Helical Spring Overview

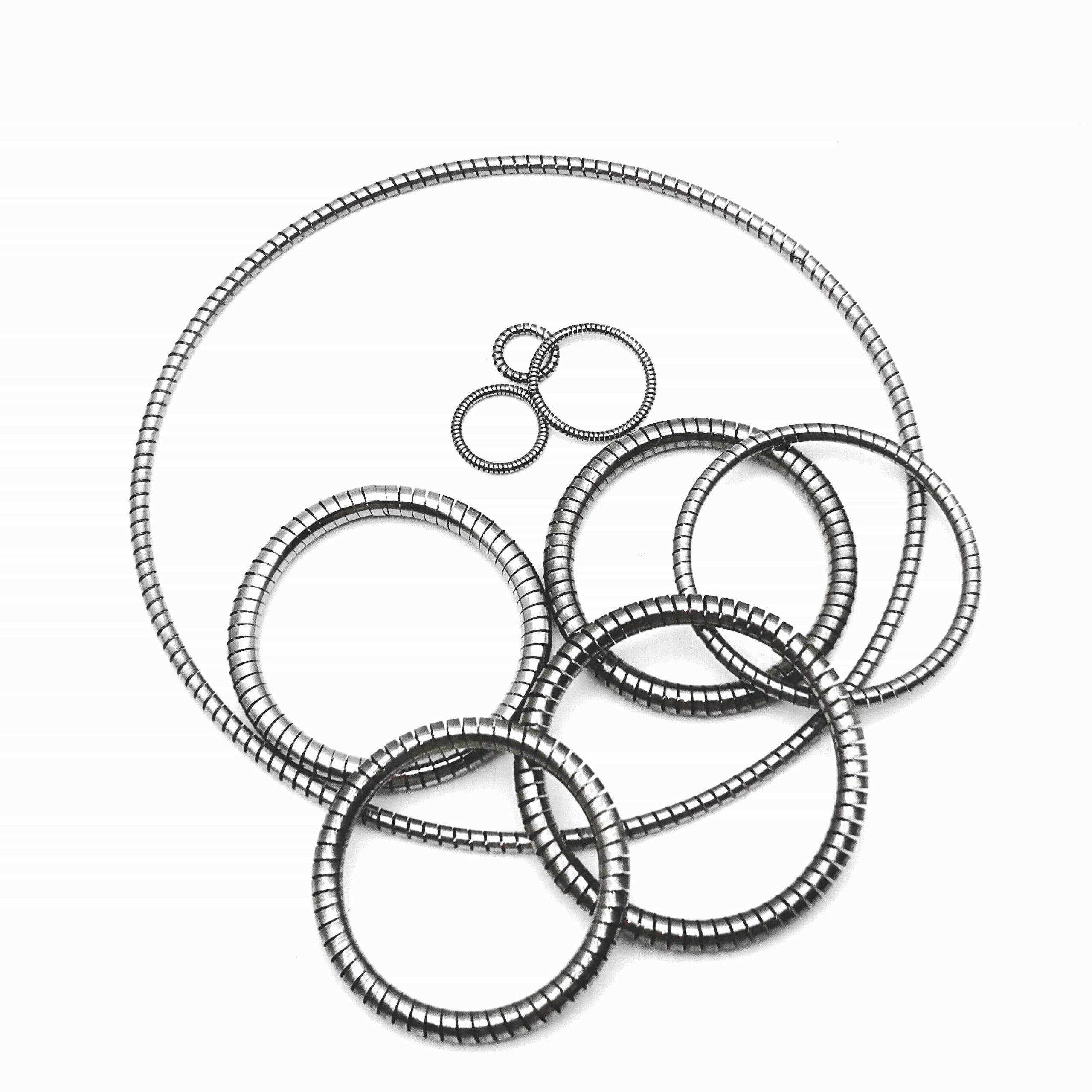

Handa Helical Spring is also known as: Wound Spring, Ribbon Spring, Helical Wound Springs.

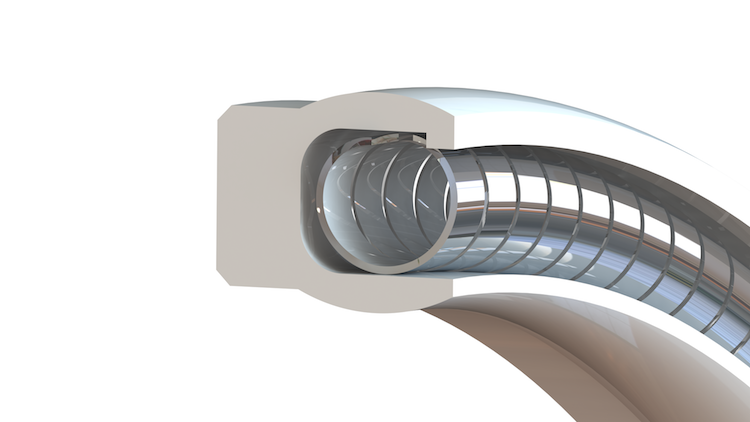

Helical Spring Seals are well-suited for static, low-speed, and cryogenic applications, offering positive sealing over a wide range of temperatures and pressures. They are particularly beneficial for applications requiring high unit loads and even load distribution across each individual band.

Helical spring plans create generously higher burden per inch redirection values when contrasted with the cantilever “U” & “V”– molded springs. Because of the outline way of the seal coat geometry these sorts of plans are fundamentally utilized for static and/or lower element seal applications.

Materials available include:

Stainless Steels

301 | 302 | 304 | 316 | 17-7PH

Exotic Alloys

Inconel (grades 600, 718, X-750)

Monel (grade 400)

Elgiloy/Phynox to AMS5833. Also available compliant to NACE MR0175.

Hastelloy (grades C22, C276, C2000)

Beryllium-copper,