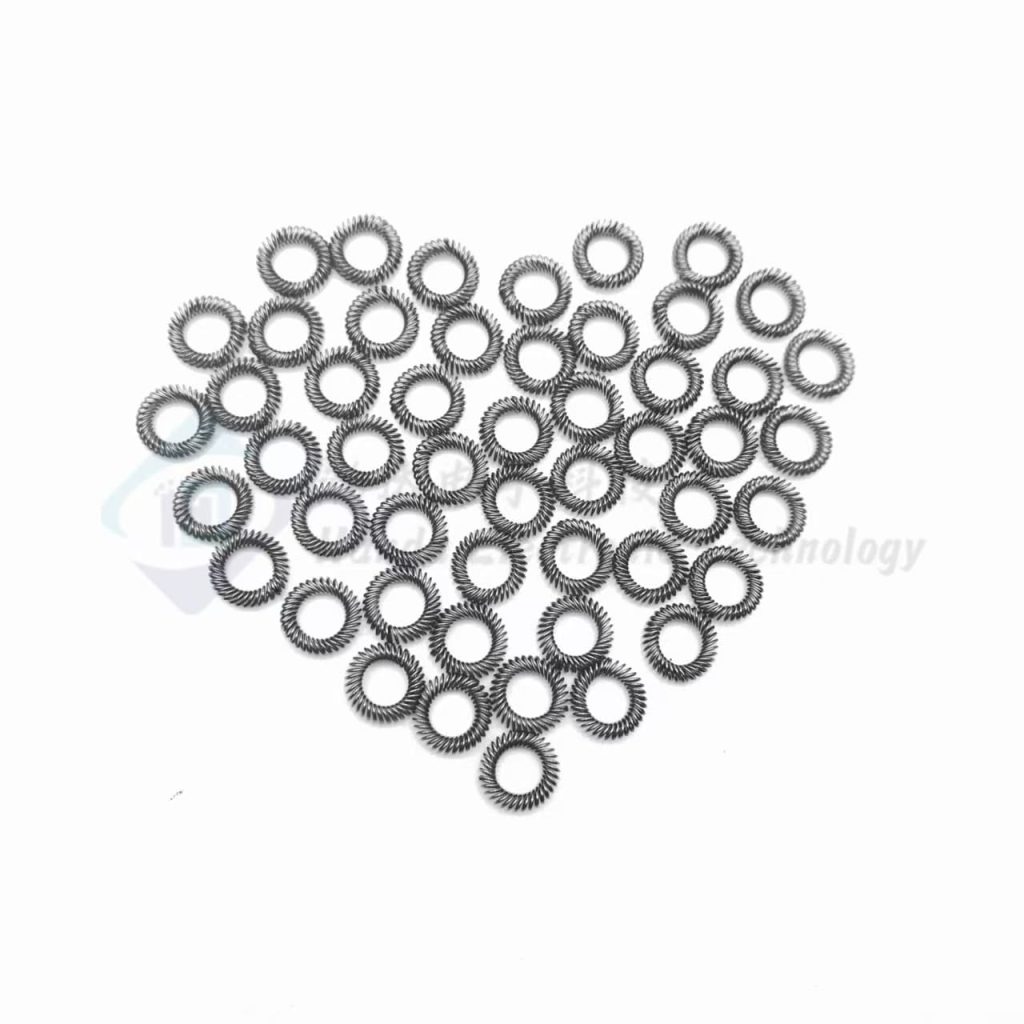

のトップ・ミスを学ぼう コイルスプリング 溝設計とその回避方法。適切な溝形状により、性能、接触力、寿命を向上させます。.

コイルスプリングは 電気接点、EMIシールド、シーリングシステム、精密メカニカルアセンブリ. .エンジニアは材料の選択やバネの力に焦点を当てることが多い、, グルーブデザイン は、信頼できるパフォーマンスを達成するために非常に重要である。.

溝の形状が不適切な場合、次のようなことが起こり得る。 不均等な荷重配分、早期摩耗、接触力の損失、さらにはスプリングの不具合。. .この記事では、その概要を説明する。 カント付きコイルスプリングの溝設計で最もよくある間違い また、エンジニアが性能と寿命を最適化できるよう、ベストプラクティスのガイダンスを提供しています。.

従来の圧縮スプリングとは異なる、, カントコイルスプリングは、制御された横方向の動きに依存する 溝の中にある。溝は直接影響する:

高品質なキャントコイルスプリングであっても、溝の設計が悪ければ性能は低下する。.

最も一般的な間違いのひとつは、溝幅の指定が以下のいずれかであることだ。 狭すぎたり広すぎたり.

溝の幅は 制御されたラジアル方向とアキシャル方向の動き スプリングがねじれたりつぶれたりしないように。常にスプリングメーカーの推奨公差に従ってください。.

溝の深さは、しばしば過小評価されたり、圧縮スプリングの設計からコピーされたりする。 カント付きコイルスプリングには適さない.

溝の深さに対応しなければならない:

適切に設計された溝は、スプリングが最適なたわみ量の範囲内で動作することを保証します。.

鋭利な溝のエッジや粗い加工面は、取り付け時や操作時にスプリングを損傷する可能性があります。.

これは特に重要である。 金メッキまたは銀メッキカントコイルスプリング 電気的用途に使用される。.

設計者は、機械加工を単純化したりコストを削減するために、過度に緩い公差を適用することがある。.

厳しいが現実的な公差が確保されている:

すべての溝が長方形である必要はない。用途によっては U字溝、V字溝、または段付き溝, しかし、これは見過ごされがちだ。.

溝形状を選択する:

設計段階の早い段階でキャントコイルスプリングメーカーに相談することで、コストのかかる再設計を防ぐことができます。.

グルーヴのデザインは、多くの場合、次のような影響を無視している。 熱膨張, 特に航空宇宙、自動車、半導体の用途において。.

アカウント

これにより、過酷な条件下でも安定した性能を発揮する。.

スプリングの材質が異なると、同じ溝設計でも挙動が異なる。.

溝のデザインは、それに合わせるべきである:

素材ごとに最適化することで、耐久性と機能性の両方が向上する。.

| デザイン・エレメント | よくある間違い | 推奨されるアプローチ |

|---|---|---|

| 溝幅 | きつすぎる、または緩すぎる | メーカー指定公差 |

| 溝の深さ | 圧縮スプリングをベースとする | コイルのたわみを考慮した設計 |

| エッジ・フィニッシュ | 鋭いエッジ、バリ | 放射状のエッジ、滑らかな仕上げ |

| 公差 | ルーズすぎる | 制御された、アプリケーション固有の |

| 溝の形状 | 一般的な長方形 | アプリケーションごとに最適化 |

溝の設計が最適化されると、カント付きコイルスプリングはその性能を発揮します:

信頼性の高いアプリケーション向け、, グルーブデザインはオプションではなく、エンジニアリングの重要なパラメータである。.

コイルスプリングが斜めになっていることが原因とされる故障の多くは、実は次のようなものである。 溝の設計が悪い, スプリングそのものではありません。これらのよくある間違いを避け、実証済みの設計原則に従うことで、エンジニアは性能、信頼性、製品寿命を大幅に向上させることができます。.

経験豊富なコンサルタントとの早期連携 コイルスプリング・メーカー これにより、溝形状、材料選択、公差がアプリケーションの要件に完全に適合し、時間、コスト、将来の再設計を削減します。.