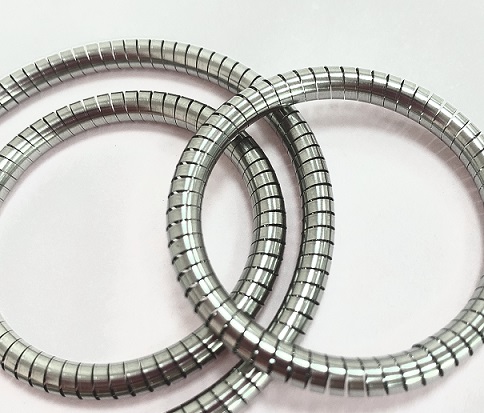

Helical spring design principles involve various aspects, including material selection, size determination, and spring constant calculation.

Working Principle: A helical spring is an elastic component whose operation is based on elastic deformation. When subjected to an external force, the helical spring undergoes deformation, storing elastic potential energy. When the external force is removed, the spring returns to its original state, releasing the stored energy.

Material Selection: Choosing the appropriate material is a critical aspect of helical spring design. Common spring materials include spring steel, stainless steel, and alloy steel. Material selection is influenced by factors such as application environment, operating temperature, and elastic modulus.

Spring Constant: The spring constant, often denoted as ‘k,’ is a parameter describing the stiffness of the spring. It is related to the geometric shape and material properties of the spring. Calculating the spring constant is crucial for predicting and designing the spring’s performance.

Size and Geometric Shape: Parameters such as diameter, pitch, and number of coils directly impact the stiffness and elastic behavior of the spring. Design considerations need to account for these dimensions to meet specific operational requirements.

End Design: The design of the spring ends is a crucial factor. Different end forms, such as open coil ends, closed coil ends, or ground ends, can affect the spring’s connection method and performance.

Preloading and Torsion: Consideration of preloading (preload) and torsion effects is necessary in spring design. Preloading involves applying a certain initial load before spring installation, while torsion refers to the spring’s behavior during twisting or rotation.

Fatigue Life: Helical springs may undergo repeated loading and unloading during long-term use, so considering fatigue life is essential in the design process. A well-designed spring can extend its operational lifespan.

These principles in helical spring design are interrelated. And designers need to comprehensively consider these factors to ensure the spring operates stably and reliably in specific applications. In practical design, material testing and simulation analysis are often conducted to validate the design’s feasibility.