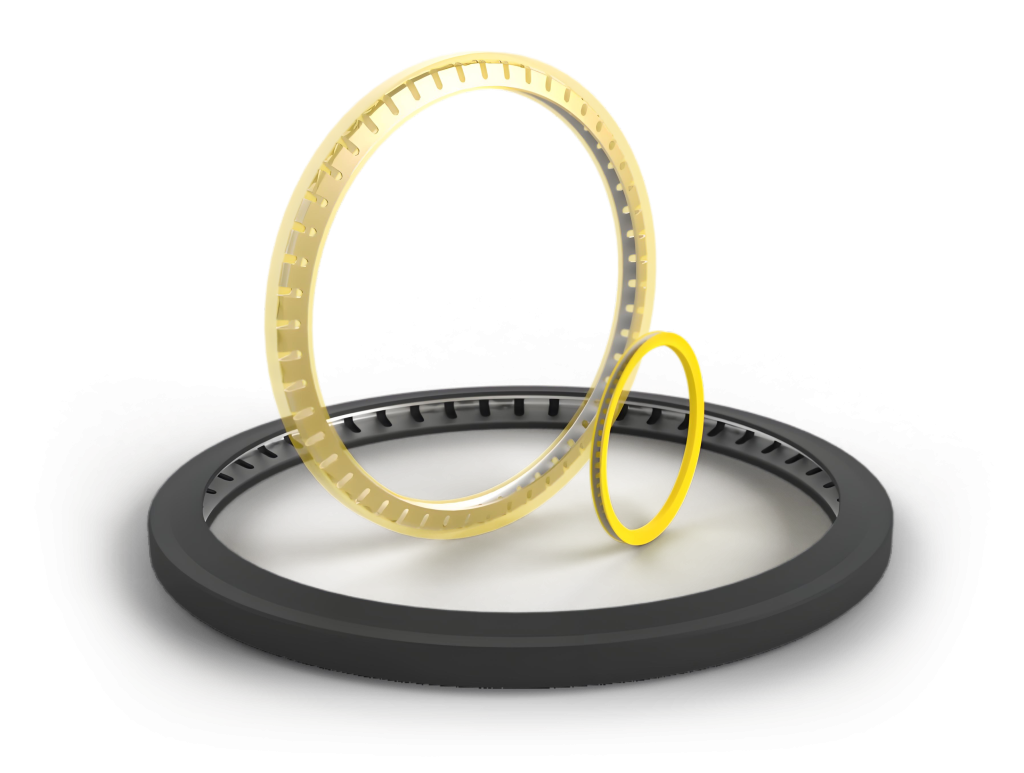

Full contact springs, also known as constant force or constant load springs, are mechanical devices designed to exert a consistent force throughout their deflection range. Unlike traditional springs that exert varying force based on displacement, full contact springs maintain a uniform force, making them ideal for applications requiring precise and predictable force output.

In the automotive industry, full contact springs are integral to several critical systems. Their reliability and durability make them ideal for use in:

In the medical field, full contact springs are found in various surgical instruments and devices where precision and consistency are critical:

The consumer electronics industry benefits from the use of full contact springs in several applications:

In aerospace applications, full contact springs are valued for their ability to perform under extreme conditions:

Industrial machinery applications benefit from the high force output and compact design of full contact springs:

Clamping Mechanisms: They are used in clamping mechanisms and adjustable fixtures to ensure consistent pressure and alignment, which is essential for maintaining precision and quality in manufacturing processes.

Conveyor Systems: In conveyor belts and automated machinery, these springs provide the necessary tension and control for smooth operation and load handling.

Full contact springs offer several significant advantages that make them suitable for demanding applications across various industries:

Full contact springs are designed to deliver a consistent force output throughout their entire range of motion. This characteristic ensures reliable performance in applications requiring precise force control, enhancing the overall efficiency and accuracy of the systems in which they are used.

Due to their design, these springs experience reduced stress and fatigue compared to traditional springs. This durability results in a longer service life, reducing the need for frequent replacements and maintenance. The extended lifespan contributes to lower overall operating costs and increased reliability.

Full contact springs provide high force in a compact space, making them ideal for applications with constrained environments. Their ability to deliver significant force while occupying minimal space allows for more flexible and efficient design options in both mechanical and electronic systems.

The continuous contact design of these springs ensures smooth and controlled operation, minimizing jerks and vibrations. This smooth operation is particularly important in applications where precise and consistent performance is required, such as in consumer electronics and medical devices.

By providing a constant force output, they contribute to the overall efficiency of mechanical systems. Their design helps in maintaining optimal performance, reducing energy consumption, and enhancing the effectiveness of various applications.

By leveraging the benefits of full contact springs, industries can enhance the functionality and durability of their products, leading to improved performance and reduced maintenance costs.For detailed information on selecting and utilizing these springs, consulting with our experienced spring manufacturers is recommended.