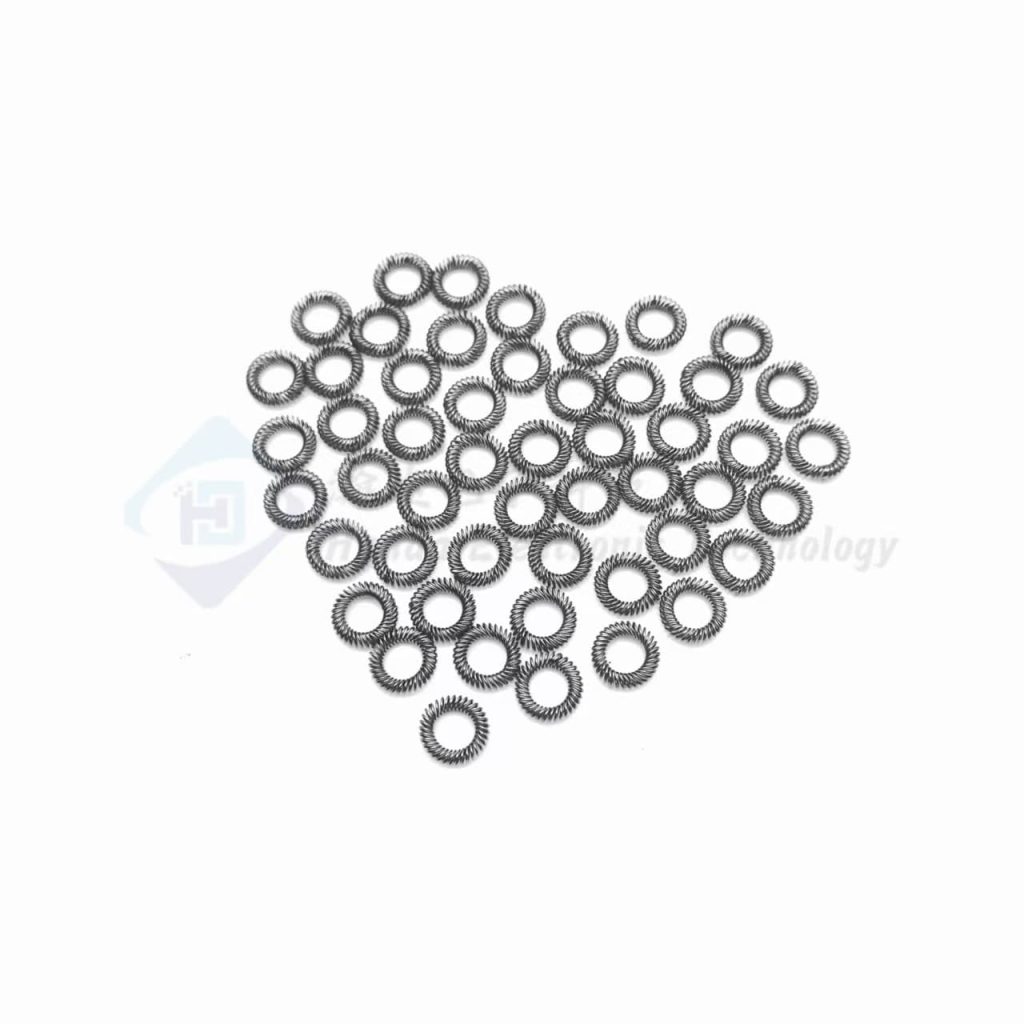

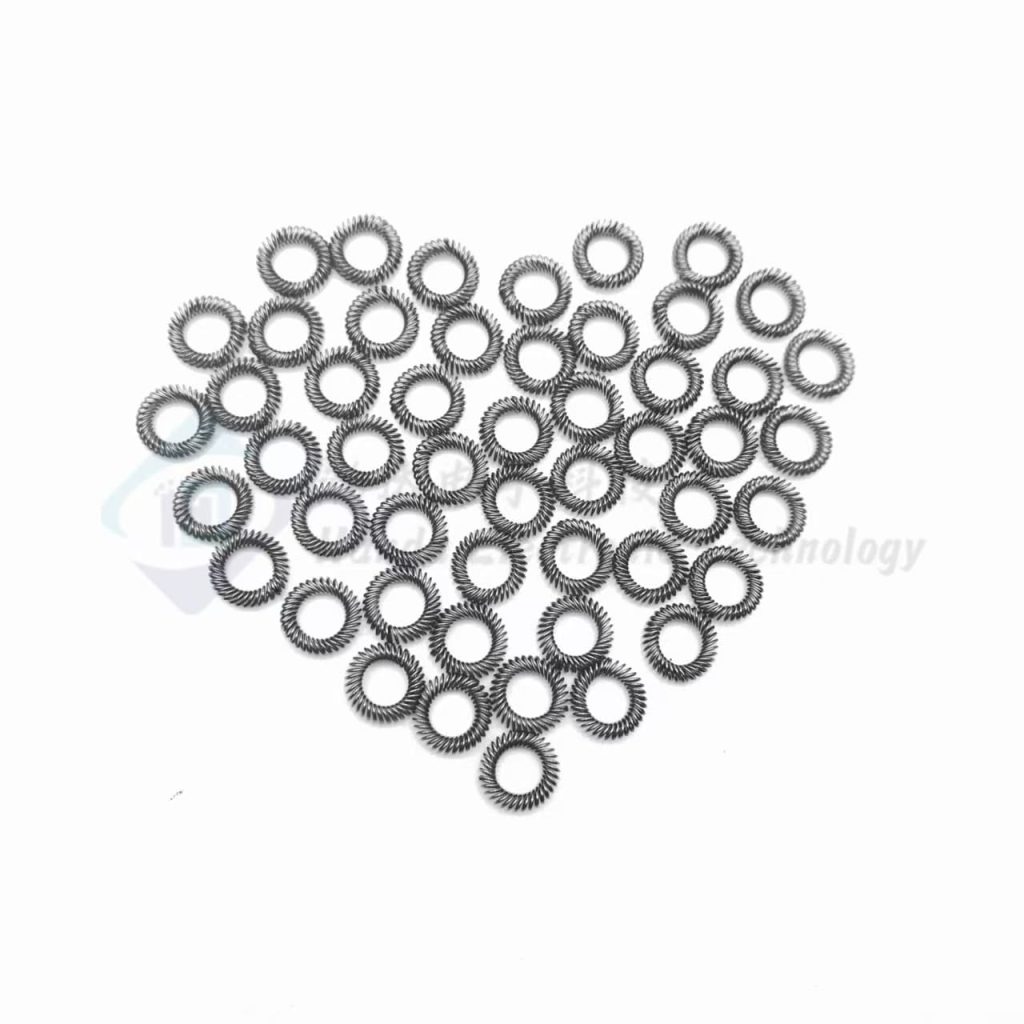

Используются в отраслях, где коррозия, высокие температуры и циклические нагрузки разрушают обычные пружины, Конические спиральные пружины из сплава Hastelloy 276 обеспечивают непревзойденную надежность. Изготовлен из Сплав Hastelloy C-276-Эти пружины, изготовленные из никель-молибден-хромового суперсплава, отлично работают в самых агрессивных условиях эксплуатации.

Хастеллой C-276 (UNS N10276) - это никель-молибден-хром-железо-вольфрамовый сплав, известный своими свойствами:

Выдерживают длительное воздействие агрессивных химических веществ (например, серной кислоты, хлоридов), когда стандартные пружины выходят из строя. Устраняет преждевременные коррозионные разрушения в оборудовании для химической обработки.

Сохраняет структурную целостность при циклических нагрузках. Противостоит образованию микротрещин, обеспечивая надежную работу в вибрирующих/пульсирующих системах.

Работает непрерывно от криогенный (-253°C) на повышенные температуры (1093°C). Сохраняет модуль упругости (~205 ГПа) и прочность на разрыв там, где другие сплавы размягчаются.

Обеспечивает точную, стабильную упругую силу при механических нагрузках. Сопротивляется постоянной деформации даже после длительного сжатия.

Уплотнения/пружины реакторов в кислотных средах. Используется в:

Выдерживает воздействие кислого газа (H₂S), CO₂ и окисляющих жидкостей. Основные области применения:

Надежная работа в реактивных двигателях, топливных системах и гидравлических системах управления:

Конические спиральные пружины из сплава Hastelloy 276 решают проблемы надежности в коррозионных, высокотемпературных и высокоусталостных приложениях. Благодаря использованию металлургического совершенства сплава Hastelloy C-276 эти пружины:

Укажите Конические спиральные пружины из сплава Hastelloy C-276 для обеспечения устойчивости критически важных задач. Свяжитесь с нами(kathy@handaspring.com) для получения технических паспортов и инженерной поддержки по применению.