The Helical spring is usually composed of the O-ring spring, and sealing groove, which work together to achieve the sealing function of the O-ring seal. The plug fills the sealing groove through its elastic deformation, while the spring provides restoring and compressive force, ensuring a tight fit between the plug and the joint surface, thereby achieving a reliable sealing effect. This structure is widely used in various industrial and mechanical applications to ensure sealing performance and prevent leakage.

O-ring seal springs are usually made of multiple materials, and the specific selection depends on the application requirements and environmental conditions.

①Rubber: Common rubber materials include Nitrile rubber, Fluoroelastomer, Silicone Rubber, etc. Rubber has good sealing performance and elasticity, suitable for various industrial and mechanical applications.

②Polyurethane: Polyurethane materials have excellent elasticity and wear resistance, suitable for sealing applications in high-pressure and high-temperature environments.

③Polytetrafluoroethylene (PTFE): PTFE is a material with good chemical resistance and low friction coefficient, commonly used in corrosion resistance and high-temperature sealing applications.

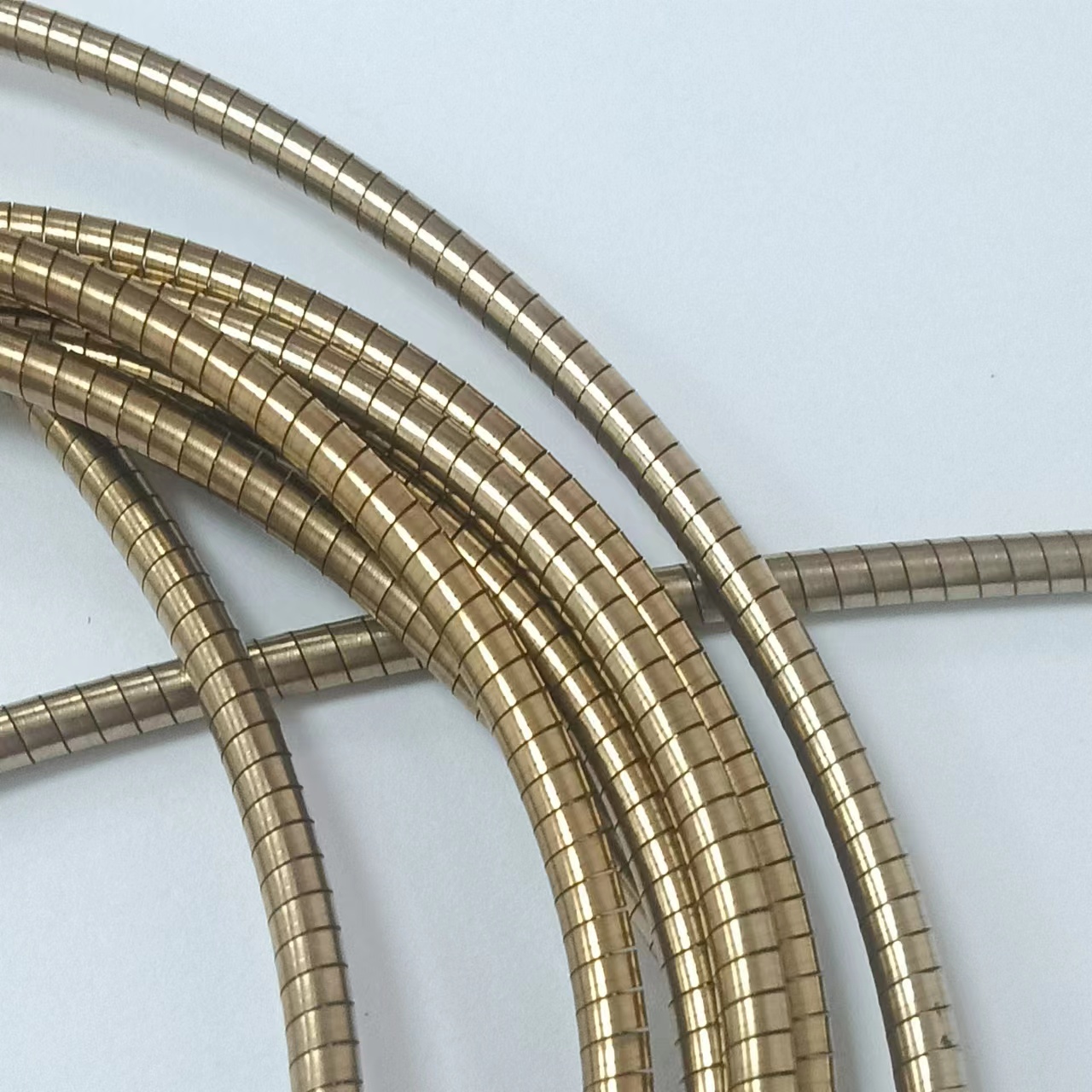

④Metal springs: Metal springs in plug sealed springs are usually made of stainless steel (such as 304 or 316 stainless steel), which has good elasticity and corrosion resistance.

These materials provide appropriate sealing performance and durability in different applications. According to specific application requirements and working environment, selecting appropriate materials is the key to ensuring the normal operation and long-term use of the O-ring spring.