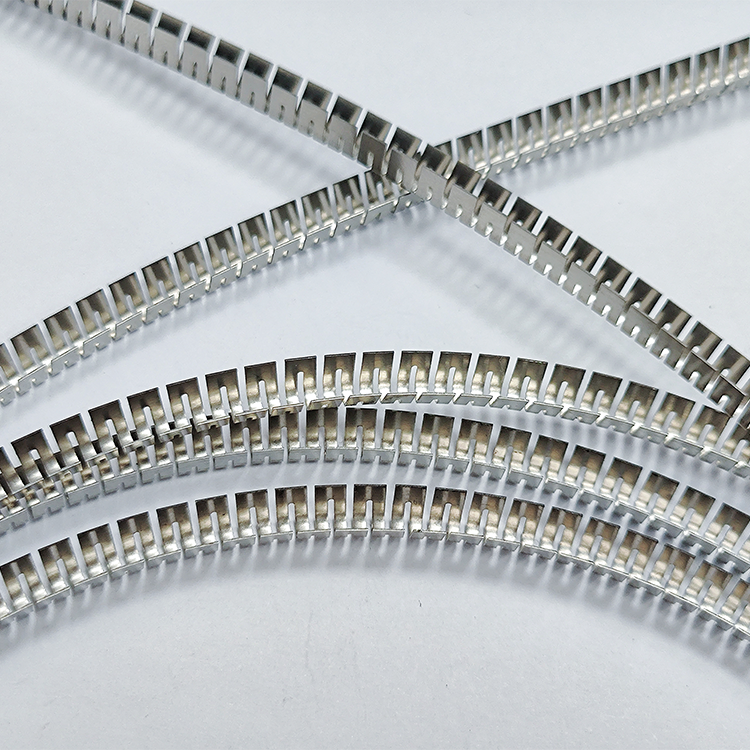

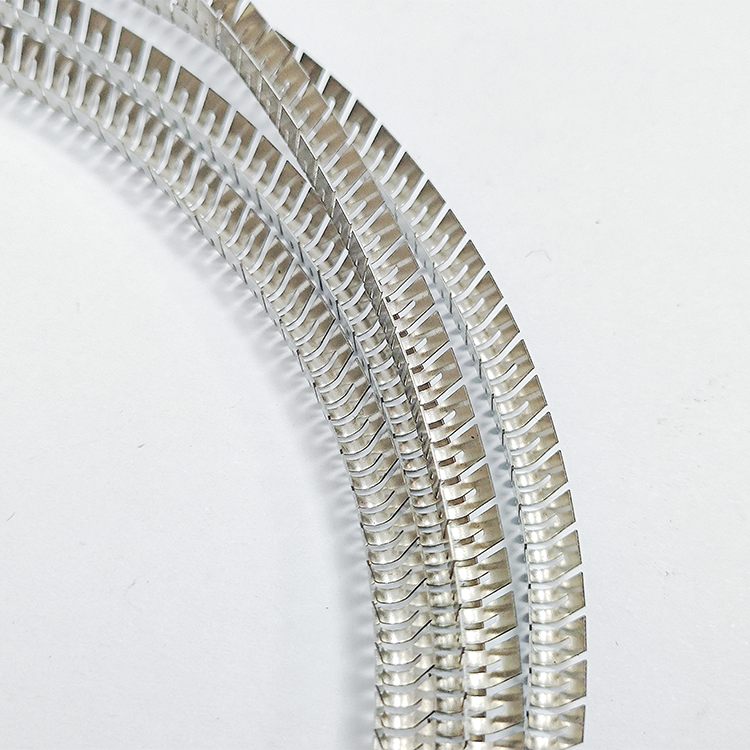

The spring constant of a Cantilever V Spring, or any spring, significantly affects its performance in various ways, including its ability to store and release energy, its response to loads, and its overall durability.

Here’s how the spring constant influences the performance of a V-spring:

1.Stiffness and Resistance to Deformation: The spring constant directly determines the stiffness of the spring. A higher spring constant means the spring is stiffer and more resistant to deformation. This is crucial for applications where the spring needs to maintain its shape or position under load, such as in suspension systems or mechanical components that require precise positioning.

2.Energy Storage and Release: The spring constant affects how much energy the spring can store when compressed and how quickly it can release this energy when the load is removed. A higher spring constant allows the spring to store more energy, which can be beneficial in applications requiring high energy storage, such as in shock absorbers or springs used in machinery.

3.Durability and Lifespan: Cantilever V Spring constant is also related to the durability and lifespan of the spring. Springs with a higher spring constant are generally more durable and can withstand higher loads without deforming significantly. However, if a spring exceeds its elastic limit, it may experience work hardening, leading to changes in its rate and potentially early failure. Fatigue failure can occur over a large number of cycles within the elastic limit, causing local overloading and gradual crack growth until the crack reaches a critical length, leading to rapid propagation and failure.

4.Temperature Sensitivity: Cantilever V Spring constant is affected by temperature changes. As temperature increases, the spring constant generally decreases because the material of the spring expands, reducing its stiffness. Conversely, as temperature decreases, the spring constant increases, making the spring stiffer. This temperature sensitivity can impact the performance of the spring in real-life applications, such as in vehicles where changes in temperature can affect the handling and ride comfor.

5.Material and Manufacturing Process: The type of material and the manufacturing process used to create Cantilever V Spring can also influence the spring constant. Different materials have different molecular structures and will respond differently to changes in temperature, affecting the relationship between spring constant and temperature. Some materials may have a more significant change in spring constant with temperature than others.

In summary, the spring constant plays a critical role in determining the performance of a Cantilever V Spring, affecting its stiffness, energy storage and release capabilities, durability, and temperature sensitivity. Understanding these factors is essential for selecting the appropriate spring for specific applications and ensuring its optimal performance.