Canted Coil Springs in Medical Technology

Introduction

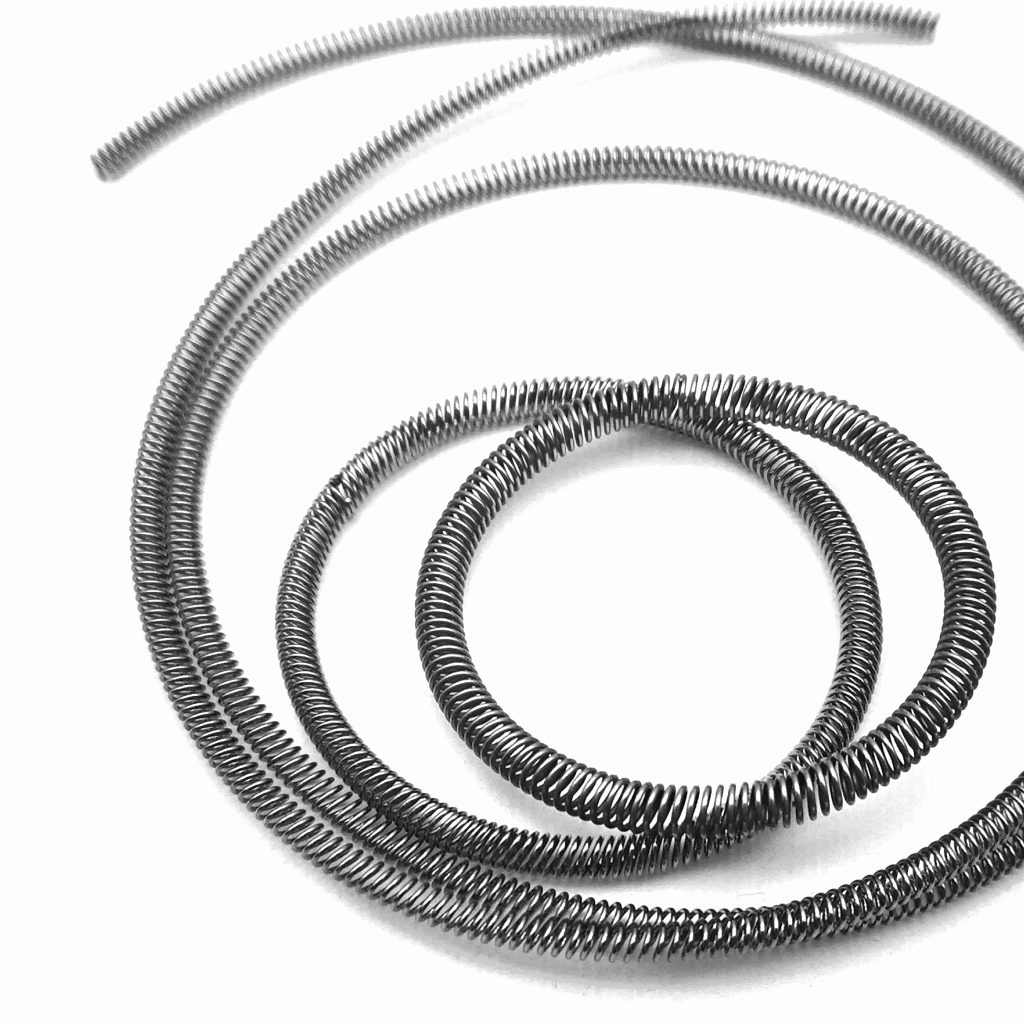

Canted coil springs are highly versatile mechanical components widely used in the medical device industry. Their unique helical structure, featuring canted or slanted coils, allows for precise force control, electrical conductivity, and secure mechanical engagement. These characteristics make them indispensable for various applications in implantable devices, surgical instruments, and advanced diagnostic tools.

The demand for medical-grade canted coil springs has surged in recent years due to their reliability, biocompatibility, and ability to function under extreme conditions. This article explores their applications, material considerations, benefits, and compliance with medical industry standards.

1. Key Applications in Medical Devices

1.1 Implantable Medical Devices

Canted coil springs play a critical role in implantable medical devices, where secure electrical and mechanical connections are essential. Common applications include:

- Pacemakers and Defibrillators: Used in battery and lead connectors to ensure a stable electrical interface.

- Neurostimulators: Provide electrical contact stability and flexibility in devices that stimulate nerves to manage chronic pain or neurological conditions.

- Cochlear Implants: Ensure reliable electrical connections in auditory implants, facilitating better hearing restoration.

- Cardiovascular Stents and Filters: Assist in deploying and securing implants in blood vessels, minimizing movement and ensuring structural integrity.

1.2 Surgical Instruments

Medical-grade canted coil springs are integral to various surgical instruments, ensuring precision, stability, and secure mechanical connections. Key examples include:

- Laparoscopic and Endoscopic Tools: Springs in locking mechanisms provide adjustable force and prevent instrument slippage during delicate procedures.

