Canted coil springs are a critical innovation in sealing technology, offering unique advantages in a wide range of industrial applications, especially in harsh environments such as aerospace, military, and high-performance machinery. Their ability to provide consistent sealing pressure and performance in extreme conditions makes them invaluable to engineers and manufacturers.

Canted coil springs are a specialized type of spring designed with coils that are wound at an angle to the spring’s central axis. This unique design enables them to offer superior flexibility and resilience compared to traditional springs, making them ideal for sealing applications where constant pressure is essential. These springs are often used in conjunction with elastomeric seals to create a spring-energized seal that ensures a tight, reliable seal under varying pressure and temperature conditions.

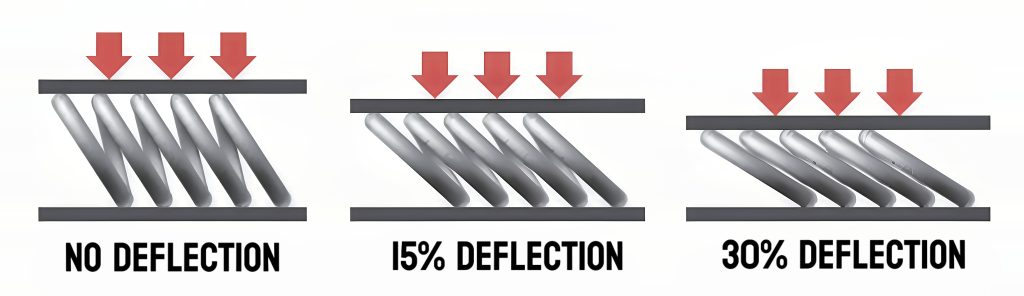

The design of canted coil springs is specifically tailored to accommodate both static and dynamic sealing needs, meaning they can provide effective sealing for both stationary and moving components. The inherent flexibility of the spring allows it to adjust to minor changes in the sealing surface, providing a consistent force over time.

Canted coil springs are commonly used in several critical industries due to their durability, reliability, and adaptability. Some of the primary applications include:

