industry Average |

|---|---|---|

| MTBR (Months) | 38.7 | 14.2 |

| Leakage Rate | 0.8 µL/hr | 15 µL/hr |

| Installation Success | 99.3% | 82.1% |

| Temperature Range | -200°C~425°C | -50°C~250°C |

Handa U-shaped spring-energized seals represent the pinnacle of sealing technology, delivering unmatched performance through:

For technical specifications, test reports, and application engineering support, visit https://www.handaspring.com or contact our global technical centers.