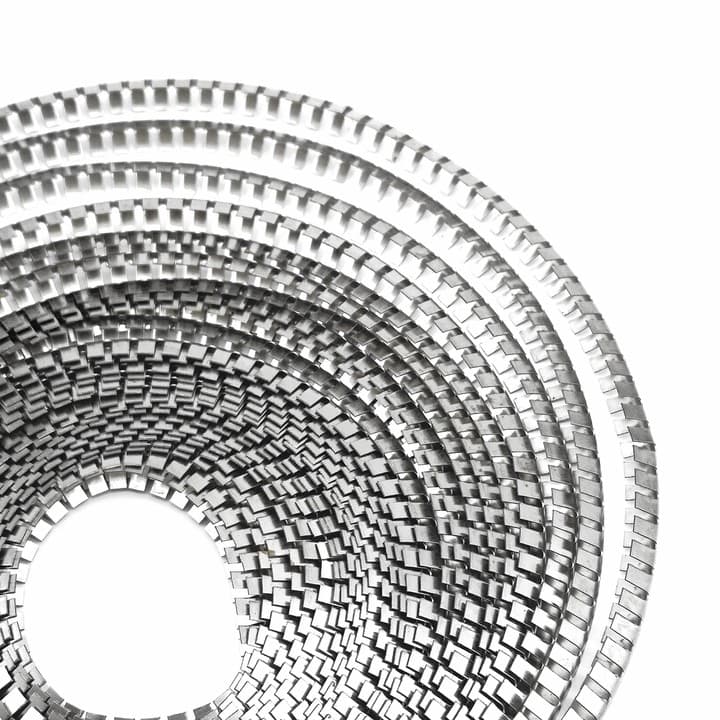

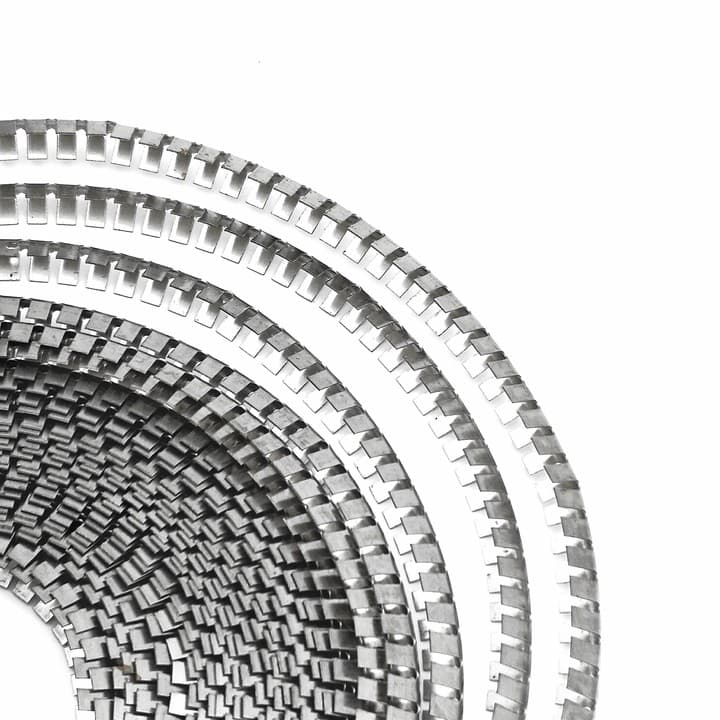

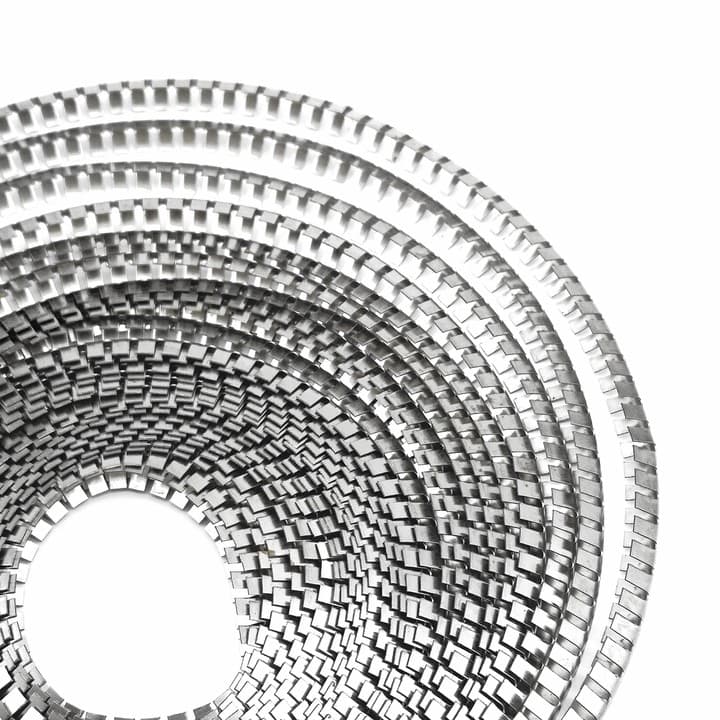

Detached Leg Springs

Detached leg springs, often referred to as fishback springs, represent a specialized type of spring design that offers distinct advantages in various engineering applications. Unlike traditional springs, these components feature a unique structural design that includes separated “legs” or support parts, which are detached from the main body of the spring. This innovative design provides enhanced flexibility, load-bearing capacity, and precision control in demanding applications.

In this article, we will delve deeper into the functionality, design, applications, specifications, and best practices for detached leg springs, illustrating their value and versatility in a range of industries, including automotive, aerospace, industrial manufacturing, and more.

Detached leg springs are known for their distinct features, which make them suitable for applications that demand heavy load capacity, flexibility, and precise control. Below are the key aspects that define their design and functionality:

One of the most noticeable characteristics of detached leg springs is the separation of the “legs” or the support arms from the main body of the spring. This separation allows the spring to be installed in a more flexible and configurable manner compared to traditional spring designs. The detached legs provide a better distribution of forces and offer enhanced resilience under high loads. They also allow for easier integration into complex systems where space constraints or specific geometries require careful consideration.

Another significant feature of detached leg springs is their heavy load geometry, which enables them to handle large forces over a wider deflection range. The geometry of the spring is optimized to ensure that the forces are evenly distributed across the spring’s structure. This makes them highly suitable for applications where substantial weight or pressure needs to be absorbed or supported, such as in industrial machinery, automotive suspensions, or high-load sealing applications.

