Do you know the applications and characters about beryllium copper spiral tube?

Beryllium copper spiral tube shielding liner is an ideal shielding material for military and aerospace projects. Its cost is highly competitive, and it is also suitable for other civil electronic equipment with high screen efficiency requirements.

1) High shielding effectiveness, good elasticity, and resistance to permanent compression deformation.

2) Tin plating on beryllium copper spiral tubes can further improve their conductivity and shielding performance.

3) Pads with edge plating have strong electro-chemical corrosion resistance in humid and salt fog environments.

1) Materials

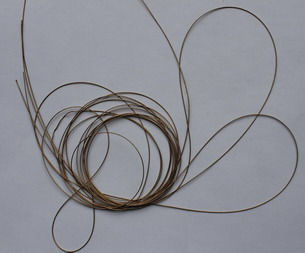

Spiral tube: beryllium copper nickel plated

Electroplated coating: nickel

Core: PVC hardness 80 (hard plastic)

The raw material is specially imported beryllium copper, which has passed the process of cutting, manufacturing, electroplating, and heat treatment. The performance test has reached foreign standards. After 2 years of installation and testing by users, it fully meets the requirements of screen efficiency, elasticity, corrosion prevention, and salt spray prevention.

2) Shielding effectiveness:

Raw material: Nickel Plated Copper Beryllium

Shielding quality: The shielding effect of this sealing gasket ranges from 80dB to 160dB.

3) Compression force:

This spiral tube shield gasket has the following three different compression forces. The ideal compression force is 25% of the spiral tube diameter. Since the pressure is related to the thickness of beryllium copper, the following values are only approximate.