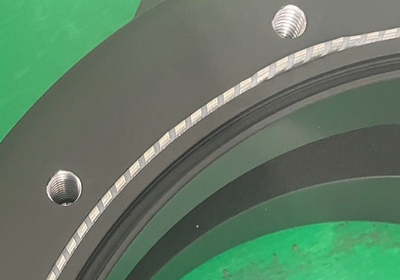

The electromagnetic sealing gasket is a kind of elastic material with conductive surface. Installing an electromagnetic gasket at the junction of two pieces of metal fills the gap and eliminates the conductive discontinuity.

After the electromagnetic sealing gasket is used, there are no larger holes in the gap, thereby reducing the leakage of high-frequency electromagnetic waves.

1) Reduce the requirements for processing and allow the flatness of the contact surface to be low.

2) Reduce the number of fastening screws at the junction to increase aesthetics and maintainability.

3) There will be no high-frequency leakage at the gap.

Although electromagnetic sealing gaskets can greatly improve gap leakage in many cases, if the contact surface between the two pieces of metal is machined (for example, milled) and the distance between the fastening screws is less than 3 cm, it is better to use electromagnetic sealing. Rear shielding effectiveness will not be improved because the contact resistance of this structure is already very low.

From the working principle of the electromagnetic sealing gasket, it can be known that the electromagnetic leakage of the gap using the electromagnetic sealing gasket is mainly determined by the conductivity of the gasket material and the contact resistance of the contact surface.

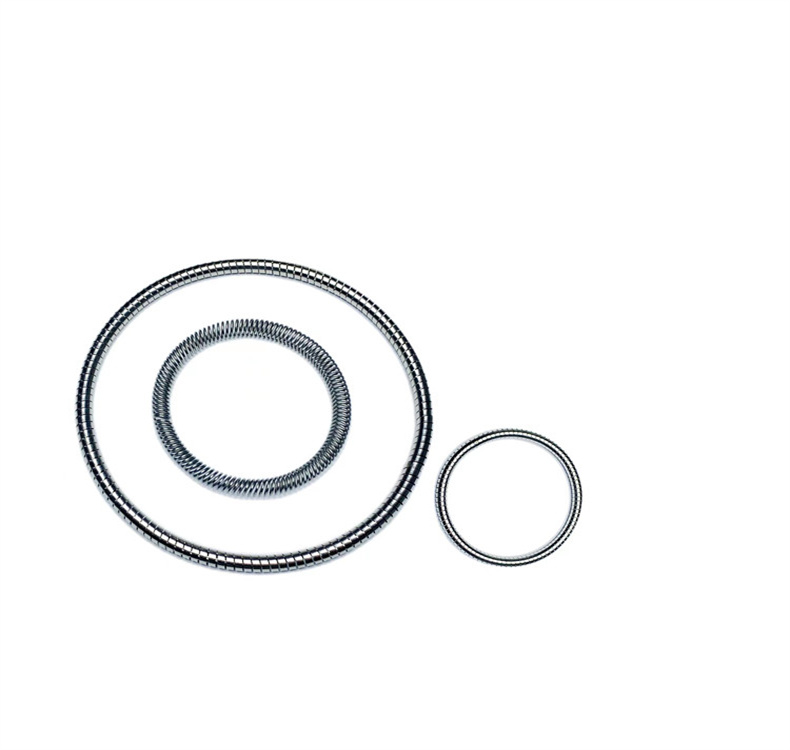

1) Choose a gasket material with good conductivity.

2) Keep the contact surface clean

3) Apply enough pressure to the pad (to ensure small enough contact resistance).

4) The thickness of the liner should be enough to fill the largest gap

Flexible Application of Electromagnetic Seal Gasket

Unless the requirements for shielding are very high, it is not necessary to continuously use the electromagnetic sealing gasket at the gap. In practice, gaskets can be installed at intervals according to the requirements of shielding effectiveness, and the leakage of small holes formed between each section of gasket can be calculated by the previous formula. Carefully adjust the gasket spacing on the prototype to meet the shielding requirements and minimize the cost. For civilian products, the spacing between pads can be between λ/20~λ/100. Military products are generally installed continuously.