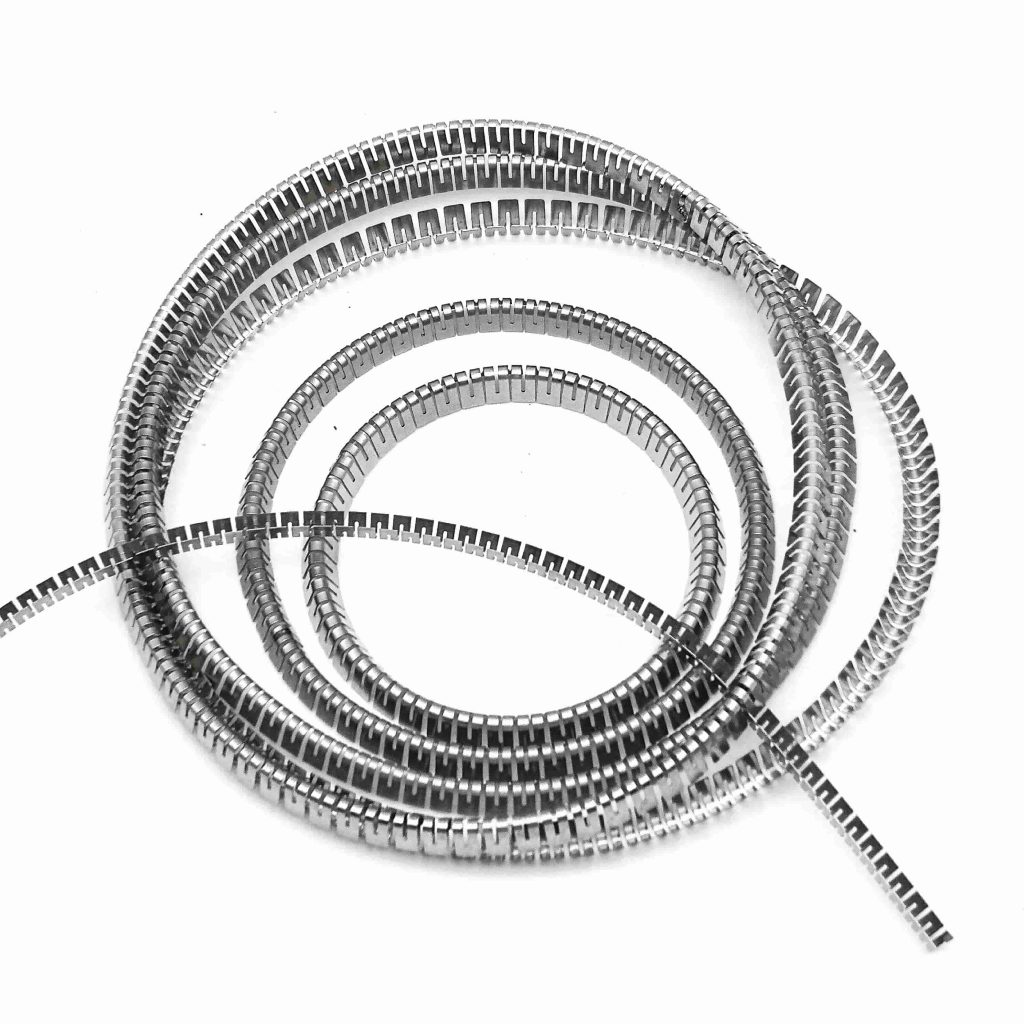

SS301 Cantilever V Springs in Different Sizes

SS301 Cantilever V Springs combine the unique V‑shaped geometry of cantilever springs with the high strength, excellent fatigue life, and good corrosion resistance of 301‑grade stainless steel. These springs exhibit high elastic limits, can be cold‑worked to achieve full‑hard tempers with tensile strengths up to 1 200 MPa, and maintain performance across a broad temperature range (from cryogenic to ~500 °C). Their V‑shaped cross‑section provides consistent preload and edge‑contact sealing, making them ideal for dynamic sealing in hydraulic, pneumatic, aerospace, and medical applications.

Cantilever V Springs are ribbon‑type springs formed into a V‑shaped profile that applies force primarily at the spring’s edges to maintain contact with a mating surface, such as a shaft or seal lip. This design ensures high sealing effectiveness and tolerance to misalignment under dynamic conditions. When fabricated from SS301, they combine mechanical resilience with corrosion resistance.

SS301 is an austenitic stainless steel alloy with the following typical composition ranges:

This balance of Cr and Ni delivers the austenitic microstructure that underpins SS301’s combination of ductility and strength.

Under cold‑working, SS301 achieves a wide range of tempers, from annealed to full hard, with corresponding mechanical properties:

High work‑hardening rates (~14 MPa per 1 % reduction) allow SS301 to reach very high strengths while retaining enough ductility for spring forming.

SS301 offers corrosion resistance comparable to grade 304 in mildly corrosive environments at ambient temperatures. It resists oxidation intermittently up to ~840 °C and continuously up to ~900 °C, making it suitable for elevated‑temperature applications. Below cryogenic temperatures, SS301 maintains toughness and elastic properties, enabling its use in both extreme cold and heat.

SS301 Cantilever V Springs are typically manufactured in compliance with:

SS301 Cantilever V Springs leverage the high strength, formability, and corrosion resistance of 301 stainless steel in a V‑shaped profile that delivers reliable, dynamic sealing across diverse industries. Their broad temperature range, fatigue life, and preload consistency make them indispensable for high‑performance sealing applications. Proper selection of temper, finish, and geometry ensures optimal performance in each targeted environment.