Like other types of springs, detached leg springs undergo elastic deformation when external forces are applied. This means that when the spring is compressed or extended, it stores potential energy, which is released when the spring returns to its original shape. This elastic energy storage and release mechanism allows detached leg springs to be used effectively in systems where energy absorption, buffering, or controlled release is required.

Detached leg springs are well-suited for applications that require precise control over mechanical motion or load-bearing behavior. The unique design allows for fine-tuning of spring characteristics, making them ideal for environments where exact force, tension, or displacement control is necessary. This characteristic is particularly important in industries like aerospace, telecommunications, and high-precision manufacturing, where even minor deviations can lead to system failure or performance issues.

Due to their distinctive design, detached leg springs are employed in a variety of static and dynamic applications across multiple industries. Below are some of the key applications where detached leg springs offer significant advantages:

Detached leg springs are highly versatile and can function in both static and dynamic environments. In static applications, they are used to support stationary loads, maintaining force equilibrium and ensuring stable operation. In dynamic applications, where the spring must absorb or store energy due to motion or vibration, detached leg springs perform exceptionally well due to their high deflection range and flexibility.

For example, in automotive systems, detached leg springs can be used in shock absorbers or suspension systems, where they must handle both constant static loads (such as the weight of the vehicle) and dynamic loads (such as shocks from the road).

The unique design of detached leg springs makes them ideal for sealing applications. The springs’ ability to maintain contact and apply force across a range of surfaces ensures a reliable seal in various environments. In high-temperature, high-pressure, or EMI-sensitive environments, detached leg springs can be used to seal enclosures, joints, or gaps, preventing contamination or interference.

