Water jets, as high-pressure water jet cutting equipment, rely on the performance of their accessories to ensure cutting efficiency and precision. V Springs, with their unique structure and excellent performance, have become a crucial component in water jet accessories.

Structure and Materials

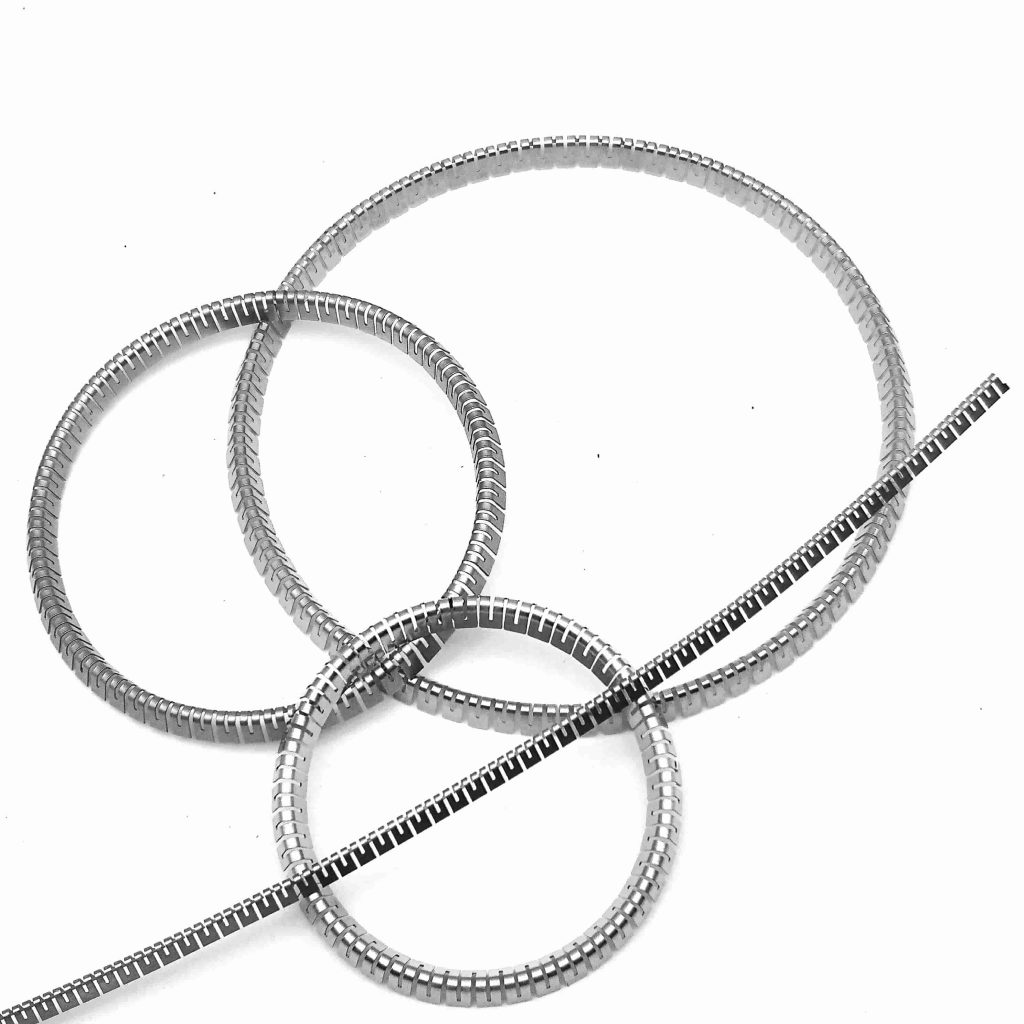

- Structural Features: V Springs are made from thin metal sheets and designed in a V-shape. Acting as cantilever leaf springs within a sealed housing, they concentrate energy and load at both ends.

- Common Materials: They are often made from materials such as Inconel X-750 or Elgiloy (cobalt-based alloys), which exhibit excellent high-temperature resistance, capable of withstanding temperatures up to 650°C.

Working Principle

In water jet accessories, V Springs are primarily used for sealing and vibration damping. As sealing elements, the elastic bending of their V-shaped cross-section provides radial support, ensuring that the sealing lip remains in close contact with the sealing surface. This effectively prevents water leakage during high-pressure water jetting. Additionally, through their elastic deformation, V Springs can absorb the vibration energy generated during the operation of water jets, reducing the impact of vibrations on other components and playing a role in vibration damping and noise reduction.

- High Stiffness and Load-Bearing Capacity: V Springs have a high stiffness, with a stiffness coefficient typically ranging from 500 to 2000 N/mm, enabling them to withstand ultra-high pressures. In water jets, which require the generation of high-pressure water flows, V Springs can effectively maintain sealing performance and prevent high-pressure water leakage. They are also widely used in similar ultra-high-pressure environments, such as nuclear power main pump seals and supercritical CO₂ turbine valve seals.

- Good High-Temperature Adaptability: Thanks to their shape design and selected materials, V Springs perform well in high-temperature environments and are not prone to deformation or performance degradation due to heat, meeting the requirements of water jets in some high-temperature operation scenarios.

- High-Frequency Vibration Suppression: Water jets may generate high-frequency vibrations during operation. The high stiffness of V Springs allows them to effectively reduce the risk of resonance, making them suitable for scenarios with vibrations above 200 Hz and ensuring the stability and reliability of water jet equipment.

Specific Applications in Water Jet Accessories

- Sealing System: The sealing system of water jets is crucial for the normal operation of the equipment. V Springs are widely used in water jet seals, such as PTFE spring-energized seals. Working in tandem with the sealing lip, they provide radial elastic support, ensuring a good contact between the sealing lip and the sealing surface. Even under high pressure, high temperature, and the frequent reciprocating motion of the water jet nozzle, they can effectively prevent high-pressure water leakage, improving sealing performance and service life.

- Vibration Damping Components: If the vibrations generated during the operation of water jets are not controlled, they can affect the precision and stability of the equipment and may even cause component damage. V Springs can be installed at the connection points or support positions of key water jet components, such as the connection between the cutting head and the body or the base of the high-pressure pump. By elastically deforming, they absorb and buffer vibration energy, reducing the transmission of vibrations to other components, thereby decreasing the overall vibration level of the equipment and improving its operation precision and reliability.

From structural design to practical application, V Springs demonstrate a high degree of adaptability to the working environment of water jets. If you would like to learn more about the specifications, models, or customization services of V Springs, please feel free to contact us(qinjunchang@handaspring.com).