Learn the top mistakes in скошенная спиральная пружина groove design and how to avoid them. Improve performance, contact force, and service life with proper groove geometry.

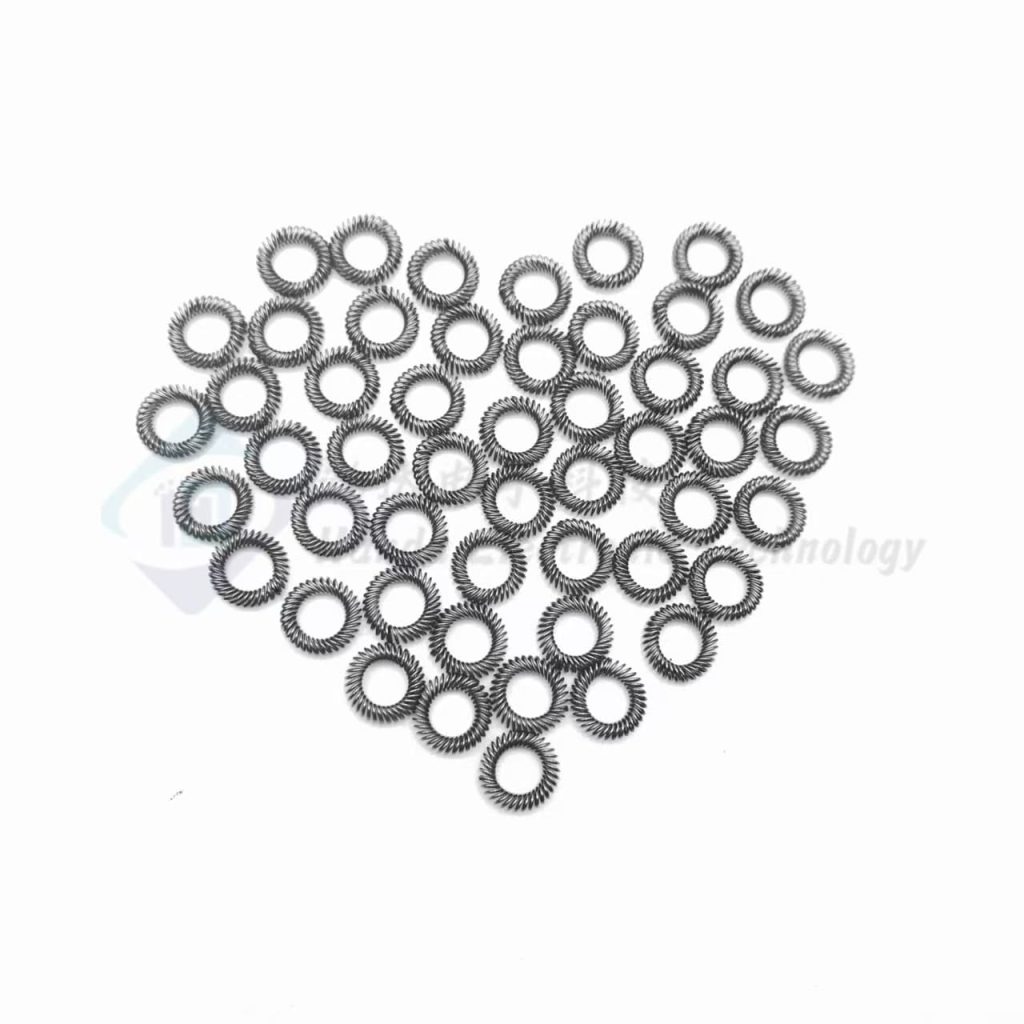

Canted coil springs are widely used in electrical contacts, EMI shielding, sealing systems, and precision mechanical assemblies. While engineers often focus on material selection or spring force, groove design is just as critical to achieving reliable performance.

Improper groove geometry can lead to uneven load distribution, premature wear, loss of contact force, and even spring failure. This article outlines the most common mistakes in canted coil spring groove design and provides best-practice guidance to help engineers optimize performance and longevity.

Unlike traditional compression springs, canted coil springs rely on controlled lateral movement within a groove. The groove directly affects:

Even a high-quality canted coil spring will underperform if the groove is poorly designed.

One of the most common errors is specifying a groove width that is either too narrow or too wide.

The groove width should allow controlled radial and axial movement without allowing the spring to twist or collapse. Always follow the spring manufacturer’s recommended tolerances.

Groove depth is often underestimated or copied from compression spring designs, which are not suitable for canted coil springs.

Groove depth must accommodate:

A properly designed groove ensures the spring operates within its optimal deflection window.

Sharp groove edges or rough machining surfaces can damage the spring during installation or operation.

This is especially critical for gold-plated or silver-plated canted coil springs used in electrical applications.

Designers sometimes apply overly loose tolerances to simplify machining or reduce cost.

Tight but realistic tolerances ensure:

Not all grooves should be rectangular. Some applications require U-shaped, V-shaped, or stepped grooves, but this is often overlooked.

Select groove geometry based on:

Consulting with a canted coil spring manufacturer early in the design phase can prevent costly redesigns.

Groove design often ignores the effects of thermal expansion, especially in aerospace, automotive, and semiconductor applications.

Account for:

This ensures stable performance under extreme conditions.

Different spring materials behave differently within the same groove design.

Groove design should be matched to:

Material-specific optimization improves both durability and functional performance.

| Design Element | Common Mistake | Recommended Approach |

|---|---|---|

| Groove Width | Too tight or too loose | Manufacturer-specified tolerance |

| Groove Depth | Based on compression springs | Designed for canted coil deflection |

| Edge Finish | Sharp edges, burrs | Radiused edges, smooth finish |

| Tolerances | Overly loose | Controlled, application-specific |

| Groove Shape | Generic rectangular | Optimized per application |

When groove design is optimized, canted coil springs deliver:

For high-reliability applications, groove design is not optional—it is a critical engineering parameter.

Many failures attributed to canted coil springs are actually caused by poor groove design, not the spring itself. By avoiding these common mistakes and following proven design principles, engineers can significantly improve performance, reliability, and product lifespan.

Early collaboration with an experienced canted coil spring manufacturer ensures that groove geometry, material selection, and tolerances are fully aligned with application requirements—saving time, cost, and future redesigns.