Springs are a kind of Machine element that uses elasticity to work. Generally made of spring steel. It is widely used in machines and instruments to control the movement of machinery components, mitigate impacts or vibrations, store energy, and measure the magnitude of force.

According to shape, there are mainly spiral springs, scroll springs, plate springs, etc. Its main functions include:

① controlling the movement of machinery, such as valve springs in internal combustion engines and control springs in clutches.

② Absorb vibration and impact energy, such as buffer springs under cars and train carriages, vibration absorbing springs in couplings, etc

③Store and output energy as power, such as clock springs, springs in firearms, etc.

④ It is used as a force measuring element, such as a force measuring device, a spring in a Spring scale, etc. The ratio of load to deformation of a spring is called spring stiffness, and the greater the stiffness, the harder the spring.

According to the nature of the force, springs can be divided into tension springs, compression springs, torsion springs, and bending springs. They can be divided into disc springs, ring springs, plate springs, spiral springs, truncated scroll springs, and torsion bar springs according to their shape. Ordinary cylindrical springs are most widely used due to their simple manufacturing and the ability to be made into various types according to load conditions, as well as their simple structure.

Generally speaking, the manufacturing materials of springs should have high Elastic Limit, Fatigue limit, impact toughness and good heat treatment performance. The common materials include carbon spring steel, alloy spring steel, stainless spring steel, copper alloy, nickel alloy and rubber.

There are two manufacturing methods for springs: cold coil method and hot coil method. Spring wire with a diameter less than 8mm is generally rolled using the cold rolling method, while those with a diameter greater than 8mm are rolled using the hot rolling method. Some springs require strong pressure or shot peening treatment after production, which can improve the bearing capacity of the spring.

Spring is a widely used elastic component in the mechanical and electronic industries. When loaded, a spring can generate significant elastic deformation, converting mechanical work or kinetic energy into deformation energy. After unloading, the deformation of the spring disappears and returns to its original state, converting deformation energy into mechanical work or kinetic energy.

The main functions of spring include: ① force measurement, such as the spring of Spring scale and gauge; ② Control movements such as clutches, brakes, and valve control springs; ③ Damping and buffering, such as buffers, shock absorber springs, etc.; ④ Energy storage or transmission, such as springs on clocks, instruments, and automatic control mechanisms.

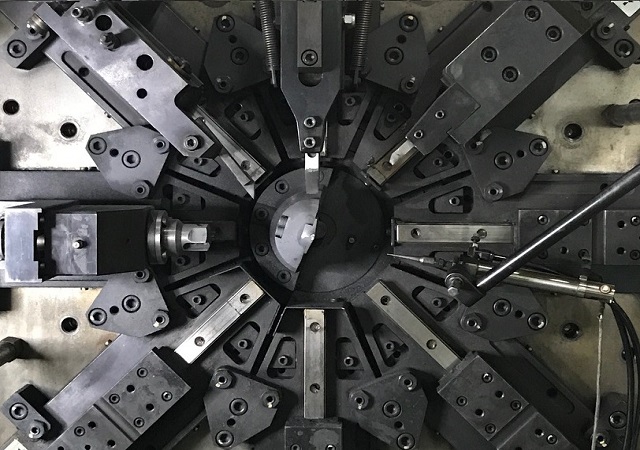

Types of springs: There are many types of springs, including compression springs, tension springs, torsion springs, and metal wire forming.