- Robotic-Assisted Surgery Systems: Used in articulating joints and connectors, allowing precise control and repeatability in minimally invasive surgeries.

- Biopsy and Retrieval Tools: Aid in grasping and releasing tissues with controlled force application.

1.3 MRI-Compatible Medical Devices

Magnetic Resonance Imaging (MRI) presents unique challenges for medical device components. Canted coil springs made from non-magnetic materials, such as titanium or beryllium copper, ensure compatibility while maintaining:

- Secure Electrical Connections: Essential in implants and external monitoring devices.

- Mechanical Reliability: Preventing movement or displacement during high-intensity magnetic fields.

- Durability and Corrosion Resistance: Ensuring longevity in medical applications.

1.4 Catheter and Endoscopic Devices

For minimally invasive procedures, flexibility and secure connectivity are critical. Canted coil springs improve:

- Maneuverability in Catheters: Enhancing articulation while maintaining stability.

- Secure Tube-to-Tube Connections: Enabling precise placement of guidewires and endoscopic instruments.

- Reliable Electrical Contacts: Assisting in sensors and diagnostic instruments requiring stable signal transmission.

In portable and implantable medical devices, canted coil springs provide consistent force and reduce electrical resistance, benefiting:

- Portable Defibrillators: Ensuring reliable power transfer in high-energy applications.

- Hearing Aids and Wearable Monitors: Enhancing battery life and connectivity.

- Medical Sensors: Facilitating accurate data collection in continuous monitoring systems.

2. Material Considerations for Medical Applications

The selection of material for canted coil springs in medical applications is crucial to ensuring performance, durability, and biocompatibility.

2.1 Stainless Steel 316L

- High corrosion resistance.

- Biocompatible and widely used in surgical implants.

- Maintains strength in sterilization environments.

2.2 Titanium and Titanium Alloys

- Lightweight and non-magnetic, making them ideal for MRI-compatible applications.

- Excellent biocompatibility and resistance to body fluids.

- Used in long-term implantable devices.

2.3 Beryllium Copper (BeCu)

- High electrical conductivity, making it suitable for battery contacts and electrical interfaces.

- Provides moderate corrosion resistance.

- Offers antimicrobial properties beneficial in medical environments.

2.4 Platinum-Iridium Alloys

- High durability and exceptional biocompatibility.

- Used in high-reliability applications such as pacemakers and neurostimulators.

- Resistant to oxidation and degradation inside the human body.

2.5 Nickel-Titanium (Nitinol)

- Offers shape memory and superelastic properties.

- Used in dynamic implants such as stents and orthopedic components.

- Resistant to deformation under repeated mechanical stress.

3. Benefits of Canted Coil Springs in Medical Devices

3.1 Precision and Consistency

- Provide uniform force application, essential in medical assemblies requiring exact load control.

- Improve reliability in surgical and implantable medical devices.

3.2 Electrical Conductivity

- Facilitate low-resistance electrical connections, ensuring stable signal transmission in implantable and diagnostic equipment.

- Reduce energy losses in battery-powered medical devices.

3.3 Secure and Repeatable Latching

- Used in surgical instruments and robotic systems for quick, secure attachment and detachment.

- Ensures stability in high-vibration environments.

3.4 Biocompatibility and Corrosion Resistance

- Meets stringent medical industry requirements for safe implantation.

- Resistant to bodily fluids, sterilization processes, and long-term degradation.

3.5 Compact and Lightweight Design

- Allows for miniaturization of medical devices.

- Reduces patient discomfort in wearable and implantable applications.

4. Future Trends and Innovations

4.1 Miniaturization for Advanced Medical Applications

- Increasing demand for smaller, more precise components in minimally invasive devices.

- Advanced manufacturing techniques such as micro-coiling for ultra-small canted coil springs.

4.2 Smart Medical Devices

- Integration of canted coil springs in IoT-enabled medical devices for real-time monitoring and data transmission.

- Use in advanced prosthetics and exoskeleton systems.

4.3 3D Printing and Additive Manufacturing

- Potential for customized and patient-specific spring designs.

- Rapid prototyping for faster development cycles in medical research.

Conclusion

Canted coil springs are revolutionizing the medical device industry by providing reliable mechanical and electrical solutions in implantable devices, surgical tools, and diagnostic equipment. Their ability to maintain consistent force, conductivity, and biocompatibility makes them essential for modern medical applications. With ongoing advancements in material science and manufacturing techniques, canted coil springs will continue to play a vital role in the evolution of medical technology.

For medical device manufacturers, selecting the right material and design specifications for canted coil springs is crucial for ensuring optimal performance and compliance with industry standards. As technology progresses, their role in enabling smarter, smaller, and more efficient medical solutions will only expand.