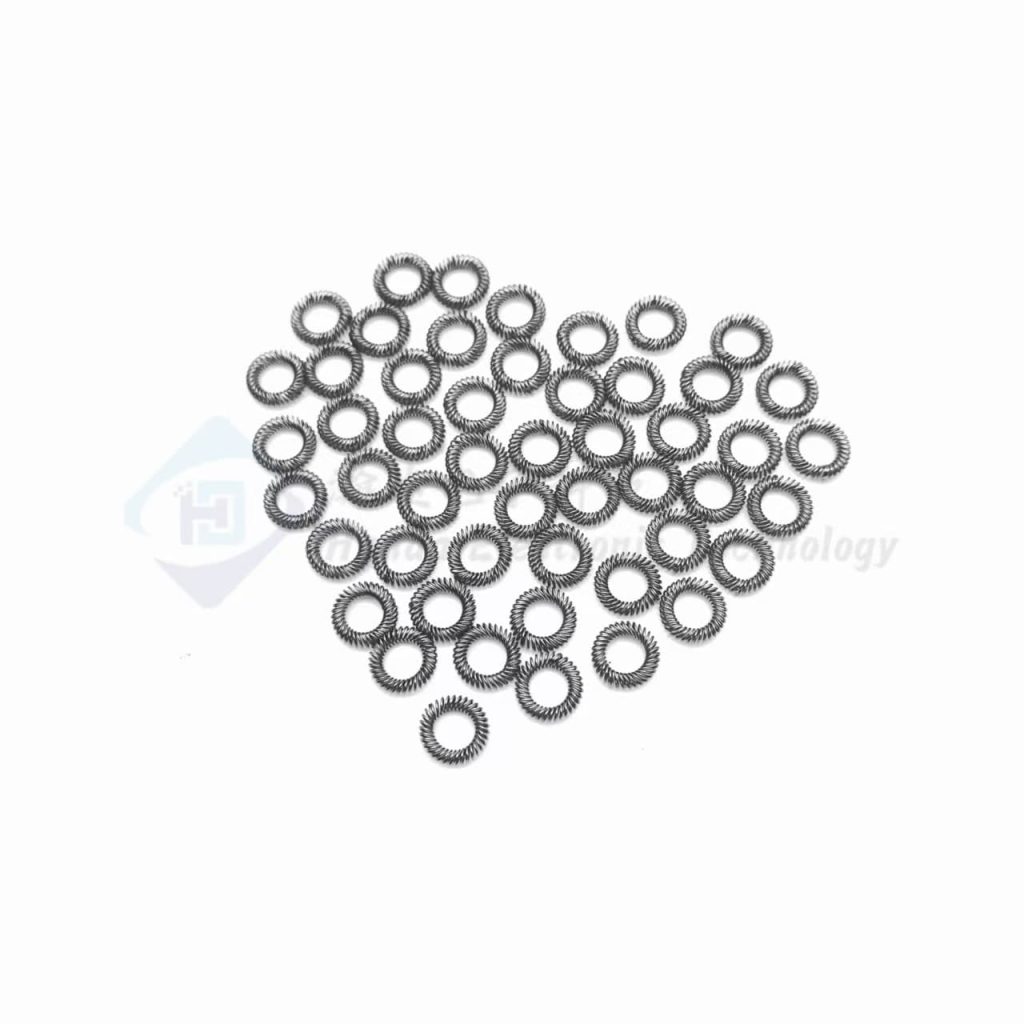

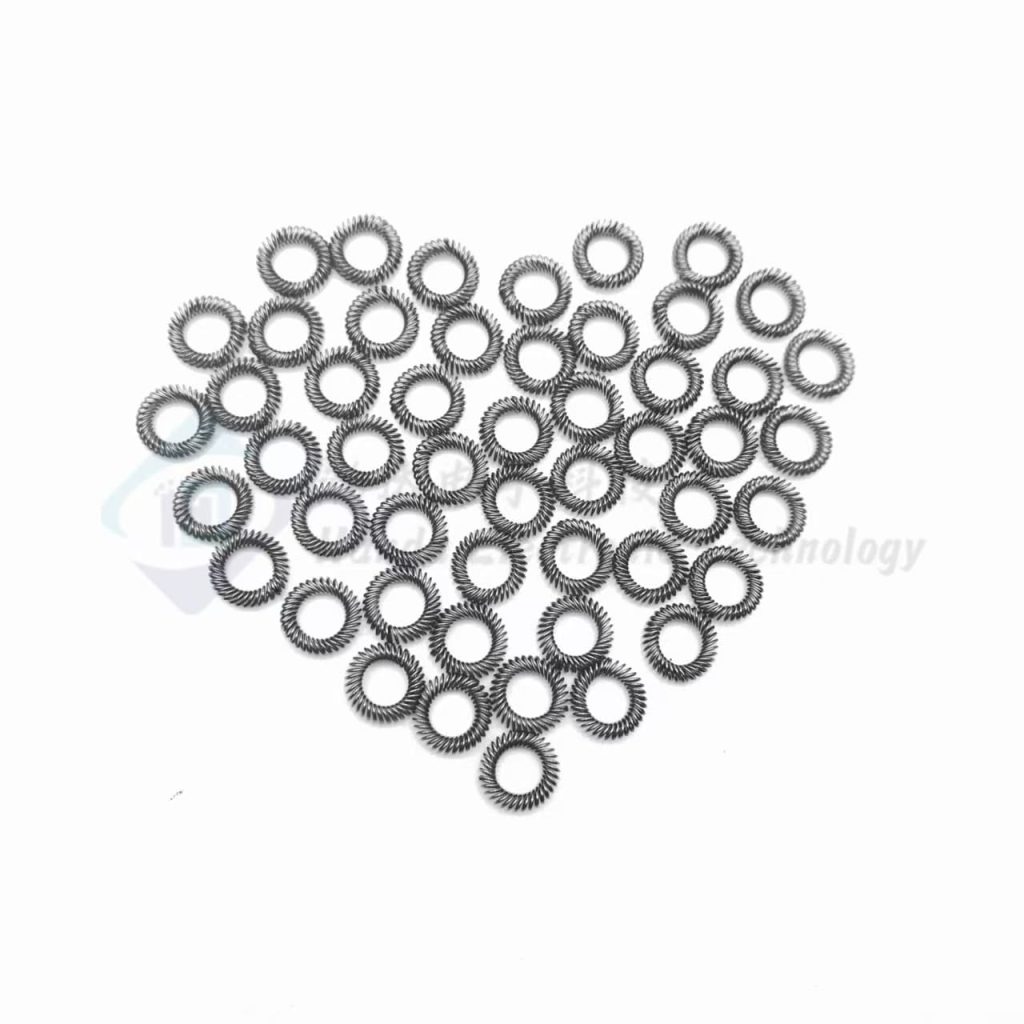

In industries where corrosion, high temperatures, and cyclic stresses compromise conventional springs, Hastelloy 276 canted coil springs provide unmatched reliability. Crafted from Hastelloy C-276 alloy—a nickel-molybdenum-chromium superalloy—these springs excel in the world’s most aggressive operational environments.

Hastelloy C-276 (UNS N10276) is a nickel-molybdenum-chromium-iron-tungsten alloy renowned for:

Survives prolonged exposure to harsh chemicals (e.g., sulfuric acid, chlorides) where standard springs fail. Eliminates premature corrosion failures in chemical processing equipment.

Maintains structural integrity under high-stress cyclic loading. Resists micro-crack formation for reliable performance in vibrating/pulsating systems.

Operates continuously from cryogenic (-253°C) 에 elevated temperatures (1093°C). Retains elastic modulus (~205 GPa) and tensile strength where other alloys soften.

Delivers precise, stable elastic force under mechanical stress. Resists permanent deformation even after prolonged compression.

Seals/reactor springs in acid environments. Used in:

Withstands sour gas (H₂S), CO₂, and acidizing fluids. Key uses:

Reliable performance in jet engines, fuel systems & hydraulic controls under:

Hastelloy 276 canted coil springs solve reliability challenges in corrosive, high-temperature, and high-fatigue applications. By leveraging the metallurgical excellence of Hastelloy C-276 alloy, these springs:

Specify Hastelloy C-276 canted coil springs for mission-critical resilience. 문의하기(kathy@handaspring.com) for technical datasheets and application engineering support.