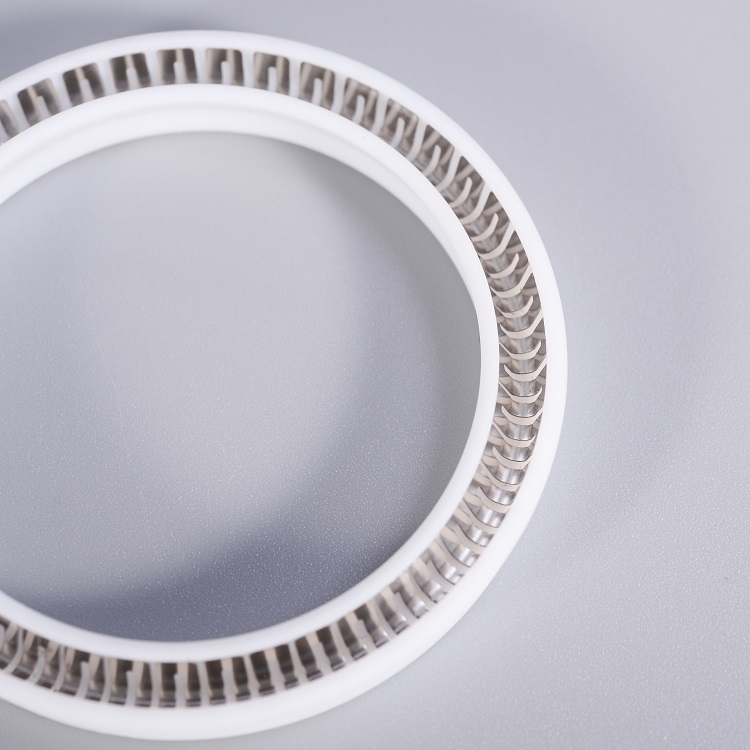

Pan plug sealing (spring energy storage sealing ring/Sealing Ring Springs) is a special sealing element developed for high-temperature corrosion, lubrication difficulties, and low friction application environments. The combination of different Teflon composite materials, engineering plastics, and corrosion-resistant metal springs can fully meet the increasingly demanding diversity needs of industry, such as food industry, medicine, petroleum, chemical machinery equipment, valves, vacuum pumps, pressure vessels, hydraulic cylinders, aerospace equipment, etc.

1. High temperature sealing

Modern industrial oil cylinders require high-temperature oil cylinder seals in many places, such as pressure casting oil cylinders, metallurgical oil cylinders, kiln oil cylinders, automotive engine seals, etc., with high temperatures up to around 300 ℃.

2. Low temperature sealing

Sealed with liquefied nitrogen, liquefied petroleum gas, liquefied carbon dioxide, liquefied oxygen, etc., with a low temperature of -200 ℃.

3. High pressure sealing

Super large tonnage press, high-pressure water cutting machine, air compressor, with a high pressure of up to 400MPa.

4. High speed sealing

High speed shaft, speed up to 30-40 Metre per second; High speed reciprocating oil cylinder, telescoping speed can reach 15-20 Metre per second.

5. Sealing of special working media

High temperature water vapor, seawater, brake oil, acid and alkali, etc.

6. Low friction

Typical examples include servo cylinders.

7. Long life sealing

Wind power pitch oil cylinder, building damping oil cylinder.

8. Sealing of large oil cylinder

Crane oil cylinder, stacker oil cylinder.

9. Sanitary sealing

At present, many seals in contact with food and drugs have been sealed with pan plugs.

10. Quick response oil cylinder

The installation groove of the sealing element is small, and the structural components of the oil cylinder can be lighter. At the same time, the friction resistance is small, which can greatly improve the dynamic performance of the oil cylinder and manufacture a better rapid response oil cylinder.

In summary, sealing ring springs play a crucial role in ensuring the reliable and efficient operation of various industrial equipment and systems across a wide range of applications.