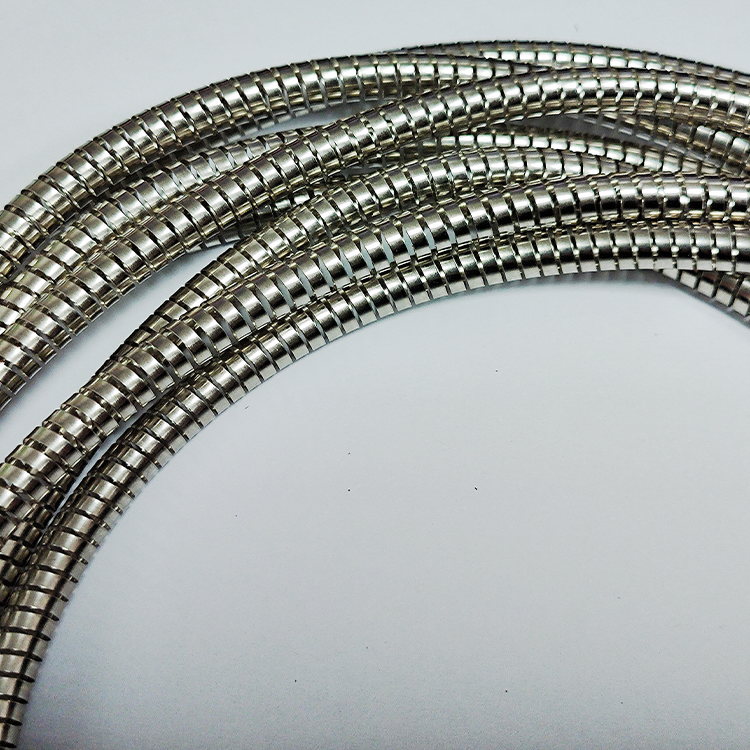

Helical springs contribute to the elasticity of permanent sealing sleeves by integrating mechanical performance and design considerations, thereby enhancing sealing effectiveness across various applications.

Adaptability to Flange Geometry and Defects: The utilization of helical springs in sealing applications allows for exceptional adaptability to flange geometry and defects. This adaptability is crucial for ensuring a lasting seal, as it enables the seal to conform precisely to the specific requirements of the application, including the shape and size of the flanges.

Controlled Compression and Load: Helical springs facilitate precise control over compression load and seating load, which are vital for maintaining a lasting seal. This control ensures that the seal is neither excessively tight (which could cause equipment damage) nor too loose (which would compromise its effectiveness).

Material and Sealing Level Selection: The selection of spring characteristics permits adjustment of compression load based on the type of lining material and required sealing level. This flexibility guarantees optimization of the seal for each specific application, providing necessary sealing performance.

In summary, helical springs contribute to sleeve elasticity by providing compensation for wear and deformation, allowing adaptability to flange geometry, enabling controlled compression and load management, as well as facilitating appropriate material selection and sealing levels. These features collectively ensure that seals remain effective and reliable throughout equipment lifespan.