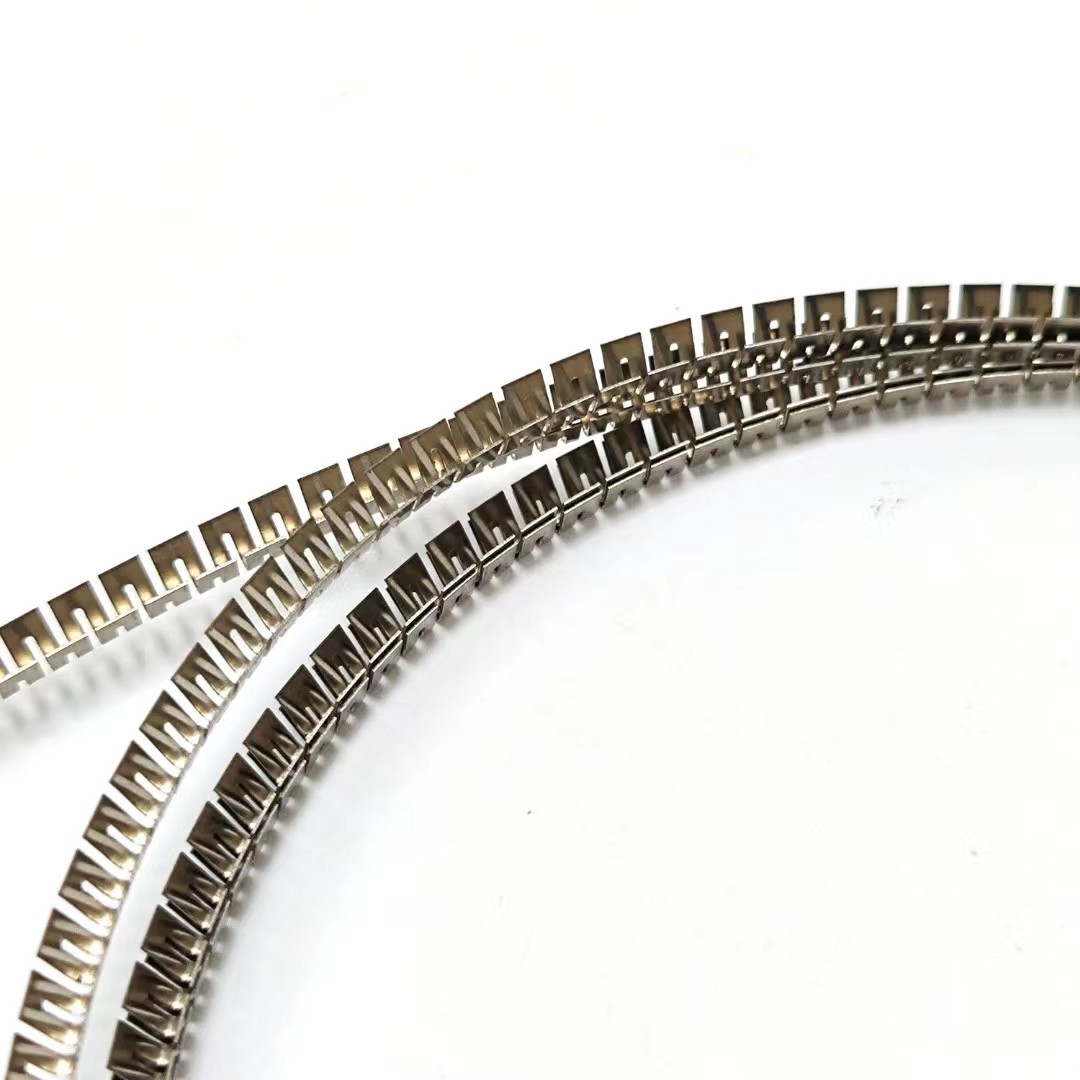

V-springs are precision sealing rings widely used in various manufacturing industries, including automotive and chemical industries. The unique design inside and outside of this oil seal allows it to perform excellent sealing function even in a pressure free state. This product mainly includes three parts: support ring, sealing ring, and pressure ring, all made of high-quality nitrile rubber or chloroprene rubber to ensure its durability and reliability. It is worth mentioning that this oil seal has the characteristic of self sealing, which can meet the sealing requirements without applying external pressure. Moreover, the sealing compression amount can be flexibly set by adjusting the clamping mechanism to adapt to various complex working conditions and media types, such as lubricating oil, water, gas, etc., which can effectively seal.

During the manufacturing process, precise control of parameters such as material selection, width, thickness, and length, as well as fine adjustment of clearances between support rings, compression rings, and coupling surfaces, are key factors determining the quality of V-spring. Therefore, in the production process, we will strictly control each parameter link to ensure that each product reaches the best quality level. And, when installing the V-spring, please make sure to adjust the tightening force correctly and maintain the fitting accuracy of the above aspects. If operated improperly, it may cause problems such as oil seal leakage and wear.

Therefore, we remind you to pay more attention when choosing and using this type of oil seal. In practical applications, this V-spring spring has been successfully applied in many fields, such as waterways, engines, transmissions, etc., which not only prevents oil and water leakage, but also ensures safe and efficient mechanical operation. In actual use, please follow the relevant installation, maintenance, and replacement guidelines to extend its service life and ensure stable operation of the machine.

V-springs find applications in various industries, including automotive, aerospace, electronics, and industrial equipment. They are used in situations where a compact, high-load spring solution is required, and they have to provide predictable and consistent force across a wide deflection range. These springs can be made from various materials, such as carbon steel, stainless steel, or other alloys, depending on the specific requirements of the application.