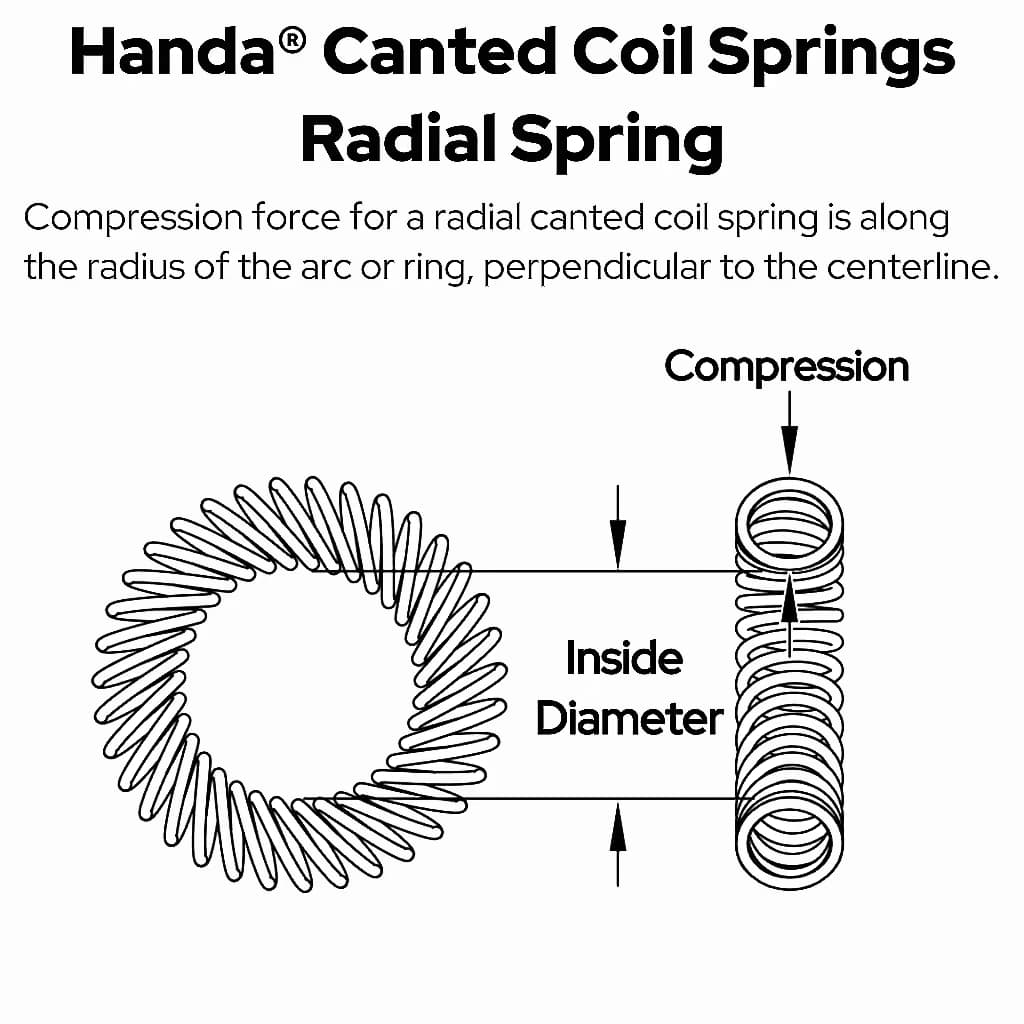

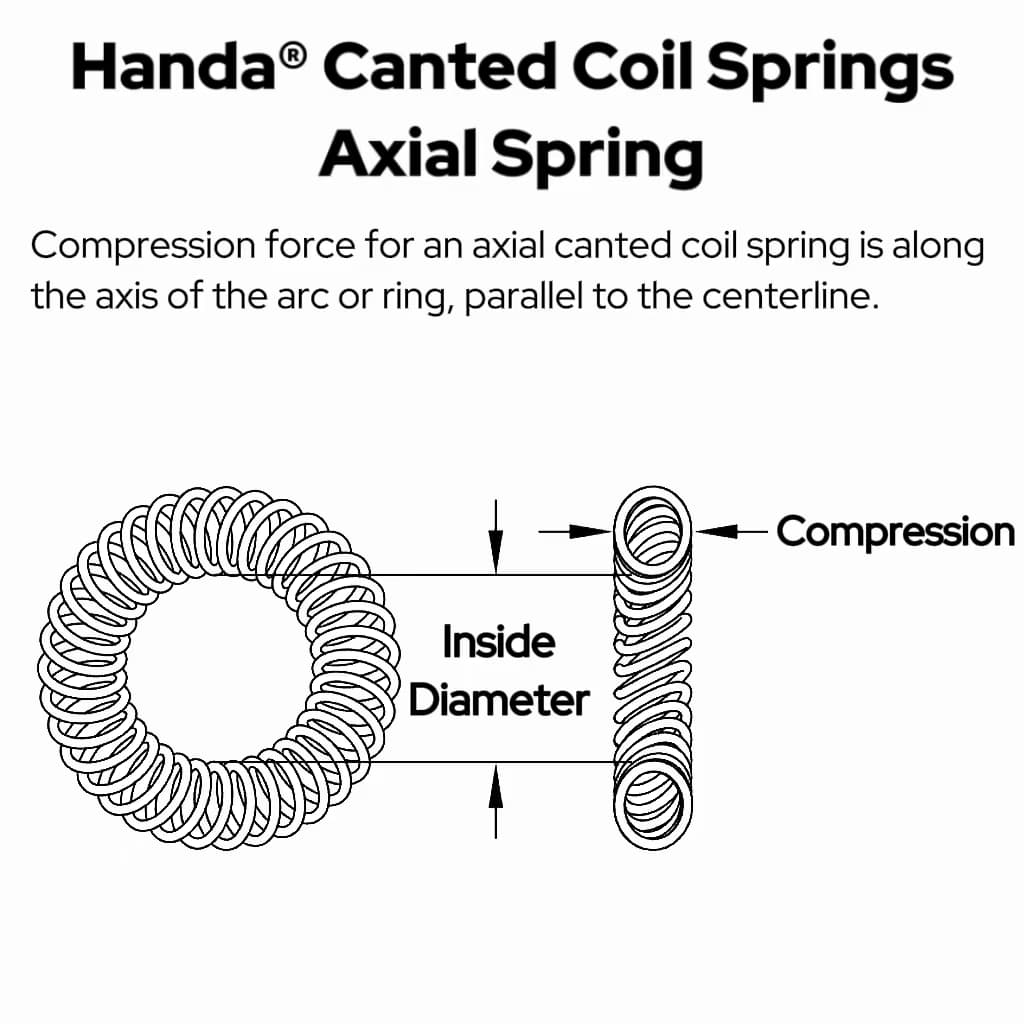

Canted coil springs function by applying continuous, even pressure around the sealing interface. As the spring coils are canted at an angle, they generate a uniform force that adapts to changes in the size or shape of the sealing surface. This makes them particularly useful for compensating for surface irregularities and ensuring a tight seal over time.

The spring material is typically made of high-quality stainless steel or other corrosion-resistant alloys, ensuring that the spring maintains its elasticity and sealing capabilities even under high temperatures or exposure to chemicals. The helical nature of the spring allows for significant flexibility, enabling it to endure cyclic movements or vibrations without losing its sealing effectiveness.

At Handa Spring, we offer canted coil seal springs in a wide range of diameters and custom sizes to meet the unique requirements of your projects. Whether you’re looking for springs to fit standard sealing systems or require specialized springs for more complex applications, we have the expertise and product range to deliver.

Explore our canted coil seal springs in different diameters to find the perfect match for your sealing needs.

At Handa Spring, we pride ourselves on offering high-quality slant coil springs that deliver exceptional sealing performance. Our products are manufactured using the latest technology and are designed to meet the rigorous demands of industries such as aerospace, automotive, and oil & gas. With our extensive range of customizable options, we ensure that each product meets your specific application requirements.

Additionally, we provide fast delivery and excellent customer support to ensure that your project runs smoothly from start to finish.

Learn more about our canted coil springs and how they can improve your sealing applications.

Canted coil springs are an essential component in modern sealing systems, offering versatility, durability, and performance in even the most demanding environments. By choosing high-quality springs like those offered by Handa Spring, you can ensure reliable, long-lasting sealing solutions for your critical systems.

For more information on canted coil springs and other sealing solutions, visit Handa Spring.