For instance, in electronics enclosures, these springs can be used for EMI shielding, providing both physical protection and electromagnetic interference prevention. The ability of detached leg springs to maintain their form and functionality under a wide range of conditions makes them essential for applications where sealing integrity is critical.

Detached leg springs are also highly suitable for systems that require precise control over force or movement. Their ability to deliver consistent, predictable performance across a range of deflections allows them to be used in applications such as actuators, precision instruments, or load-balancing systems. In precision control systems, such as those found in aerospace or robotics, the ability to fine-tune the spring’s mechanical behavior is crucial for achieving the desired performance.

When using detached leg springs, it is important to consider several factors to ensure optimal performance and longevity. The following points are crucial when designing and maintaining systems that incorporate these springs:

As with any spring, detached leg springs undergo elastic deformation when subjected to external forces. This deformation allows the spring to store energy, which is released as the spring returns to its original shape. However, excessive deformation can cause the spring to lose its elasticity, leading to reduced performance or permanent damage. It is important to design systems with the spring’s maximum deflection and load-bearing capacity in mind to avoid overstressing the material.

Proper installation of detached leg springs is critical to their performance. Ensuring that all components are correctly positioned and secured is essential to prevent loosening, misalignment, or failure during operation. Detach leg springs often require precise positioning to ensure that the detached legs are functioning as intended and that the spring can effectively absorb or release energy.

Additionally, the surrounding structure must be designed to accommodate the spring’s deflection range and load capacity. Misalignment or improper mounting can lead to uneven wear, reduced functionality, and ultimately system failure.

Like all mechanical components, detached leg springs require regular maintenance and inspection to ensure they continue to function effectively. Over time, springs may experience wear due to repeated deformation, changes in temperature, or exposure to chemicals or environmental factors. Regular inspections will help identify any potential issues, such as cracks, corrosion, or loss of tension, allowing for timely repairs or replacements.

Before selecting a detached leg spring for a particular application, it is important to ensure that the material and design are suitable for the operating environment. Factors such as temperature, humidity, corrosive substances, and mechanical stresses all play a role in determining whether a spring is appropriate for a given application. Many manufacturers offer springs made from different materials, such as stainless steel, Elgiloy® (a highly resistant alloy), or other high-strength metals, allowing for greater customization based on environmental conditions.

Detached leg springs are manufactured by a variety of companies, each offering different specifications, materials, and custom options. Some of the notable manufacturers include MW Components, which offers a selection of detached leg springs in multiple sizes and materials, including 301 stainless steel and Elgiloy®.

Key specifications that manufacturers commonly offer include:

To ensure the optimal performance and longevity of detached leg springs, it is essential to follow best practices for installation, maintenance, and use:

Understanding the working principle of detached leg springs is crucial to ensure their proper use. These springs are designed to provide energy storage and release while maintaining elastic deformation. Overloading the spring or using it outside its design parameters can result in permanent deformation, loss of performance, or failure.

Ensure that all components are properly aligned and secured during installation. Misalignment or improper installation can lead to uneven wear or failure during operation.

Inspect detached leg springs regularly for signs of wear, corrosion, or damage. Regular maintenance is crucial to keeping the spring in optimal condition, ensuring long-term reliability and performance.

Before selecting a detached leg spring, ensure that it is suited to the environmental conditions of the application. Whether the spring will be exposed to extreme temperatures, humidity, or corrosive chemicals, verifying material compatibility is essential for long-lasting performance.

Detached leg springs, with their unique design and versatile applications, offer significant advantages in handling heavy loads, providing precise control, and ensuring reliable performance in dynamic and static environments. Their flexibility, high load capacity, and precision make them invaluable in industries ranging from automotive to aerospace and beyond.

While detached leg springs come with certain installation and maintenance requirements, understanding their design, functionality, and best practices can help engineers optimize their use. Whether you’re designing a suspension system, sealing an enclosure, or developing a high-precision control system, detached leg springs provide an effective and reliable solution for demanding applications. With advancements in materials and customization options, these springs are poised to remain a critical component in complex engineering systems for years to come.