Detached leg springs are a unique and versatile type of spring mechanism used in a wide range of industries, from automotive to aerospace and beyond. Their distinctive design and function make them indispensable in mechanical systems that require precision, flexibility, and durability. This article provides a deep dive into the world of detached leg springs, their key features, applications, benefits, and material considerations.

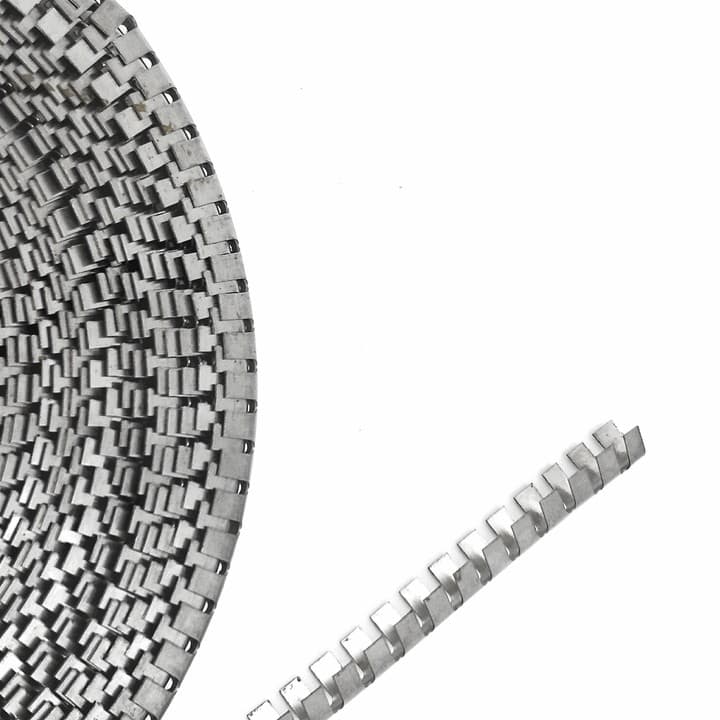

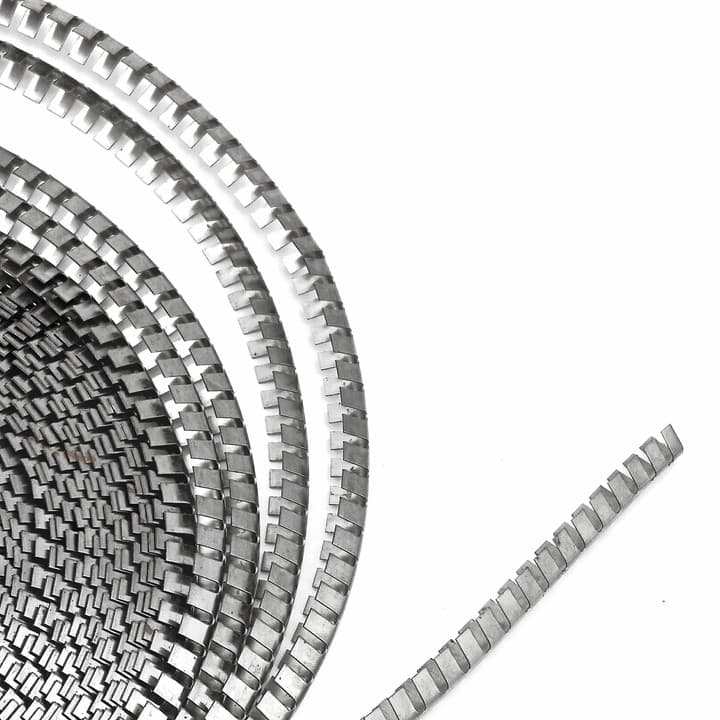

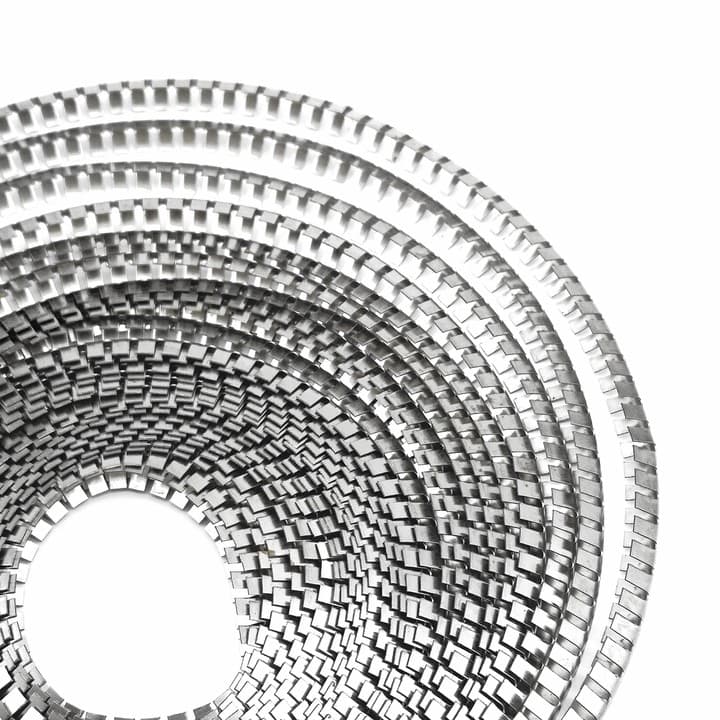

Detached leg springs, often referred to as fishback or independent leg springs, are mechanical springs characterized by the separation or detachment of the spring legs from fixed anchor points. Unlike traditional springs, where the entire coil or structure is bound at both ends, detached leg springs feature one or more legs that remain free, allowing them to flex independently. This unique design grants these springs significant versatility in motion control, load distribution, and energy absorption.

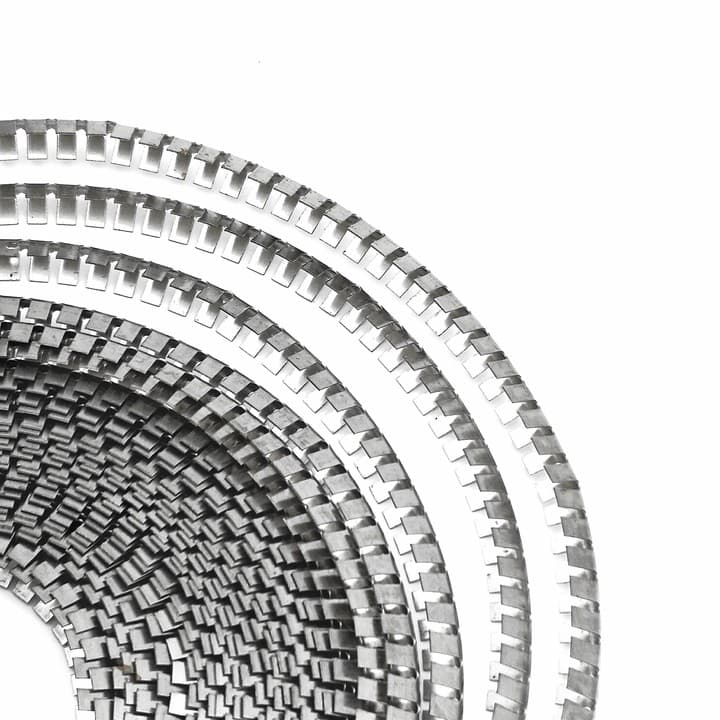

Detached leg springs are commonly made from high-grade materials such as steel, stainless steel, and special alloys that enhance their mechanical properties and resistance to wear, fatigue, and environmental damage.

The defining characteristic of detached leg springs is the independent movement of their legs. These legs are capable of flexing, bending, and absorbing forces without being fixed to an anchor at both ends, which allows for precise force modulation and flexible load distribution. This flexibility is particularly useful in applications that require fine control over mechanical motions or where dynamic stress needs to be absorbed.

Detached leg springs are designed to handle both light and heavy loads, depending on their construction and material properties. The number of legs, their thickness, and the material type all influence the load-bearing capacity of these springs. In industrial and automotive applications, where high load tolerance is critical, detached leg springs offer an optimal balance of strength and flexibility.

Another significant feature of detached leg springs is their ability to absorb and dissipate energy. In mechanical systems subjected to repetitive or sudden forces, such as vibrations or shocks, these springs can act as dampening devices, ensuring smooth operation and reducing stress on surrounding components.

Many detached leg springs are made from corrosion-resistant materials like stainless steel or alloy steels. This makes them suitable for use in harsh environments, including exposure to chemicals, moisture, and extreme temperatures. The durability of these springs ensures they can function effectively for extended periods, even under demanding conditions.

Detached leg springs can be customized to meet specific mechanical or environmental requirements. Engineers can adjust the spring’s leg length, diameter, material composition, and other features to optimize performance for different applications. This customizability makes them highly adaptable to various industry needs.

Detached leg springs are widely used across multiple industries due to their flexibility, load-bearing capabilities, and precise motion control. Below are some of the key sectors where detached leg springs are critical components.

In the automotive industry, detached leg springs play an essential role in vehicle suspension systems, brakes, and other mechanical components. These springs help absorb vibrations and shocks during driving, ensuring a smooth and comfortable ride. Additionally, their load-bearing properties make them ideal for supporting vehicle components that experience dynamic stresses.

Detached leg springs are frequently used in aerospace and defense applications due to their precision and ability to operate under extreme conditions. In aircraft and spacecraft, these springs are utilized in control surfaces, landing gear mechanisms, and other critical systems that demand high reliability and strength. Their lightweight yet durable nature makes them ideal for aerospace applications, where performance and weight considerations are vital.

In industrial machinery, detached leg springs help improve the efficiency and lifespan of machines by absorbing mechanical stress and vibrations. These springs are found in a variety of machinery, from heavy-duty manufacturing equipment to smaller precision devices, where they provide smooth operation, reduce wear and tear, and improve performance.

In the medical field, detached leg springs are often used in devices that require precise motion control and reliability. They can be found in surgical instruments, prosthetic devices, and diagnostic equipment. The fine-tuned motion provided by these springs ensures that medical devices function smoothly and efficiently, improving patient outcomes and operational safety.

In electronics, detached leg springs are employed in connectors, switches, and other components where fine-tuned force control and electrical contact are necessary. These springs can help maintain reliable electrical connections while allowing for movement or expansion in various components.

The performance of detached leg springs is heavily influenced by the materials used in their construction. Choosing the right material is crucial for ensuring the spring’s durability, flexibility, and load-bearing capacity.

Stainless steel is a popular material for detached leg springs due to its excellent corrosion resistance, mechanical strength, and durability. It can withstand harsh environments, making it ideal for applications where the spring is exposed to moisture, chemicals, or extreme temperatures.

Alloy steels offer enhanced strength and flexibility compared to standard steels. They can be engineered to provide specific properties, such as increased wear resistance or improved energy absorption, making them suitable for heavy-duty applications in industries like automotive and aerospace.

For applications requiring both lightweight and high strength, titanium springs are often used. Titanium offers excellent corrosion resistance and can operate under extreme temperatures, making it ideal for aerospace and high-performance engineering applications.

Phosphor bronze is a highly conductive material, making it suitable for electronic applications. It also offers good wear resistance and fatigue strength, making it a reliable choice for springs in electrical connectors and switches.

The adaptable nature of detached leg springs allows them to be used in a wide variety of industries and applications. Whether the need is for load-bearing, motion control, or energy absorption, these springs can be customized to suit specific requirements.

Detached leg springs are built to last. The materials used in their construction, such as stainless steel or alloy steels, ensure that they can withstand demanding mechanical forces and harsh environmental conditions over long periods.

These springs offer precise control over motion and force distribution. This makes them particularly useful in industries such as medical technology, aerospace, and automotive engineering, where exact control over movement is crucial.

In dynamic systems where sudden forces or vibrations are common, the springs excel at absorbing and dissipating energy, reducing stress on surrounding components and extending their operational life.

Detached leg springs can be customized in terms of material, size, and design, offering engineers the flexibility to tailor the spring to the exact requirements of their application.

Detached leg springs are a critical component in modern mechanical systems, providing the perfect balance of flexibility, load-bearing capacity, and durability. Whether in automotive suspension systems, aerospace control mechanisms, industrial machinery, or medical devices, detached leg springs play a vital role in ensuring smooth, reliable, and efficient operation. Their ability to absorb energy, manage dynamic forces, and offer precise motion control makes them indispensable in many industries.

Understanding the unique features and applications of these springs allows engineers and designers to make informed decisions when selecting the right spring for their specific needs. With their customizable options and robust material choices, detached leg springs will continue to be a versatile solution in engineering and design for years to come.